Leeb210 coated Film Thickness Gauge Eletroplating, chemical industry, shipbuilding, light industry, automobile and other fields

Magnetic induction thickness measurement principle, thickness measurement range 0~1250μm, accuracy ± 3%, with single and continuous measurement, support a variety of calibrating methods, no supporting software.

Leeb

Leeb-

YIBAI CTG-802-3000FNV split iron and aluminum dual-use standard large V-shaped Coating Thickness Gauge

$ 269.00 -

Defelsko PosiTector 6000 FT1 Portable platings Thickness Gauge, integrated magnetic Thickness Gauge

$ 1000.00 -

AMITTARI 10m Bluetooth adapter provides Bluetooth data output selection for most AMITTARI series instruments

$ 119.00 -

Defelsko PosiTector 6000 FKS1 Coating Thickness Gauge for coatings

$ 1186.00 -

LEEB leeb252 Coating Thickness Gauge magnetic Induction/eddy Current dual-use automatic identification substrate

Login

Introduction

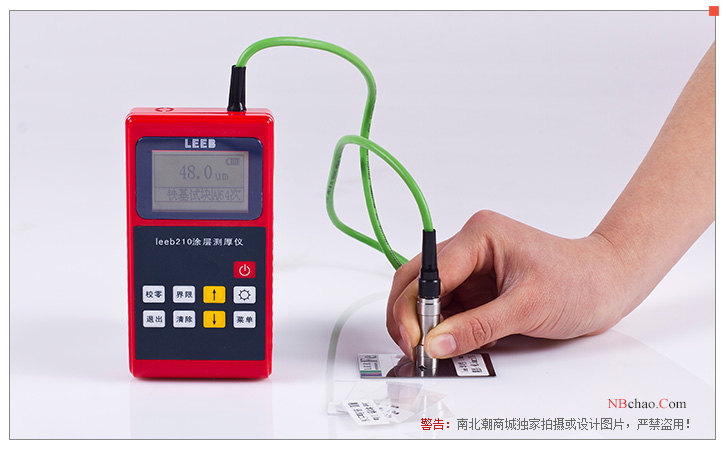

Leeb leeb210 coating Thickness Gauge is a non-destructive testing instrument for measuring coating thickness. It adopts the principle of magnetic induction thickness measurement. The measured film thickness ranges from 0 to 1250 microns. It has two measurement methods: single measurement and continuous measurement, and supports multiple calibrations. Way.

Leeb210 Coating Thickness Gauge can non-destructively detect the thickness of non-magnetic coatings on magnetic metal substrates ( such as chromium , aluminum, copper, tin, zinc , paint, rubber, etc. on iron, steel, alloys and hard magnetic steels ) .

Features

1) Two Operating Modes: direct mode and group mode conversion.

2) Display the last reading after power on.

3) Leeb210 coating Thickness Gauge has the function of measuring data storage.

4) Two measurement methods: single measurement and continuous measurement (quickly obtain readings in a large area) conversion between metric and imperial.

5) All Chinese operation interface, menu interface.

6) With manual and automatic shutdown functions.

7) Various calibration methods, with measurement data storage function.

8) It has the function of deleting measurement data (delete the current measurement value, delete the measurement data of the current group, delete all the data of the current group).

Applications

Leeb210 coating Thickness Gauge can be widely used in chemical industry, light industry, electroplating, anti-corrosion, automobile, shipbuilding, aerospace, aviation, commodity inspection and other testing fields. It is suitable for laboratories and engineering sites, and is a required instrument for the non-destructive testing industry.

Pictures

Leeb Lib 210 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | magnetic induction |

| Measuring range | 0 ~ 1250µm |

| margin of error | ±3% |

| resolution | 0.1µm |

| Minimum measurement surface | F7mm |

| Minimum radius of curvature | Convex 1.5mm |

| thinnest matrix | 0.5mm |

| probe | F1 Split Probe |

| icon function | without |

| Power | 2 * AAA alkalinity battery |

| Calibrated Certificate | without |

| Language | Chinese |

| Display screen | LCD |

| supporting software | without |

| Total Weight | 152g |

| Complete-built unit size | 115*70*30mm |

| Operating Temperature | 0~40℃ |

| Relative Humidity | 20~90%RH |

Leeb Lib 210 Coating Thickness Gauge Packing list

Host x1, Certificate x1, Manual x1, Encasement box x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle and Application Analysis of Coating Thickness Gauge

- Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveGB/T 42541-2023

- ActiveGB/T 7991.5-2014

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveISO 2178-2016

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- AbolishASTM G12-07-2013

- ActiveJB/T 7663.2-2007

Lib 210

Lib 210