LANDTEK Shore Durometer testing device SHS-1 (D type) D type Shore Durometer dedicated

The LANDTEK SHS-1 Shore Durometer testing device is dedicated to the D-type Shore Durometer.

LANDTEK

LANDTEK-

Shore rubber Hardness Gauge HS-D Haibao D Shore rubber Hardness Gauge High Hardness Material Test

$ 432.00 -

HBO HS-AM digital Shore AM hardness gauge rubber plastic hardness gauge thin sample test

$ 877.00 -

Hypertherm HS-A digital display Shore A type rubber durometer with test bracket

$ 432.00 -

SUNDOO SLX-A Shore Durometer testing device A/C Shore Durometer for

$ 176.00 -

LEEBA-J hardness testing table Type A Shore Durometer for

Login

Overview

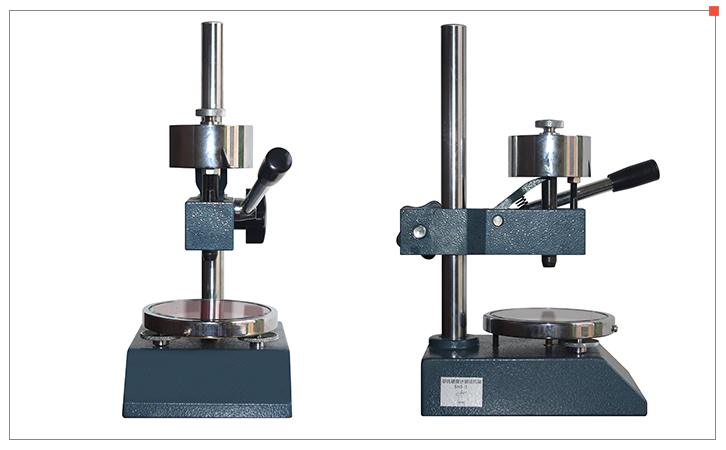

LANDTEK SHS-1 Shore Hardness Tester Test Rack is a test bracket used to improve the accuracy of rubber hardness measurement of Hardness Tester for Shore Hardness Tester D. The test force is applied to the weight on the central shaft of the pressure needle of the Hardness Tester by the SHS-1D Shore Hardness Tester test frame, so that the pressure of the Hardness Tester is pressed on the sample, so as to achieve a stable and accurate hardness value. GB/T531.1-2008 stipulates that the total mass of the weight and Shore Hardness Tester of the spring test force applied on the D-type Hardness Tester reaches 5kg.

Product configuration

LANDTEK SHS-1 D-type Shore Hardness Tester test frame consists of the following accessories: locking screws, fixed load weights, operating handles, screws, nuts, beams, Hardness Tester clamping rods, beam locking handwheels, columns, glass tables, and adjustment nuts.

Operating Principle:

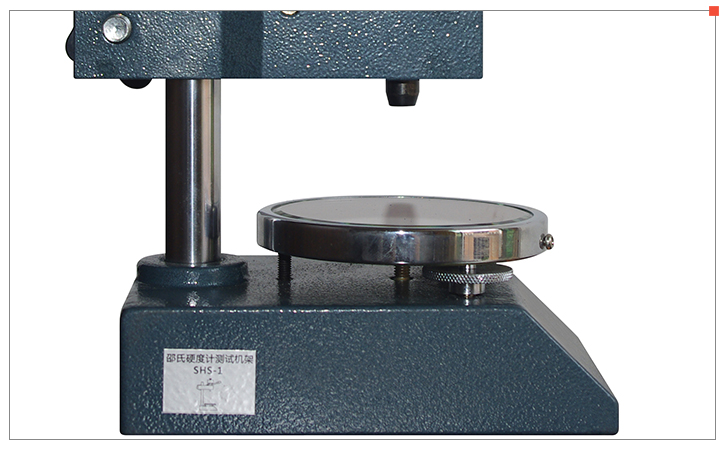

1. Install the connecting hole at the lower part of the clamping rod through the Hardness TesterSecurely attach the D-Shore Hardness Tester to the test rack and place the accessory Hardness Gauge block in the D-Shore Hardness Tester box on the glass work surface.

2. Press down the operating handle of the Shore Hardness Tester test rack, so that the hardness block is pressed down under the action of the fixed load weight, and the pressure of the D-type Shore Hardness Tester is aligned and enters the hole of the hardness block untilWhen the pressure foot of the Shore Hardness Tester is in full contact with the gauge plane. (Note:If the Hardness Tester is not equipped with a Hardness Gauge block, the operating handle can be depressed so that the D-type Shore Hardness Tester is pressed against the worktop under the action of the fixed load weight. Similarly, the Hardness Tester should be fully pressed into full contact with the plane of the glass table.)

3. At this moment, the D-type Shore hardness count value should be indicated within the hardness ±1 of the hardness measurement hole. If the hardness of the marking is not within ±1, the indication value can be adjusted to within 100±1 by using two adjustment nuts under the glass table.

4. Place the measured sample in:SHS-1 Shore Hardness Tester for racksOn the glass table, the operating handle is pressed down, and the hardness value is read at the specified time after the Hardness Tester is in full contact with the test specimen by the action of the fixed weight. (In general, the reading time is 15 seconds for thermoplastic rubber, 3 s for vulcanized rubber or other position type rubber, and 1 second after receiving the test load for microporous materials)

Actual picture of the product

LANDTEK SHS-1 (Type D) Shore Shore DuroMeter testing deviceSpecifications

| LIST | VALUE |

|---|---|

| Available Sclerometers | D type Shore hardness Tester |

LANDTEK SHS-1 (Type D) Shore Shore DuroMeter testing device Packing list

Hardness gauge bracket x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- CM-8822 Landtek Coating Thickness Gauge

- Comparison table of each model of LANDTEK Thickness Gauge [Selection Guide]

- ActiveASTM -2022

- ActiveJJF 2075-2023

- ActiveJJF 2074-2023

- ActiveKS MISO 868-2001

- ActiveGB/T 603-2023

- ActiveGB/T 2411-2008

- ActiveJB/T 6148-2017

- ActiveASTM D2240-2021

- ActiveDIN 53505-2000

- ActiveASTM D2240-2021

- ReplacedGB/T 2411-1980

- ReplacedJB/T 6148-1992

- ActiveGB/T 531.1-2008

SHS-1 (Type D)

SHS-1 (Type D)