TENCAN Powder QXQM-12 Omnidirectional Planetary Ball mill

TENCAN Powder

TENCAN Powder-

DECO Instruments DECO-PBM-V-4L Ultra Bass Heavy Duty Low Shock Planetary Ball mill

$ 1786.00 -

DECO Instruments DECO-PBM-V-6L-A Light Planetary Ball mill

$ 1826.00 -

DECO Instruments DECO-PBM-V-6L Ultra Bass Heavy Duty Low Shock Planetary Ball mill

$ 1897.00 -

DECO Instruments DECO-PBM-V-2/4/6L Subwoofer Heavy Duty Low Shock Planetary Ball mill Vertical

$ 1682.00 -

DECO Instruments DECO-PBM-V-10L Vertical Planetary Ball mill

$ 2543.00

Introduction

The QXQM-12 all-round planetary ball mill is based on the vertical planetary ball mill and adds a planetary disk flip function. While the planetary disk and the ball mill tank are performing planetary motion, they can also perform a 360° tipping bucket flip within a three-dimensional space. It realizes the multi-dimensional and multi-directional movement of the ball mill tank, improves the degree of disordered movement of the grinding ball and materials, and grinds the entire material without dead corners in the grinding tank, making the ground materials more even and fine, and can solve the problem of some materials sinking to the bottom and sticking to the tank. .

Applications

QXQM-12 all-round planetary ball mill is widely used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, environmental protection and other departments. It is suitable for electronic ceramics, structural ceramics, magnetic materials, lithium cobalt oxide, manganese acid Lithium, catalyst, phosphor, long afterglow luminescent powder, rare earth polishing powder, electronic glass powder, fuel cell, zinc oxide varistors, piezoelectric ceramics, nanomaterials, wafer ceramic capacitors, MLCC, thermistors (PTC, NTC ), ZnO varistors, dielectric ceramics, alumina ceramics, zirconia ceramics, phosphors, zinc oxide powders, cobalt oxide powders, Ni-Zn ferrites, Mn-Zn ferrites and other products.

Features

The equipment shell has a professional appearance design and industrial shape, and is leanly manufactured, exquisite and precise; the machined parts adopt CNC processing technology, and the transmission gears are made of special materials and precision gears to ensure that the equipment is stable, safe and low-noise when running at high speed; the flipping motor is equipped with a brake lock The stop function can realize turning and stopping at any angle, which is safe and reliable.

TENCAN Powder QXQM-12 Ball millSpecifications

| LIST | VALUE |

|---|---|

| Transmission mode | gear drive |

| Operating Mode | Two or four ball milling tanks work simultaneously |

| Maximum sample loading | Two-thirds of the Volume of the ball mill tank |

| Ball mill tank Volume | 0.05L-25L per can, total Volume 0.2L-100L |

| Feed particle size | Soil material ≤ 10mm, Miscellaneous material ≤ 3mm |

| Minimum discharge particle size | 0.1μm |

| Speed regulation mode | Frequency conversion stepless speed regulation |

| Processing Capacity | 12L |

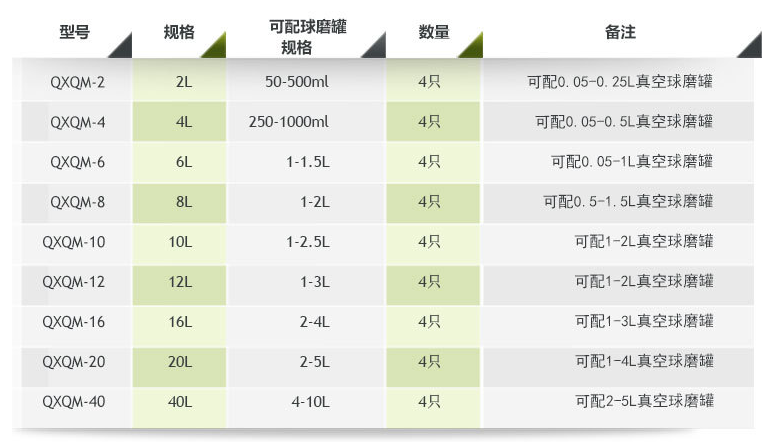

| Can be equipped with ball mill tank specifications | 1~3L |

| station number | 4pcs |

| Can be equipped with ball mill tank specifications | 1~2L |

| Power | 220V-50HZ |

| Inverter Power | 1.5kw |

| Total running time | 1-9999min |

| alternate running time | 1~999min |

| Adjustable Rotation speed - revolution | 35~290rpm |

| Noise level | 60±5dB |

| Motor Power | 1.5kw |

| Speed regulation mode | Frequency conversion speed regulation |

| Device Weight | 420kg |

| Equipment Volume | 1360*850*930mm |

| Adjustable Rotation speed - Rotation | 70~580rpm |

TENCAN Powder QXQM-12 Ball mill Packing list

machine X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

QXQM-12

QXQM-12