German EPK MiniTest 4100 microcomputer precision platings Thickness Gauge host, without probe

EPK MiniTest 4100 precision coating platings Thickness Gauge is MiniTest microcomputer precision coating platings Thickness Gauge, can be divided into 99 groups, a total of 10,000 measurement data storage, Mintest4100 precision coating platings Thickness Gauge has powerful data processing function, can set the limit value.

ElektroPhysik

ElektroPhysik-

German EPK MiniTest 735 N0.7 eddy Current Thickness Gauge, Thickness 0~700μm

Login -

LEEB Probe N1 eddy Current Probe with leeb242 Coating Thickness Gauge

Login -

IPRE CT150 Coating Thickness Gauge Measurement range 0~1500μm

$ 238.00 -

YIBAI CTG-802-3000FNV split iron and aluminum dual-use standard large V-shaped Coating Thickness Gauge

$ 269.00 -

Germany EPK MikroTest S5 McCourt coated platings Thickness Gauge, thickness measurement: 0.5~ 5mm

$ 1047.00

Introduction

The German EPK MiniTest Precision Coating Thickness Gauge is used to measure the following cladding (cladding includes coatings, coatings, etc.):

● Non-magnetic cladding on steel substrates (e.g. paint, zinc);

● Insulating cladding on non-ferrous metals (e.g. paint, anodized film);

● Non-ferrous metal cladding on the insulating substrate.

The Mintest Coated Thickness Gauge contains: Minitest 4100、 Minitest 3100、 Minitest 2100、 Minitest The 1100 has four different hosts, each with different data processing capabilities. All probes can be used with either host unit. Factors such as cladding thickness, substrate material, substrate shape, thickness, size, geometry and other factors should be considered when selecting the most suitable probe.

The MiniTest 4100 host can store up to 10,000 measured values in 99 application rows, each of which can be divided into 98 groups. The memory function is useful if different measuring tasks require frequent probe changes for different calibrations. Different calibration and probe parameters can be stored separately and can be recalled at any time. Measurement data can be evaluated and analysed in a variety of statistical ways. Setting limit values allows the operation to be used to monitor tolerances that occur during the production process while taking measurements.

Product Applications

EPK MiniTest 4100 precision coating Thickness Gauge is widely used in automotive, shipbuilding, aviation and machinery manufacturing industries, first-class government inspection agencies and electroplating industries.

Features

1. It can be equipped with all probes(sold separately)

2. It can be connected to MinPrint and PC through RS-232 interface (sold separately)

3. It can be calibrated with 1 or 2 standard foils

Display diagram

Comparison of the features of Minitest 4100-3100-2100-1100 series hosts

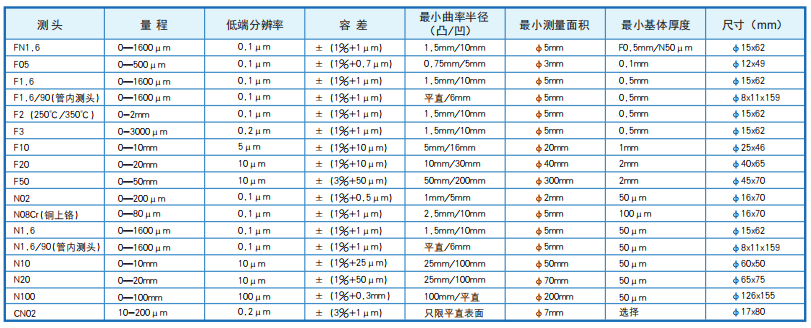

Probes are optional

ElektroPhysik MiniTest 4100 Coated platings Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction + eddy Current |

| Measurement range | Determined by the probe |

| margin of error | Depending on the probe |

| Minimum measurement surface | Depending on the probe |

| Minimum radius of curvature | Depending on the probe |

| thinnest substrate | Depending on the probe |

| probe | Line probe |

| Calibrated Certificate | none |

| Unit display | μm |

| statistical function | none |

| Interface | RS-232 |

| Data storage | 10,000 Measured values |

| Power Supply | 1 * 9V alkaline battery, AC adapter |

| Standards | DIN 50981、DIN 50982、DIN 50984、ISO 2178、ISO 2360、BS 5411、ASTM B499、ASTMB244-CE |

| Display screen | LCD screen |

| Operating temperature | 0~50℃ |

| Battery life | 10,000 measurements |

| Weight | 270g |

| Dimension | 150*82*35mm |

| number of rows applied | 99 |

| Number of groups per application line | 98 |

| Groupable number in memory | most |

ElektroPhysik MiniTest 4100 Coated platings Thickness Gauge Packing list

Host × 1, 9V battery × 1, instruction manual CD, manufacturer's certificate, plastic suitcase.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Coating Thickness Gauge Measurement principle analysis of variable magnetoresistance method

- Introduction of Several New Coating Thickness Gauges and Coating Holiday Detectors

- What is the principle of coating Thickness Gauge?

- Key points for maintenance of coating Thickness Gauge

- How to choose a portable Thickness Gauge?

- Coating Testing Instruments Popular Products Atlas

- Improvement of Coated Film thickness measurement

- ActiveQJ 990.3A-2011

- ActiveASTM B244-2021

- ActiveISO 2360-2017

- ActiveISO 2178-2016

- ActiveASTM D7091-2022

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- AbolishJJG 818-1993

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveHG/T 3885-2006

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- ActiveGB/T 5209-1985

- AbolishASTM G12-07-2013

- AbolishISO 2808-2007

- ActiveJB/T 7663.2-2007

MiniTest 4100

MiniTest 4100