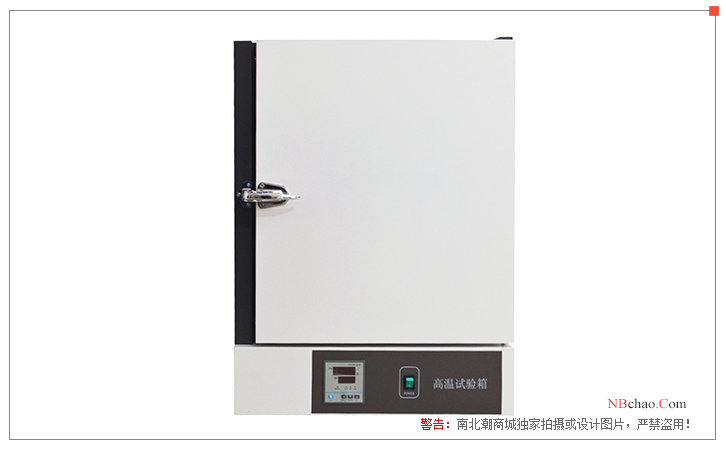

Shanghai JIECHENG DHG-9078A high temperature Drying Oven 500 ℃/70L

Shanghai JIECHENG DHG-9078A high temperature Drying Oven has 100~500 ℃ Temperature range, 70L volume, shelf (standard) 2 pieces. In addition, DHG-9078A also has 0.1 ℃ Temperature resolution and +/- 0.1 ℃ fluctuation, input Power 1600W.

JieCheng

JieCheng-

Kenton KH-75A digital electric air blowing dryer 250 ℃/225L

$ 520.00 -

YIHENG BPZ-6213 Vacuum oven vacuum heat treatment equipment for electronic products

$ 4901.00 -

YIHENG PH-140A Drying and Incubating Oven 2050W input power

$ 836.00 -

BENTING CBX45B Hot Air Disinfection Box 1.2kw/45L

Login -

Kenton KH-35AS digital electric drying oven 40L with independent temperature limiter

$ 392.00

Shanghai Jiecheng DHG-9078A high temperature Drying Oven has a temperature control range of 100~500°C, a volume of 70L, and 2 load carriers (standard). In addition, the DHG-9078A also has a temperature resolution of 0.1°C and a fluctuation of ±0.1°C, with an input power of 1600W.

Features

★ The inner tank is made of 304 stainless steel, which does not rust

★ Intelligent controller, good temperature control effect, a large number of exports to European countries

★ Digital one-screen display, temperature, time and other parameters

★ After-sales service is guaranteed, and after-sales service is available all over the country (except for townships)

★ Streamlined luxury machine shape with aesthetic design concept, electrostatic spraying box, and tempered glass observation window with large Viewing Angle on the door

★ It is made of mirror stainless steel argon arc welding, and the box is made of good steel plate, which is beautiful and novel. Mirrored stainless steel lining, the instrument will never be corroded.

★The large LED LCD screen displays the set parameters and measured parameters

★ High-performance thermostatic function to avoid evaporation and drying of samples

★ The new synthetic silicon sealing strip is adopted, which can operate at high temperature for a long time, has a long service life and is easy to replace.

★ Natural convection is used to form a suitable air duct to improve the temperature uniformity in the studio.

★ The cargo carrier in the box can be adjusted freely

Introduction to controls

★ The microcomputer P.I.D. temperature controller with over-temperature deviation protection and digital display is adopted, with timing function, and the temperature control is accurate and reliable.

★ The upgraded version of the sound and light alarm environment scanning microcomputer chip has more powerful data processing functions

★ Functions such as over-temperature alarm, timed shutdown, call recovery, parameter encryption, temperature correction and so on.

★ With the function of power-off recovery, the equipment can automatically resume operation according to the original program after the external power supply suddenly loses power and the power comes again

Security settings

★ Thoughtful safety protection design realizes triple safety protection for personnel, samples and equipment

★ Safety functions: sensor fault alarm, over-temperature alarm, independent over-rise preventer, independent over-temperature protector, over-current trip protection, etc

Product display

JieCheng DHG-9078A High temperature Forced Air Drying OvenSpecifications

| LIST | VALUE |

|---|---|

| Temperature range | 100~500℃ |

| Temperature Fluctuation | ±0.1℃ |

| Temperature Resolution | 0.1℃ |

| Volume | 70L |

| Interior size | 400*400*450mm |

| Chamber material | 304 stainless steel |

| Shelf (std.) | 2pcs |

| Timer | 1~9999min |

| Power supply Voltage | AC 220V 50Hz |

| Input Power | 1200W |

| Environmental temperature | RT+5~40℃ |

| Dimensions | 840*620*675mm |

| Display mode | Digital one-screen display |

| Door opening method | Open the door manually |

| Viewing Window | without |

JieCheng DHG-9078A High temperature Forced Air Drying Oven Packing list

integrated host x1, power cord x1, manual x1, certificate x1, warranty card x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Preparation method and step of film

- GB 1727 film general preparation method

- Coated Film thickness performance analysis

- Coating film formation performance inspection method--paint (coating) film preparation

- Shanghai Jiecheng full series of box selection reference table [selection]

- Design and Application of Metering rod Spreader

- How to prepare a test sample - Method for preparing a sample sample

- ISO 8130-11:1997 - Determination of fluidity of inclined plates - Introduction

- How is film thickness measured?

- Coating film formation performance inspection method - film preparation

- ActiveGB/T 30435-2013

- ActiveJB/T 5520-1991

- ActiveGB/T 11026.5-2010

- ActiveGB/T 21782.7-2008

- ActiveGB/T 16777-2008

- AbolishGB/T 16592-1996

- ActiveGB/T 6753.3-1986

- ActiveGB/T 1979-1979

- ReplacedGB 1727-1992

DHG-9078A

DHG-9078A