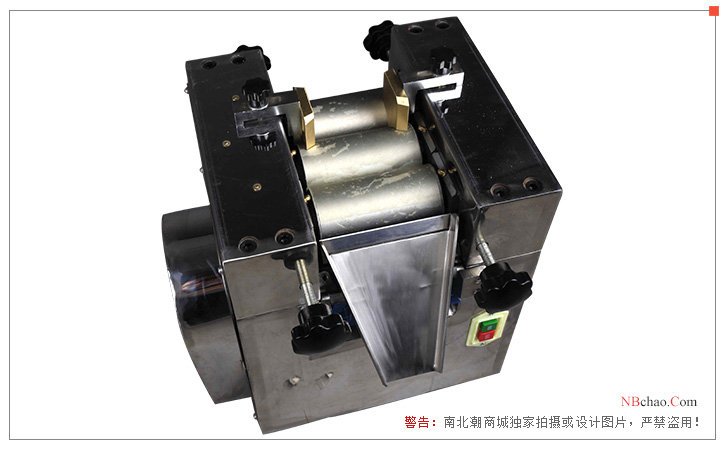

MODERNER Coating Three-roll Grinder XD-20-65/T roll with aluminum oxide material

XD-20-65/T (aluminum oxide) Coating Three-roll Grinder is MODERNER's best-selling small Three-roll Grinder (ie three-roll grinding machine), which has a wide range of applicability. The roller of this XD-20-65/T Coating Three-roll Grinder is made of aluminum oxide.

Moderner

Moderner-

Three-roll grinder S-260 Grinder High viscosity fine grinding dispersion, roller diameter 260mm

$ 7223.00 -

Three-roll grinder S-200 mass production type three-roll machine, paint inks grinding dispersion, roller diameter 200mm

$ 5157.00 -

Small batch three roller grinding Disperser S-150 grinding three roller machine, roller diameter 150mm

$ 2058.00 -

JINGKELIAN QGM-65 Three-roll Grinder with hard chrome plating

$ 867.00 -

Laboratory Three-roll Grinder S-65 Disperse Grinder Roller diameter 65mm

$ 708.00

Overview of paint three-roller Grinder

MODERNERal paint three-roller Grinder XD-20-65/T (alumina) is a laboratory three-roller Grinder that integrates multiple functions such as crushing, dispersion, emulsification, homogenization, and color mixing. XD- The transmission system of the 20-65/T (alumina) coating three-roller Grinder adopts a multi-row chain soft start, which has the advantages of high transmission efficiency, smooth grinding operation, and no noise generation. The roller distance can be adjusted by the parallel handwheel. screw to adjust.

The roller material of this paint three-roller Grinder is made of alumina, which has wide applicability. It is also a popular model among MODERNERal paint three-roller Grinders.

How to operate paint three-roller Grinder

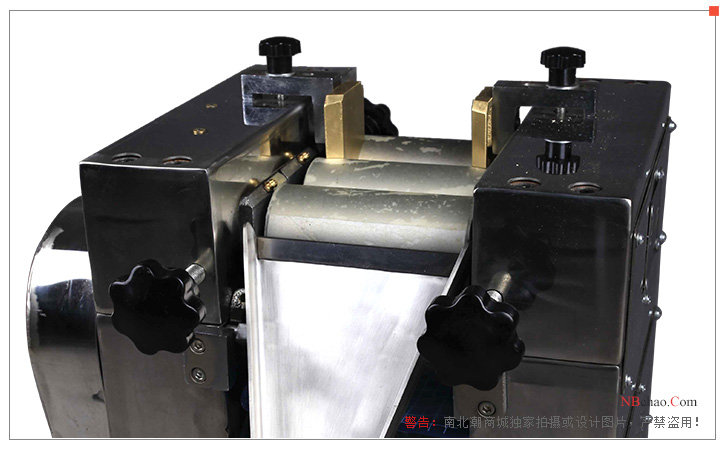

1. After the XD-20-65/T paint three-roller Grinder is started, adjust the gap between the middle roller and the rear roller within the appropriate range as required, and press the baffle plate tightly.

2. Add the laboratory sample to be ground, observe the depth of coloring, slightly adjust the back roller to ensure that the sample can evenly cover the roller, and then lock the fixing nut.

3. At the same time, adjust the handwheel of the front roller so that the front roller slowly contacts the middle roller until the front roller is evenly colored, and then lock the fixing nut.

4. Adjust the angle of the discharge plate so that it can be pressed lightly on the roller surface so that the abrasive material of the sample can be discharged evenly.

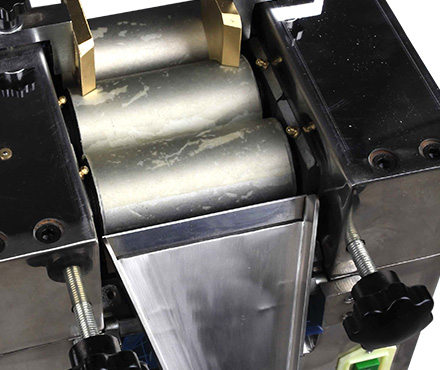

5. Check the uniformity of the discharging material and the particle size of the finished product, and continue to fine-tune the front and rear rollers until the particle size of the ground material reaches the predetermined requirements of the experiment.

6. The scraper of the XD-20-65/T paint three-roller Grinder should be returned in time before and after.

Paint three-roller Grinder display

Moderner XD-20-65/T (aluminum oxide) Grinder (three rolls)Specifications

| LIST | VALUE |

|---|---|

| Motor Power | 0.75KW |

| Dimensions | 410*400*450mm |

| Weight | 60kg |

| Roller material | Aluminum oxide |

| Roller diameter | 65mm |

| Roller working length | 130mm |

| Discharge port height from ground | 220mm |

| Rotation speed | 26rpm |

| Rotation speed of middle roller | 70rpm |

| Rotation speed | 145rpm |

Moderner XD-20-65/T (aluminum oxide) Grinder (three rolls) Packing list

Three-roller machine x1, certificate x1, manual x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

XD-20-65/T (aluminum oxide)

XD-20-65/T (aluminum oxide)