In order to improve the decoration and weather resistance of the topcoat layer, the metallic flash topcoat should be applied on the middle coat, and it is not suitable to be directly applied on the cathodic electrophoretic primer film based on epoxy resin. For the defects of the topcoat film caused by the defects of the intermediate coating film (particles, sanding lines, dust, etc.), the metallic flash color is more difficult to repair than the natural color. To eliminate the defects (particles, flow marks, etc.) of the intermediate coating film, the usual method is grinding, and at the same time improve the smoothness of the coating film to improve the adhesion and decorative appearance of the top coat coating film. (Related Instrument: Adhesion Tester)

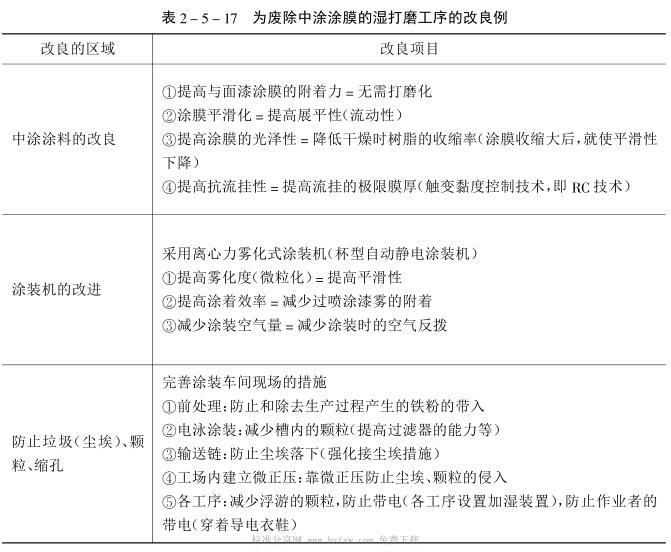

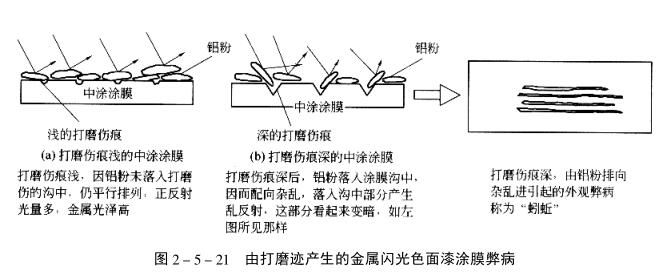

There are two ways of sanding, wet sanding and dry sanding. Before the 1980s and 1990s, the sanding of intermediate coatings was mainly wet sanding. Due to the large labor intensity and manual labor of grinding, and it is easy to produce grinding lines (scars), with the advancement of technology, the wet grinding of the intermediate coating film is gradually abolished (related equipment: Wet Film Applicator), and the improved examples are listed in In Table 2-5-17, at present, inspection is mainly used for grinding (or semi-dry grinding). The deep sanding pattern cannot be buried when the topcoat is applied, and it becomes an appearance defect. The white color with large pigment particles is not very conspicuous, but the pigment particles such as blue and green are small, and the dense color with low hiding power is easy to be conspicuous. This appearance disadvantage is particularly noticeable when a metallic iridescent finish is applied. As shown in (b) in Fig. 2-5-21, when the scratches of the grinding lines are shallow, the aluminum powder can still fill the scars and arrange them in parallel, the amount of regular reflection light is large, and the normal coating surface is still maintained. In the case of deep grinding scars, because the aluminum powder has a large particle size and is flat and thin, it falls into the groove of the deep grinding scars, and the arrangement direction is disordered. As shown in (b) in Figure 2-5-21, the reflected light of the aluminum powder is chaotic, and the part with a high angle is dark, resulting in the disadvantage of "earthworm" appearance of the coating film.