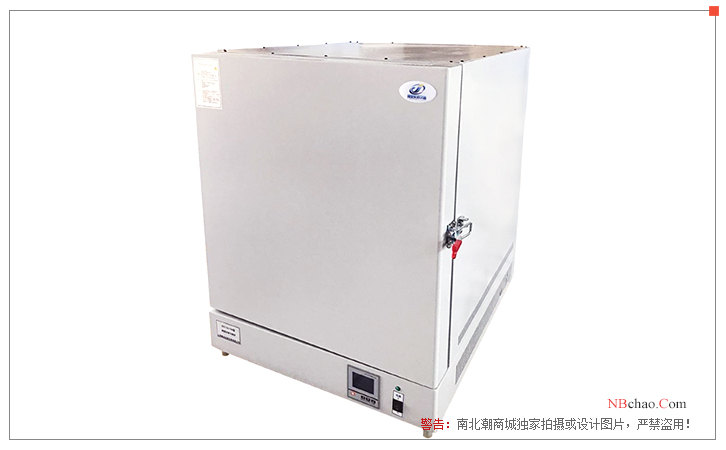

JIECHENG SX2-16-12A Laboratory muffle furnace volume 80L temperature control: room temperature + 50~1200 ℃

JIECHENG SX2-16-12A laboratory muffle furnace adopts ceramic fiber liner, volume is 80L, SX2-16-12A laboratory muffle furnace can be equipped with optional programming controller, input Power is 16KW, with 400 * 500 * 400mm liner size.

JieCheng

JieCheng-

BOZHEN BZ-12-10P program temperature control muffle furnace 30 program PID temperature control

$ 893.00 -

BENTING CSX2-12-10 experimental Box-Type Resistance Furnace 1000 ℃/30L

Login -

JINGQI SX2 - 2.5-12 Tp ceramic fiber muffle furnace 1200 ℃

$ 1313.00 -

HUITAI 1.5-12 T ceramic fiber muffle furnace temperature 1200 ℃ volume 1.9L

Login -

BOZHEN BZ- 2.5-12 muffle furnace 1200 ℃ high temperature Box-Type Resistance Furnace

$ 435.00

Introduction

Ceramic fiber muffle furnace is a periodic operation electric furnace, which can be used for chemical analysis, physical determination and heating of general small steel parts in the laboratories of industrial and mining enterprises and scientific research units. Jiecheng SX2-16-12A laboratory muffle furnace adopts ceramic fiber liner, with a volume of 80L and a temperature control range of room temperature +50~1200°C.

Features

1. The inner tank is made of ceramic fiber, the equipment is lightweight, and the insulation effect is good.

2. Intelligent LCD controller, good temperature control effect; A large number of exports to European countries

3. LCD one-screen display, temperature, time and other parameters

4.Streamlined luxury machine shape with aesthetic design concept, electrostatic spraying box

5.The furnace body is made of ceramic fiber material, which has the characteristics of good thermal insulation performance and light weight, and the insulation layer is insulated by ceramic fiber cotton, which greatly improves the heating rate, reduces the heat consumption, has good thermal insulation effect, and has low shell temperature.

6.The large LED LCD screen displays the set parameters and measured parameters

7.The heating temperature of the ceramic fiber muffle furnace is uniform, the heating speed is fast, the energy saving performance is good, and the dust and slag will not affect the effect of the test.

Introduction to controls

★ The microcomputer P.I.D. temperature controller with over-temperature deviation protection and digital display is adopted, with timing function, and the temperature control is accurate and reliable.

★ The upgraded version of the sound and light alarm environment scanning microcomputer chip has more powerful data processing functions

★ Functions such as over-temperature alarm, timed shutdown, call recovery, parameter encryption, temperature correction and so on.

★ With the function of power-off recovery, the equipment can automatically resume operation according to the original program after the external power supply suddenly loses power and the power comes again

Security settings

★ Thoughtful safety protection design realizes triple safety protection for personnel, samples and equipment

★ Safety functions: sensor fault alarm, over-temperature alarm, independent over-rise preventer, independent over-temperature protector, over-current trip protection, etc

Display diagram

JieCheng SX2-16-12A Box FurnaceSpecifications

| LIST | VALUE |

|---|---|

| Furnace Volume | 80L |

| Heating power | 2.5KW |

| Furnace size | 400*500*400mm |

| Power supply Voltage | 380V 50Hz |

| Dimension | 480*480*590mm |

| Display mode | LCD liquid crystal word display |

| Temperature Resolution | 1℃ |

| Temperature range | RT+50~1200℃ |

| Temperature Fluctuation | ±2℃ |

| Environmental temperature | 5~40℃ |

| Timer Range | 1~9999min |

| Door opening method | Open the door manually |

JieCheng SX2-16-12A Box Furnace Packing list

integrated host x1, power cord x1, manual x1, certificate x1, warranty card x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Development of PPESK High Temperature Self-Lubricating Wear-resistant Coatings

- Process Analysis of Simultaneous Thermal Operation of Various Specifications of Steel Wire in Furnace

- Development and analysis of fire-proof coatings for boron-containing ultra-thin steel structures

- Water-based Infrared-Laser Composite Stealth Coatings

- Discussion on improvement scheme of steel wire heat treatment muffle furnace

- Research and Analysis on Determination of Ash in Tobacco by Microwave Furnace Experiment

- How to use muffle furnace program temperature control to determine tea ash content?

- Formulation design and prepative of epoxy silicone high-temperature coatings

- Linear dispersion of furnace heating

- The calibrating of box resistance furnace for experiment

SX2-16-12A

SX2-16-12A