Furnace temperature tracker TC-60K DAQTECH six test channels, electronic, painting, tunnel furnace temperature test

DAQTECH TC-60K Furnace temperature tracker is a tunnel furnace temperature Tester, TC-60K is a six-channel furnace temperature Tester, TC-60K oven temperature tracker continuously tests 256 groups of temperature Linear dispersion.

DAQTECH

DAQTECH-

Rennes LN-80K Semiconductor curing Furnace temperature tracker 8 channels 200 ℃ 1 hour

$ 2424.00 -

Rennes LN-60K aluminum brazing special Furnace temperature tracker 6 channels 700 ℃ 1 hour

$ 4204.00 -

TQC CX2030 Probe Connector CX2030 Clamp Workpiece Surface Thermocouple

$ 467.00 -

Rennes HC-4 painting Furnace temperature tracker 4 channels 300 ℃ 1 hour

$ 787.00 -

Rennes LN-60K painting Furnace temperature tracker 6 channels 300 ℃ 1 hour

$ 1423.00

Introduction

Dafengke TC-60K furnace temperature tracker is a six-channel tunnel furnace temperature Tester, which uses K-type thermocouples, can continuously test 256 sets of temperature curves and can divide 15 temperature zone segments. TC-60K furnace temperature tracker provides accurate furnace temperature curve test, with professional analysis software, according to the measured wave soldering and reflow soldering furnace temperature curve test, it can provide accurate judgment and optimization for process indicators, and can realize solder paste information and equipment information , Product information management and editing horizontal temperature line and time point line. The temperature measurement range of TC-60K furnace temperature tracker is -100~1200℃.

Applications

TC-60K furnace temperature tracker is widely used in the temperature consideration of SMT placement and plug-in PCB welding process in the electronics industry, and can also be used for temperature mapping and analysis in food, environment, coating, oven, tunnel furnace and other industries.

Temperature curve analysis setting function

1. Add process index (PWI) analysis

2. Increase solder paste information management

3. Increase equipment information management

4. Increase product information management

5. The horizontal temperature line and time point line can be moved and edited

6. The data will not be lost when the instrument is powered off

7. The Recorder can continuously record 256 groups of temperature data, and download them in one group.

8. Set the temperature and transportation speed in the temperature zone of the reflow furnace and the wave peak furnace

9. Location name of temperature sampling point and schematic diagram of PCB

10. Time between two temperature values

11. The slope between two temperature values

12. The slope between two time points

13. The time beyond the specified temperature

14. Maximum temperature and temperature at any point in time

15. Horizontal temperature line, vertical time line and the time between the two times

16. Mesh editing refinement and curve zoom display

17. Simulation curve function, process optimization, test date and time

18. Input of company name, product name and remarks

19. Select the printing direction (landscape printing and portrait printing)

20. The temperature data report can be exported to Excel for editing

21. The function of inserting pictures makes the position of the temperature test point clear at a glance

22. Call multiple sets of temperature curves for comparison

23. Two Operating Modes of real-time monitoring and instrument recording

24. Manually clear and software clear instrument memory data methods

25. Three starting modes: manual, specified time, and specified temperature

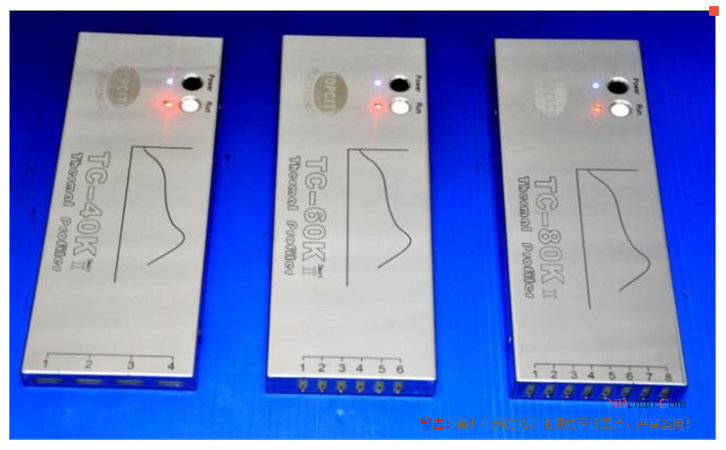

Pictures

DAQTECH TC-60K Furnace temperature trackerSpecifications

| LIST | VALUE |

|---|---|

| Number of channels | 6 |

| Probe Type | K type |

| temperature Measurement Range | -100~1200℃ |

| temperature measurement Accuracy | ±1℃ |

| Sampling interval | 0.05-600 seconds, software settings |

| resolution | 0.1 ℃ (full scale) |

| Storage Capacity | 120,000 points/channel |

| Total power | ≤100mW |

| Power | 3.6V (built-in rechargeable battery) |

| Connectivity | RS-232 or USB (optional) |

| Recorder size | 208*75*20mm |

| Insulation box size | 252*88*30mm |

| wingspan width | 98-218mm (std.) |

| Analysis software | e-DataPro Chinese and English three languages |

DAQTECH TC-60K Furnace temperature tracker Packing list

Host x1, instrument protection box x1, Thermocouple x6, software installation disc x1, data output line x1, high temperature adhesive paper x1, charger x1, instrument box x1, scissor x1, forceps x1, thermal insulation gloves x1, cross screwdriver x1, high temperature tin wire x1, user manual x1, certificate x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.