FLUKO FM30-D High shear dispersion Mulser digital display Processing capacity 200~10000ml

FLUKO FM30-D High Shear Dispersion Mulser is suitable for medium batch and medium viscosity materials for dispersion emulsification. FM30-D High Shear Dispersion Mulser adopts double stator structure design to achieve stepless speed regulation and digital display Rotation speed.

fluko

fluko-

RONGHUA RHJZQ-10JM Pat Aseptic Homogenizer with heat sterilizer

$ 1161.00 -

Lanyu 12G Homogenizer can be equipped with optional dispersion head

$ 324.00 -

Lanyu LYD500W-T LABOratory High Shear Dispersion Homogenizer 30G/100-8000ml

$ 1033.00 -

Huxi HX-4GM beat homogenizer, upgraded model

$ 1161.00 -

Lanyu LYD500W-T LABOratory High Shear Dispersion Homogenizer 12G/30~800ml

$ 855.00

Introduction

Fluke FM30-D high shear dispersion emulsifier continuously variable speed, high-precision digital display, strong torque output. Double stator structure to multiply the shear effect; Equipped with various forms of stator, which can be used interchangeably according to process requirements; Double security.

Applicable process

FM30-D batch high shear dispersion emulsifier is suitable for medium and medium viscosity materials, as well as the dispersion, emulsification, homogenization and mixing of solid-containing liquids.

Application

It is suitable for biological, food, daily chemical, chemical, new materials, aerospace, military and other industries.

Presentation diagram

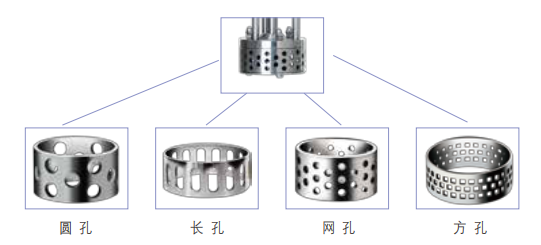

Stator form

fluko FM30-D FLUKO High Shear Dispersion MulserSpecifications

| LIST | VALUE |

|---|---|

| Power | 300W |

| Power Supply | 220V,50Hz |

| Processing Capacity | 200~10000ml |

| Max. Processing Viscosity | 5000CP |

| Speed range | 300~11000rpm |

| Rotation speed display | digital display |

| Rotation speed control | stepless speed regulation |

| Contact material | SS304 |

| Bushing material | Copper alloy |

| Environmental temperature | 5~40℃ |

| Allowable Relative Humidity | ≤80% |

| Process type | batch processing |

| Work frame, base | Standard |

| Dimension | 360*260*760mm |

| Weight | ~10kg |

| Encasement | carton |

| stator form | Round hole, long hole, mesh, square hole |

fluko FM30-D FLUKO High Shear Dispersion Mulser Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Difference Between High Shear and Low Shear Stirring Dispersion

- Three properties of ink leading to emulsification

- What is ink emulsification? Features of emulsion

- Is the higher the Mulser speed the better?

- Working principle and classification of high shear Mulser

- An Effective Method to Disperse Pigments

FM30-D

FM30-D