Coating Thickness Gauge AMITTARI AC-112H Special magnetic Induction Coating Thickness Gauge

Magnetic Induction coating thickness measurement, thickness measurement range 0~12000μm, error +/- 3%, suitable for thick coatings such as anti-corrosion coatings thickness measurement, data can be transmitted through USB connection.

AMITTARI

AMITTARI-

Linshang LS225 Coated Thickness Gauge with F500 Magnetic Probe

$ 599.00 -

Defelsko PosiTector 6000 FTS3 Coating Thickness Gauge Advanced thick coating probe

$ 1625.00 -

LINSHANG LS225 Coating Thickness Gauge with N1500 probe + test fixture

$ 886.00 -

Defelsko PosiTector 6000 FRS1 import Thickness Gauge paints/film/film thickness measurement

$ 1058.00 -

AMITTARI 10m Bluetooth adapter provides Bluetooth data output selection for most AMITTARI series instruments

$ 119.00

Introduction

AMITTARI anti-corrosion layer coating Thickness Gauge AC-112H is a portable thickness measuring instrument, which can quickly, without damage, and accurately measure the thickness of coating and coating; it can be used in laboratories and engineering sites; it is widely used It is widely used in manufacturing, metal processing, chemical industry, commodity inspection and other testing fields; it is an instrument required by the material protection profession. AC-112H anti-corrosion layer coating Thickness Gauge adopts the principle of magnetic induction. It complies with the measurement method of international standard ISO2178 and national standard GB4956.

Features

* It can automatically identify the material of the measured substrate.

* There are single and continuous measurement options.

* There is a buzzer sound during operation, but the buzzer does not sound during continuous measurement.

* Use USB data line output to communicate with PC.

* Provide Bluetooth data output option.

* Digital display, wide measuring range and high resolution.

* Automatic memory calibration value, easy to use.

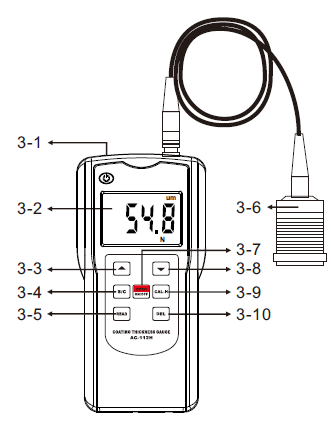

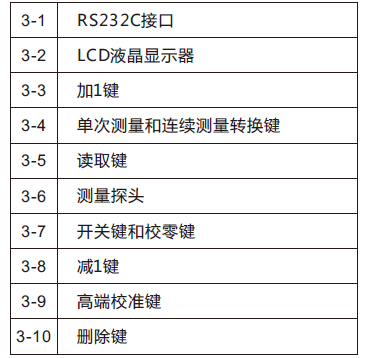

Functional Structure Diagram

Measurement process

1. Since the range of the AC-112H anti-corrosion layer coating Thickness Gauge is greater than 5mm, it is recommended to perform zero calibration professionally before measurement to eliminate measurement errors caused by temperature and humidity changes.

2. Plug in the probe, lightly press the power button, and after turning on the power of the whole machine, the instrument will automatically enter the measurement state and automatically restore the parameter settings before the last shutdown.

3. After confirming that the calibration is correct, the measurement can be started. If there is any doubt about the previous calibration, another . Once the anti-corrosion layer coating Thickness Gauge AC-112H is calibrated, the calibration result will be automatically stored in the AC -112H anti-corrosion layer coating Thickness Gauge , and it is not necessary to calibrate again when starting up for measurement next time, unless the accuracy of the measurement is Have doubts. Press the measuring sensor to the coating to be tested, and the value on the display is the measured value of the coating to be tested. Note that the speed at which the probe presses against the object under test cannot be too slow. Otherwise, it will cause artificial measurement error.

5. For the next measurement, you need to lift the measurement sensor to more than 1 cm, and then repeat 4.

6. If necessary, the measured value can be corrected by plus 1 key or minus 1 key. It should be noted that when pressing the plus 1 key or minus 1 key to correct, the measuring probe must be lifted, otherwise, pressing the plus 1 key or minus 1 key is invalid.

7. AC-112H anti-corrosion layer coating Thickness Gauge needs to change the measurement unit to realize the conversion between mm and mil, just press the unit conversion button lightly.

8. To change the measurement mode and realize the conversion between single measurement and continuous measurement, just press the "S/C" button lightly.

9. After the measurement is completed, lightly press the power button to turn off the power. The AC-112H anti-corrosion layer coating Thickness Gauge has two shutdown modes, namely manual shutdown and automatic shutdown. At any time, just press the power button lightly to turn off the power of the whole machine manually; on the other hand, if no button is pressed within 50 seconds, it will automatically turn off to realize the power saving function .

Pictures

AMITTARI AC-112H Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | magnetic induction |

| Measuring range | 0 ~ 12000μ m |

| margin of error | ±3% |

| resolution | 0.01mm|0.1mm |

| Minimum measurement surface | F36mm |

| Minimum headroom | 90mm |

| thinnest matrix | 0.3mm |

| probe | F Split Probe |

| icon function | without |

| Power | 4 * AAA 1.5V battery |

| Standards | ISO2178、GB4956 |

| Calibrated Certificate | without |

| Language | Chinese |

| Display screen | LCD |

| Data Interface | USB、Bluetooth、RS232C |

| supporting software | Yes (optional) |

| Total Weight | 130G (without battery) |

| Complete-built unit size | 140*70*30mm |

| Unit display | μm/mils |

| Voltage prompt | Low Voltage indication function |

| Operating Temperature | -5~50℃ |

| Optional accessories | USB data cable output, Bluetooth Data output, RS232C communication cable and software |

| Relative Humidity | <95% RH |

AMITTARI AC-112H Coating Thickness Gauge Packing list

Host x1, iron base x1, calibrated diaphragm x1, portable case x1, operation manual x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveISO 2178-2016

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ActiveISO 12944.3-2017

- ActiveISO 12944.2-2017

- ActiveISO 12944.1-2017

- ISO 2361-1982

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- ActiveJB/T 7663.2-2007

- ActiveJB/T 5000.12-2007

- ActiveGB/T 8923.1-2011

AC-112H

AC-112H