Magnetic Coating Thickness Gauge HC-210 Hypertherm digital magnetic Coating Thickness Gauge F probe

Measurement range 0~1250μm, error range +/- 3%, resolution 0.1μm | 1μm, can accurately and quickly nondestructive measurement of the thickness of platings, portable models, not only for laboratories, but also for engineering sites, widely used.

HBO

HBO-

German PHYNIX Surfix SX-N0.5A Split Micro Probe Coating Thickness Gauge

$ 2094.00 -

German EPK MiniTest 735 F5 iron-based Thickness Gauge, measuring thickness 0~5000μm

$ 2105.00 -

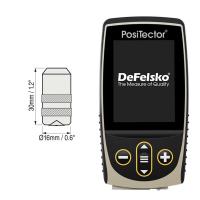

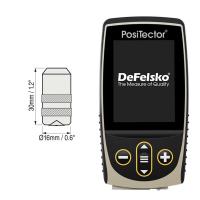

Defelsko PosiTector 6000 FTS3 Coating Thickness Gauge Advanced thick coating probe

$ 1625.00 -

German EPK F 2/90 magnetic right angle probe, thickness measurement range 0~2000um

$ 2067.00 -

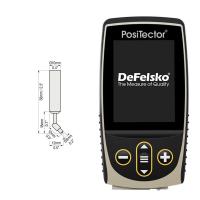

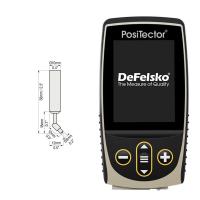

Defelsko PosiTector 6000 N45S3 Coating Thickness Gauge 45 ° micro probe

$ 1818.00

Introduction

The Hypertherm Coating Thickness Gauge HC-210 is a single-function magnetic coating Thickness Gauge with an F-probe that displays test data digitally on an LCD display in both continuous and single-shot measurement methods. The HC-210 Magnetic Coating Thickness Gauge adopts the principle of magnetic thickness measurement, which can accurately and quickly measure the thickness of the coating layer without destructiveness, and is a portable model that can be used not only in the laboratory, but also in the engineering field, and has a wide range of applications.

Product Applications

HCThe -210 Magnetic Coating Thickness Gauge is an instrument needed for material protection and is capable of non-destructively testing the thickness of non-magnetic overlays (e.g., zinc, aluminum, chromium, copper, rubber, paint, etc.) on magnetic metal substrates (e.g., steel, iron, alloys, hard magnetic steels, etc.). It can be widely used in manufacturing, metal processing industry, chemical industry, commodity inspection and other testing fields.

Features and advantages

1. HC-210 Magnetic Coating Thickness Gauge adopts the magnetic thickness measurement method, which can measure the thickness of the non-magnetic covering layer on the magnetic metal matrix;

2. There are two measurement methods: continuous measurement mode and single measurement mode;

3. Two working methods: direct mode and group mode;

4. There are five statistics: average, maximum, minimum, number of tests, and standard deviation;

5. Two methods are used to calibrate together, and the systematic error of the probe can be corrected by the basic calibration method;

6. It has the function of storage: it can store 500 measured values;

7. HC-210 Magnetic Coating Thickness Gauge has the function of power supply underVoltage indication;

8. There is a buzzer prompt in the operation project;

9. With printing function: it can print measured values, statistical values, limits, and histograms;

10. It has the function of deleting: delete the single suspicious data that appears in the measurement, and delete all the data in the storage area in order to carry out new measurements;

11. The limit can be set: the measured value outside the limit can be automatically alarmed; and a histogram can be used to perform Fenix on a batch of measurements;

12. It has the function of communicating with the PC: the measured value and statistical value can be transmitted to the PC for further processing of the data;

13. There are two shutdown modes: manual shutdown mode and automatic shutdown mode.

14. It has the function of error prompt, and the error prompt is carried out by screen display or buzzer;

Instructions

1. Connect wellHC-210 Magnetic Coating Thickness Gaugeprobes;

2. Place the probe in an open space, press the power button, and turn it on;

3. Check the battery Voltage;

4. Under normal conditions when the machine is turned on, the measured value before the last shutdown will be displayed after the power on;

5. Determine whether calibration is requiredHC-210 Magnetic Coating Thickness Gauge, calibrated if required;

6. Measurement: quickly contact the probe perpendicular to the test surface and gently press the probe positioning sleeve, with a sound, the screen displays the measured value, and the probe can be pulled out for the next measurement;

7. Shutdown: without any operation, after about 2~5min,The HC-210 Magnetic Coating Thickness Gauge will automatically power off, press the power button once, and it will power off immediately.

Actual picture of the product

HBO HC-210 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | magnetic Induction |

| Measurement range | 0~1250μm |

| margin of error | ±3% |

| resolution | 0.1μm|1μm |

| Minimum measurement surface | Φ7mm |

| minimum radius of curvature | Convex 1.5mm; Concave 3mm |

| thinnest matrix | 0.5mm |

| probe | F split probe |

| statistical function | Measurement Times, MAX Maximum, MIN Minimum, Average, Standard deviation |

| icon function | without |

| Calibrated Certificate | without |

| system language | Chinese |

| Display screen | Back view, four-digit reading display, two-line statistical display, Chinese operation |

| companion software | without |

| Weight | 200g |

| Dimension | 140*65*30mm |

| Calibrated mode | Manufacturer calibrated, zero calibrated, calibrated foil calibrated |

| Operating temperature | 0~40℃ |

| Relative Humidity | 20~90%RH |

HBO HC-210 Coating Thickness Gauge Packing list

host x1, probe x1, standard piece x5, substrate x1, alkaline battery x2, certificate x1, warranty card x1, manual x1, instrument case x1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveQJ 990.3A-2011

- ActiveISO 2178-2016

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- ActiveJB/T 5000.12-2007

- AbolishGB/T 1764-1979

- ActiveGB/T 13452.2-2008

- ActiveGB/T 11374-2012

HC-210

HC-210