RDS 182.9μm L610φ 6.35mm production line rod formed

Production process Extrusion process, wet film thickness 182.9μm, main rod diameter 6.35mm, Total length 610mm, effective Spreader width 510mm, clamping length at both ends 50mm, material stainless steel 303.

RDS

RDSIntroduction

RDS 182.9μm L610 Φ6.35mm production wide-wound drawdown Bar is mainly used for quantitative control of fluid in the production process. For uneven pre-coating, this production-type metering bar can solve this defect. The production-type metering rod is uniquely formed with a fixed groove to wipe off excess fluid, thereby achieving the effect of a smooth coating.

RDS182.9μm L610 Φ6.35mm production-type wire rod has a coating film thickness of 182.9 μm, a Total length of 610 mm, and a diameter of 6.35mm . It is made of high-grade stainless steel and has no chrome plating on the surface.

Advantages

1. The RDS company has been focusing on the research and development of coating metering rods for 80 years, and has a high degree of market familiarity. It is used in most domestic (CN) industries and has a good market reputation;

2. By default, stainless steel 303 is preferred for measuring rods used in production. The wear resistance is much higher than that of low-priced rods, and it is cheaper in cost accounting;

3. The coating metering rod produced by RDS in the United States is very good in product process control, and the precision of the wet film marked by it is high (like the 800w pixel of the 1300w pixel VSIphone of a domestic (CN) brand-name mobile phone)

Applicable industry

| specialty paper | fine print paper wallpaper, wall paint, wall material, Book cover, book cover, book cover, |

| Plastic film substrate | Silicone Release Sticker adhesive tape protective film, protective tape Glass curtain wall film, thermal insulation film, window film, (coloring and protection) Photovoltaic film (solar panel) Pressure sensitive sheet car logo, car sticker cardboard packaging projection screen, screen, display screen thermal label sticker thermal transfer ribbon Tickets, labels, cardboard flexible packaging |

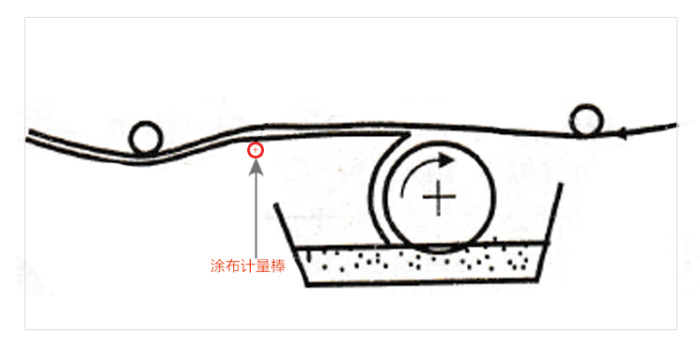

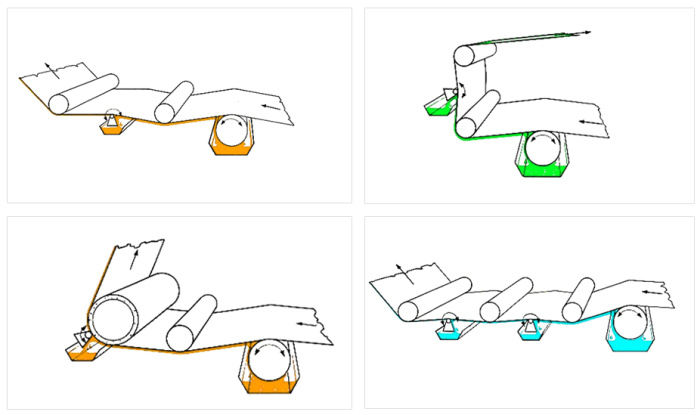

Principle of use

The quantitative control of the fluid during the production process makes the pre-coating smoother. The schematic reference is as follows:

real shot

Remarks: If you need to customize, please click [ wire rod custom quoter ]

RDS 182.9μm L610 Φ6.35mm custom wire rodSpecifications

| LIST | VALUE |

|---|---|

| Production process | Extrusion process |

| WFT | 182.9µm |

| Main rod diameter | 6.35mm |

| Total length | 610mm |

| Effective Application Width | 510mm |

| Grip Length | 50mm |

| material | Stainless steel 303 |

RDS 182.9μm L610 Φ6.35mm custom wire rod Packing list

Stainless Steel Rod X1 Transparent Encasement Hose X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- RDS Mayer Rods preparatory passivating film

- One article introduces RDS Applicator rod type and FAQ

- The experimental case of OSP Mayer Rods at inks Moulding [with video]

- Laboratory small coater film video demonstration on Aluminum Panel

- Application of laboratory coater on release paper with glue [video demonstration]

- What problems should I pay attention to when buying a wire rod applicator?

- Frequently Asked Questions for Inventory 2022 Lines, Issue 1

- Mayer Rods VS Film Applicators

- Experimental film coating machine case | Scrape coating slurry on release film

- Pull wire test