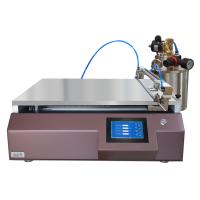

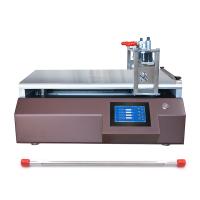

TQC AB4405 Automatic Film Applicator Perforated heating vacuum Table 115V

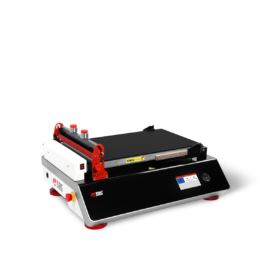

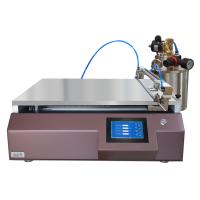

AB4420 Bedless Combo | Automated thin film Coating Applicator with vacuum and fixture is a universal thin film Coating Applicator. Suitable for any type of substrate, capable of handling the most difficult tasks.

TQC sheen

TQC sheen-

HuiNuo TM3300Pro/32D Floor-to-ceiling drawdown Bar & Blade Vacuum chuck Coater 150 * 30cm

Login -

China TBJ-X1-DJ2 Experimental Drawdown blade Coater automatic feeding + Vacuum chuck + Drawdown blade Multifunctional Film Applicator

$ 5124.00 -

HuiNuo TM3100/02 drawdown Bar & blade heating Coater Spreader, width 300 * 700mm

$ 5597.00 -

China TBJ-X3-DJ5 drawdown Bar & blade heating Vacuum chuck Film Applicator with automatic feeding system

$ 7334.00 -

HuiNuo TM3000Pro/28 Automatic Film Applicator ECA 800 * 500mm servo motor

$ 4492.00

The TQC Automatic Film Applicator provides a reliable basis for applying the coating film to test cardboards, panels or foils in an even and repeatable manner to eliminate variations caused by the human factor.

Advantages:

More space for coating and scrubbing

Compatible with a wider range of coating application tools

Drying time recording is optional

The preset range is optional

Easy and intuitive operating space (smart lighting interface)

Paper clips/vacuums can be operated manually

Full-color LCD screen

Easy-to-update software

AB4120 Standard:Glass bed |

AB4220 Standard: Perforated vacuum Table |

AB4320 Standard:Two-channel vacuum Table |

AB4420 Empty aircraft, but cancombinationAdaptation |

AB4400 Standard:Perforated heated vacuum Table - 230VAC |

AB4405 Perforated heated vacuum Table - 115VAC |

Features

Repeatable

Changes in speed, pressure, and drafting direction can cause irregularities. Other factors that may affect the results are the shear rate and the weight of the applicator. With an automated Film Applicator, these variables are stabilizing. The thickness of the film is uniform over the entire surface. Samples created using an automated Film Applicator are reproducible. A large number of the same laboratory precision can be produced in a short period of time.

Rheological properties

The quality of the applied film is important to study the rheological properties of the applied medium. In order to prepare samples for testing rheological properties, abrasion resistance, hiding power, and gloss, an automated Film Applicator is required. Several types of automated Film Applicators are available for glass/paper/metal substrates or foils.

Applicators and wire rods

Depending on the selected configuration, all models can be combined with a standard block Film Applicator (e.g. Bird/Baker type) or a spiral rod Film Applicator (winding rod type).

Unique interface

Each automatic Film Applicator 'standard' is equipped with the TripleI® navigation tool. Triple I stands for Smart Lighting Interface. This unique navigation tool guides the operator through the interface of the TQC Sheen laboratory machine. At each step of the action menu, the interface detects which buttons are active and indicates them with a bright red center. The result is a very intuitive operating system that is enhanced by information on the machine's display.

Heated bed

The automatic Film Applicator comes standard with a porous heated vacuum Table with a built-in heating pad that raises the table temperature to +100°C above ambient temperature. The powerful heating unit ensures an even temperature distribution throughout the vacuum plate. Set and control the temperature with the TripleI® navigation tool

Optional

TQC sheen AB4405 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Coating speed | 0.1~500mm/s |

| Conductor speed Accuracy | ±1% |

| Spreader trip | 50~415mm |

| Precision of stroke length | ±2mm |

| Maximum film area | 515*300mm |

| Maximum test cardboard thickness | 9mm |

| Maximum test substrate thickness | 35mm |

| Vacuum Area | DIN A3 / Scrub |

| Vacuum Area | DIN A5, DIN A4, DIN A3, Scrub |

| Application width | ≤325mm |

| Minimum length of coating rod | 345mm |

| Maximum diameter of coating rod | Φ10mm |

| Miscellaneous film applicator width | ≤300mm |

| Miscellaneous film applicator height | 10~80mm |

| Applicable standards | ASTM D823 |

| Dimensions | 490*640*290mm |

| Machine Weight | 33Kg |

| Host Power Supply | 100~240VAC/50~60Hz |

| energy consumption | ≤50W |

| Display | 480 * 272 pixel TFT display |

| language | English, Spanish, Chinese, Polish, German, French, Italian, Japanese, Russian, Turkish |

| Control mode | 5-Key navigation switch, mouse and keyboard optional |

| Standard | Perforated heating vacuum bed 115V |

| Coating method | Wire rod/drawdown blade |

TQC sheen AB4405 Automatic Film Applicator Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Barrier film primer after UV bonding coating solution [Coating machine case]

- Application and Development Trend of Plasticizers in Coating Industry

- Application of Experimental Automatic Film Applicator in photoresist film prepative

- Application and optimization of Automatic Film Applicator in preparation of eye patch

AB4405

AB4405