RHOPOINT Krebs Stormer Viscometer Krebs Viscometer

RHOPOINT Krebs Stormer Viscometer provides high Precision viscosity measurement using professional features. Based on the ASTM standard Krebs test method, Viscometer uses a rotor at a fixed speed of 200rpm for direct viscosity measurement using three units Krebs units (KU), centipoise (cP) or grams (g)

RHOPOINT

RHOPOINTRhopoint's PAINTLAB + Krebs viscometers offer high-precision viscosity measurement and professional features.

Viscosity measurement of coatings is required at every stage of the manufacturing process to ensure consistent quality standards.

Many parameters affect the rheological behavior of the finished coating, leading to undesirable effects such as sagging, leveling, flammability, and fogging. Therefore, the use of high-quality measuring instruments is required in quality control to prevent these problems during formulation, manufacturing and application.

features

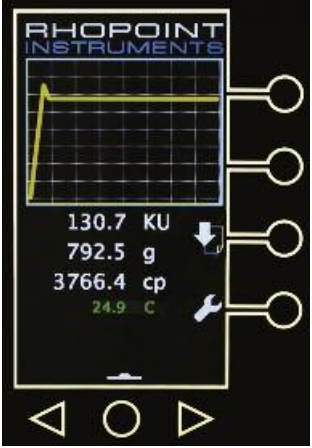

Real-time, high-resolution charts of test samples

The results are displayed on the screen immediately after testing in KU, g, and cP

High-stability motor speed control for accuracy and repeatability of measurements

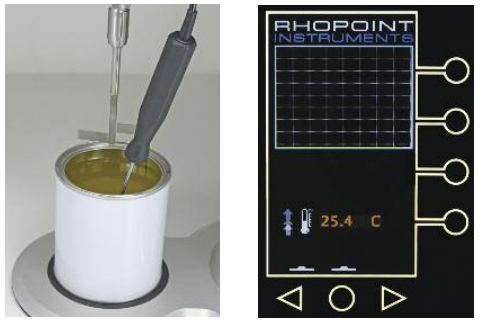

Integrated temperature probe for checking and recording the sample temperature prior to testing

The paddle is automatically lowered to test the height of the selected container

Quick-release magnetic paddle for easy removal and cleaning

Easy-to-clean design - The screen and chassis are easy to clean, even in the harshest environments

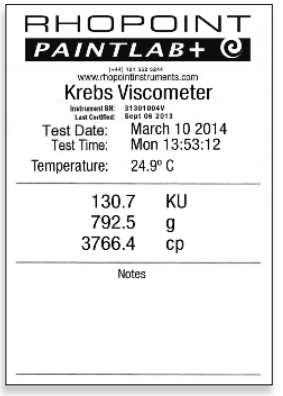

Date/time stamped results are output to the printer

Annual recalibration can be performed by the user

Krebs viscometer features:

Accurate measurements

High-stability motor speed control ensures accuracy and repeatability for every test. Real-time high-resolution graphics allow monitoring of changes during measurements, thus identifying inconsistencies between samples. Immediately after testing in all three units, the measurement results are displayed on the screen.

Professional temperature monitoring

The integrated temperature probe accurately measures and records the sample temperature for each test. Since the viscosity of the sample is affected by the test temperature, accurate monitoring and documentation ensures the reliability of the test results.

Automatic operation

Fully automated operation saves time by accurately lowering the paddles in the plate to the correct height to fit a wide range of standard vessel sizes. Once the test is complete, the paddles are automatically raised to save time during the cleaning process.

The easy-to-use quick-release magnetic paddle rack can be quickly removed for cleaning after use.

Easy-to-clean design

The lab's tough glass makes it easy to remove and remove unintentional splashes and smudges from capacitive sensing buttons and screens. The solvent-resistant anodized aluminum instrument chassis ensures that the instrument is cleaned and restored to its original condition, even in the harshest Operating Environments.

Data transmission

Measurement data including time, date, and test temperature can be printed to a Rhopoint label printer (available as an optional accessory). Printed labels can be attached to each sample for easy identification and documentation of results.

It is also possible to transfer the measurement data directly into Excel using an optional data transfer cable

calibration

Users can remotely perform annual calibration of Krebs viscometers using Rhopoint-certified recalibration kits. Step-by-step instructions and automated validation ensure accurate, traceable results

RHOPOINT Krebs ViscoMeterSpecifications

| LIST | VALUE |

|---|---|

| Display mode | digital display |

| Measurement range | 40~141KU,32~1099g,27~5274cP |

| Rotor specification | Krebs rotor |

| Swirl/spin speed | 200rpm |

| Reproducibility | ±1%F.S |

| Precision | ±1%F.S |

| Container size | 250ml、500ml、0.5pint、1pint |

| Power supply Voltage | 100V/240V |

| Unit display | KU/g/cP |

| Applicable standards | ASTM D562, ASTM D856, ASTM D1131 |

| Environmental temperature | 10~40℃ |

| Dimensions | 460*320*190mm |

| Instrument Weight | 7.25kg |

| Encasement Weight | 10Kg |

| Packaging Dimensions | 680*460*380mm |

| Lifting method | Automatic lift |

RHOPOINT Krebs ViscoMeter Packing list

Viscometer × 1, Krebs rotor, temperature verification probe, traceability calibration certificate, instructional video

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Determination of viscosity of architectural coatings: application of the Stormer Viscometer method

- National Standard for Coating Viscosity Determination [Rotational Viscometer method]

- Which gloss meter can test samples of curved surfaces?

- Why choose Rhopoint IQ instead of a gloss meter?

- Rhopoint Gloss Meter Testing in Special Scenarios FAQ

- what is Viscometer?

- ActiveASTM D562-01-2023

- ActiveASTM D 562-2018

- AbolishGB/T 9269-1988

- ActiveGB/T 9268-2008

- AbolishGB/T 9268-1988

- ActiveGB/T 9269-2009

Krebs

Krebs