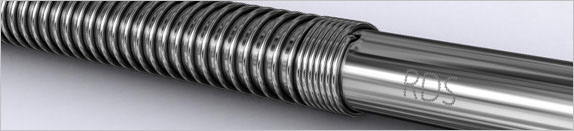

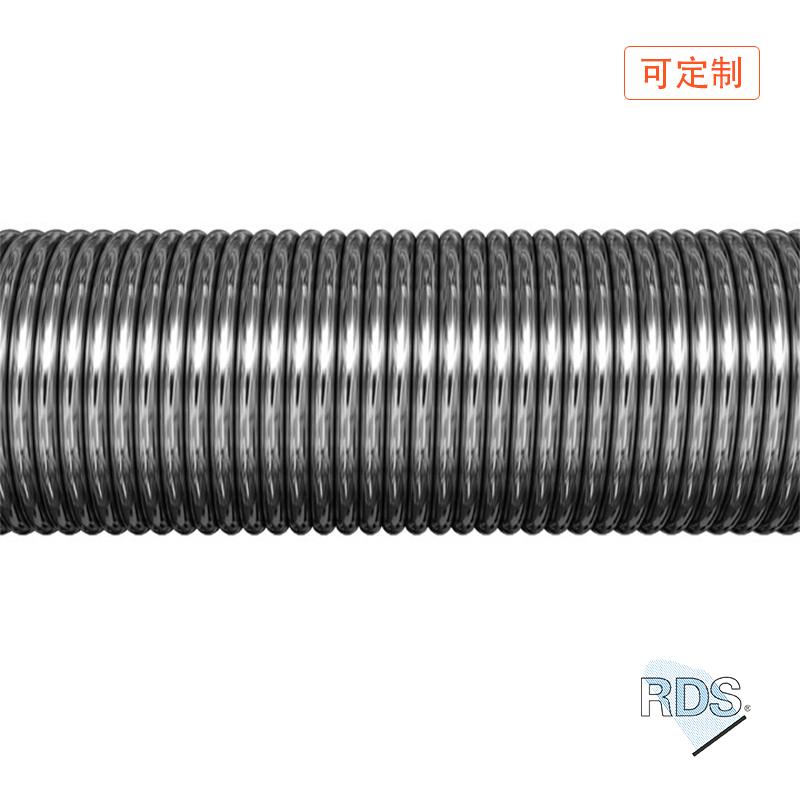

RDS No. 75 Coating Metering rod 190.5μm/100mm wire-wound process, can be customized

RDS No. 75 Coating Metering rod 190.5μm/100mm wire-wound process, especially suitable for printing, tape, film, sticker, Wallpaper, label Spreader for rod film, precise control.

RDS

RDS-

Japan OSP-09 L2000φ 16 custom coating rod 9μm/2m

Login -

Japan OSP-07 L2000φ 16 Coating Metering rod 7μ/2m

Login -

OSP-32 L2000mm φ 16mm Production Coating Metering rod Total length 2m Surface Eletroplating

Login -

OSP 100um φ 10mm L500mm custom production line rod, Total length 50cm

Login -

Japan OSP-100 L2000φ 16 Coating Metering rod groove 100μm/2m

Login

RDS develops and produces wire rods that are widely used in printing and packaging, window films, tapes, release liners, photovoltaic films, wall coverings, specialty paper and other industries. It can be customized according to the different needs of customers.

Common coater Mayer rod configurations

SINGLE MAYER ROD (COMMON)

DOUBLE MAYER RODS

Meyer rod with support rollers

Double-sided configuration

Coating rod type

1. Wire winding rod (commonly used)

The original Mayer-bar was popularized by Charles Meyer in the 20s of the last century and is very popular today. Coating by Mailer is one of the three main coating methods at present. The vast majority of coaters use these wire rods

2. Coated light sticks

RDS coating light bars are commonly used to coat paper, cardboard or plastic film with pre-dosed coatings. The thickness of the coating is determined by the pressure (the rolling action of the applicator) or the tension of the fabric. RDS smooth rods can meet the requirements of any surface treatment, and the RDS coating smooth rod hard chrome plating process can significantly extend the service life of the rods.

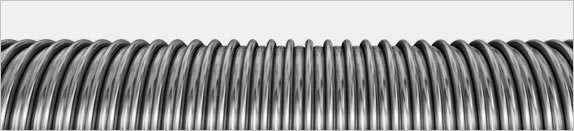

3. Open coating rod

For higher viscosity coatings, open wire rods reduce clogging and eliminate stitches. The grooves created by spaced wrap lines are (see picture) and are shallow and allow heavy paint to flow better. The smaller lines create a small break in the paint flow so that the paint can be soaked more completely. Although open wire rods are not as durable as double spools, they are also less expensive.

