REDDRAGON TC-200 Coating Thickness Gauge dual-use Film thickness meter Measurement range 0~1300μm

Magnetic eddy current dual-use; thickness measurement up to 1300μm, +/- 3% thickness measurement accuracy, built-in probe, support single point measurement/continuous Measurement mode.

Reddragon

Reddragon-

Defelsko PosiTest DFT Combo Coating Thickness Gauge for measurement of coarse or cylindrical surface coatings

$ 823.00 -

YIBAI CTG-600F10 Single iron Coating Thickness Gauge 10mm

$ 350.00 -

LANDTEK CM-1210-200F Coating Thickness Gauge

$ 577.00 -

Defelsko FT Detachable built-in probe

$ 703.00 -

AMITTARI AC-112-200F Coating Thickness Gauge Iron-based film thickness Measurement Instrument

$ 620.00

Introduction

This Thickness Gauge is used to measure the thickness of electroplating or coating on metal surfaces, specifically the thickness of non-magnetic coatings on the surface of magnetic materials such as steel/iron (such as chromium/paint/ceramics, etc.), and the thickness of the coating on the surface of non-magnetic materials such as copper/aluminum (such as paint, etc.). The instrument has a built-in precision probe that automatically detects substrate properties and detects coating thickness through electromagnetic induction and eddy current effects.

Product Applications

This instrument can measure the thickness of coating and plating without damage, quickly and accurately. It is widely used in manufacturing, metal processing industry, chemical industry, commodity inspection and other testing fields, and is an instrument required for material surface treatment engineering. It can work stably in the laboratory, workshop site and outdoors.

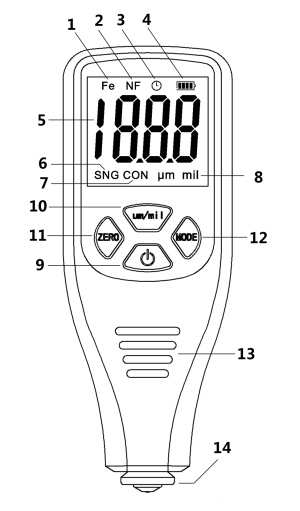

Feature description

1. Fe indicates that the substrate to be measured is a magnetic material: steel/iron, etc

2. NF indicates that the substrate to be measured is a non-magnetic material: copper/aluminum, etc

3. Automatic shutdown logo, the machine will automatically shut down without operation for 5 minutes

4. Battery level indicator

5. Measurement reading display

6. The SNG indicates that it is currently a single point measurement mode

7. The CON indication is currently in fast continuous measurement mode

8. Numerical units: um is micron, mil is the American customary unit mil

9. Power on and off button

10. UM/MIL key, function 1: unit switching, function 2: press and hold for more than 3 seconds, the machine will be restored to factory settings

11. ZERO button, SNG display (single point mode) is: clear the screen; When the CON is displayed (fast continuous mode), it is: calibration key

12. MODE button, switch mode SNG/CON, SNG display is single point mode, CON display is fast continuous mode

13. Anti-slip groove, convenient for thumb and index finger to pinch the machine during measurement

14. Measure the probe

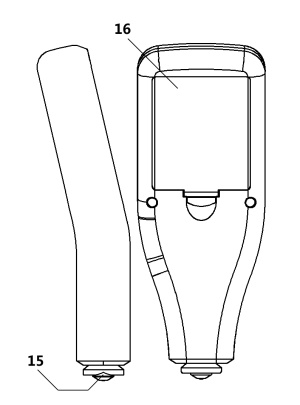

15. V-groove, which is used to measure convex surfaces, such as the surface of steel pipes

16. Remove the battery cover of the machine and install 4 No. 7 batteries

Presentation diagram

Reddragon TC-200 Black Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction + eddy Current |

| Measurement range | 0~1300μm |

| margin of error | ±3% |

| resolution | 0.1μm |

| Minimum measurement surface | Fe probe (iron base): 0.5mm, NF probe: 0.3mm |

| minimum radius of curvature | Convex 1.5mm; Concave 25mm |

| thinnest matrix | 0.5mm(F);0.3mm(N) |

| probe | F & NF integrated probe |

| Calibrated mode | Zero calibrated; multi-point calibrated; |

| statistical function | Induction of magnetic and eddy current measurements |

| Unit display | μm/mils |

| Power Supply | 4 * 1.5V AAA battery |

| Operating temperature | 0~40℃ |

| Relative Humidity | 20~90%RH |

| Operating temperature | No strong magnetic field |

| Weight | 125g |

| Dimension | 155*62*35mm |

Reddragon TC-200 Black Coating Thickness Gauge Packing list

Host X1, tool case X1, manual X1, iron substrate X1, aluminum substrate X1, thickness standard sheet X1, product instruction manual X1, 4 No. 7 alkaline batteries X1, product certificate X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Introduction of nondestructive thickness testing principle and instrument

- Measuring methods of coating Thickness Gauge

- Choice of Coatings

- Principle characteristics and application of silver Film Thickness Gauge

- How to choose a suitable painting Thickness Gauge?

- Coating Thickness Gauge Measurement principle analysis of variable magnetoresistance method

- Why Use Coating Thickness Gauges in Powder Coatings?

- Coating Thickness Gauge Measurement principle analysis of ultrasonic pulse echo method

- This article lets you master the determination of Film thickness

- Application of Coating Thickness Gauge on Galvanized Steel Sheet

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveHG/T 5367.1-2018

- ActiveASTM B244-2021

- ActiveISO 2360-2017

- ActiveISO 2178-2016

- ActiveASTM D7091-2022

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ActiveGB/T 1740-2007

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- AbolishJJG 818-1993

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveHG/T 3885-2006

- ActiveGB/T 12334-2001

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

TC-200 Black

TC-200 Black