FLUKO FM300 Intermittent High Shear Dispersion Mulser Processing capacity 200~10000ml

FM300 High Shear Dispersion Mulser is a batch high shear dispersion Mulser produced by FLUKO. The scale shows the Rotation speed. The FM300 Speed range is 300-11000rpm. The FM300 High Shear Dispersion Mulser is suitable for medium batch, medium viscosity materials, high temperature Operating Conditions and other fields.

fluko

fluko-

Huxi HX-4GM beat homogenizer, upgraded model

$ 1161.00 -

Lanyu 12G Homogenizer can be equipped with optional dispersion head

$ 324.00 -

Huxi FJ200-SH Digital Display Constant Speed High Speed Dispersion Homogenizer Φ12/18mm

$ 585.00 -

HUXI HX-4 Tapping Homogenizer, Upgraded

$ 940.00 -

RONGHUA RHJZQ-10M Pat Aseptic Homogenizer with sterilizer

$ 972.00

Introduction

Fluke FM300 batch high shear dispersing emulsifier adopts high-performance motor and strong torque output, which can be competent for laboratory dispersion, emulsification, homogenization and other functions. Accurate speed display and double safety protection; Equipped with three different stators, they can be used interchangeably according to process requirements.

Applicable process

FM300 batch high shear dispersing emulsifier is suitable for small batches, medium viscosity materials, high temperature conditions, as well as dispersion, emulsification, homogenization and mixing of solid-containing liquids.

Application

It is suitable for daily chemical, chemical, new materials, aerospace, military and other industries.

Presentation diagram

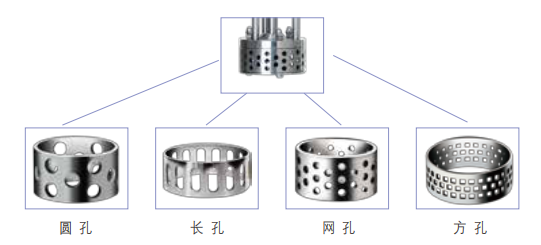

Stator form

fluko FM300 FLUKO High Shear Dispersion MulserSpecifications

| LIST | VALUE |

|---|---|

| Power | 300W |

| Power Supply | 220V,50Hz |

| Processing Capacity | 200~10000ml |

| Max. Processing Viscosity | 5000CP |

| Speed range | 300~11000rpm |

| Rotation speed display | scale |

| Rotation speed control | stepless speed regulation |

| Contact material | SS304 |

| Bushing material | Copper alloy |

| Environmental temperature | 5~40℃ |

| Allowable Relative Humidity | ≤80% |

| Process type | batch processing |

| Work frame, base | Standard |

| Dimension | 210*290*675mm |

| Weight | ~13kg |

| Encasement | carton |

| stator form | Round hole, long hole, mesh, square hole |

| Independent governor standard | Standard |

fluko FM300 FLUKO High Shear Dispersion Mulser Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Difference Between High Shear and Low Shear Stirring Dispersion

- Three properties of ink leading to emulsification

- What is ink emulsification? Features of emulsion

- Is the higher the Mulser speed the better?

- Working principle and classification of high shear Mulser

- An Effective Method to Disperse Pigments

FM300

FM300