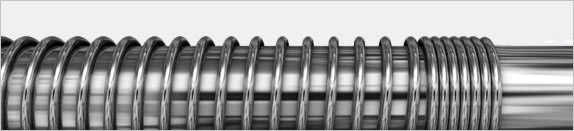

Fourth, double winding coating rod

For higher viscosity coatings, double wire wound rods reduce clogging and eliminate stitches. The grooves created by wrapping smaller lines around a larger tip (see picture) are wide and shallow, allowing heavy paint to flow better. The smaller tip line creates a smaller break in the paint flow so that the paint can be saturated more completely. Although double spooled wire bars are more expensive than open wire bars, they are also more durable.

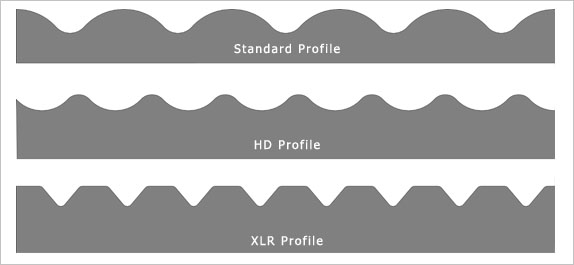

5. Special shape coating rod

The shape of a standard formed wire rod is very similar to that of a wire-wound wire rod, with the same spacing and peak radius. The wide shallow grooves of the HD profile wire rods are suitable for higher viscosity coatings (similar to double wound & open wire rods). The flat peak feature of the XLR profile greatly increases the wear resistance of the wire rod and prolongs the service life of the wire rod.

Application

| The major industries for production rods include the following: | Production rod application industry |

| a) Specialty Papers | Specialty papers |

| i) Fine Printing Paper | Fine printing paper |

| ii) Wall Coverings | Wallpaper? Wall paints, wall coverings? |

| iii)Book Covers | Book covers? Book covers? Cover? |

| iv)Bag Stock | |

| b) Silicone Release Papers | Silicone release sticker |

| c) Adhesive Tape | Adhesive tape, adhesive tape |

| d) Protective Tape & Film – Construction and Automotive | Protective film, protective belt |

| e) Window Film – Tinted and Protective | Glass curtain wall film, heat insulation film, window film, (coloring and protection) |

| f) Photovoltaic Film (Solar Panels) | Photoelectric Thin Film (Solar Panel) |

| g) Pressure Sensitive Films and Foils | Pressure-sensitive tablets |

| h) Graphic Films – Signage and Vehicle Wrap | Car logos, car stickers |

| i) Paperboard Packaging | Cardboard packaging |

| j) Projection Screens | Projection screens, silver screens, display screens |

| k) Direct Thermal Label Stock | Thermal label stickers |

| l) Thermal Transfer Ribbons | Thermal transfer ribbons |

| m) Tickets and Tag Stock | Tickets, labels, cardboard |

| n) Flexible Packaging | Flexible packaging |

RDS RDS 75#/Φ15.9mm-100cm Coating Metering rodSpecifications

| LIST | VALUE |

|---|---|

| WFT | 190.5μm |

| Total length | 1000mm |

| Effective application width | 800mm |

| clamping length at both ends | 100+100mm |

| Main rod diameter | 15.9mm |

| Wire diameter | 0.08mm |

| Surface process | chrome plating |

| Chrome plating thickness | 6.35μm |

| Production process | Wire-wound process |

| material | Stainless steel 303 |

RDS RDS 75#/Φ15.9mm-100cm Coating Metering rod Packing list

Stainless Steel Rod X1 Transparent Encasement Hose X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- RDS Mayer Rods preparatory passivating film

- One article introduces RDS Applicator rod type and FAQ

- The experimental case of OSP Mayer Rods at inks Moulding [with video]

- Laboratory small coater film video demonstration on Aluminum Panel

- Application of laboratory coater on release paper with glue [video demonstration]

- What problems should I pay attention to when buying a wire rod applicator?

- Frequently Asked Questions for Inventory 2022 Lines, Issue 1

- Mayer Rods VS Film Applicators

- Experimental film coating machine case | Scrape coating slurry on release film

- Pull wire test

RDS 75#/Φ15.9mm-100cm

RDS 75#/Φ15.9mm-100cm