US Defelsko PosiTector 6000 FNDS1 Composite Coating Thickness Gauge measurement paints and galvanized layer thickness

The Defelsko PosiTector 6000 FNDS1 Composite Coating Thickness Gauge simultaneously measures the thickness of paints and zinc layers in composite coating systems. The FNDS1 uses the principles of magnetic Induction and eddy Current to simultaneously calculate and display the thickness of individual coatings and zinc layers.

Defelsko

Defelsko-

Defelsko PosiTector 6000 FRS3 Coating Thickness Gauge 90 ° probe

$ 1567.00 -

Germany Nix QNix 4500 + FN1.2 integrated dual-use coating platings Thickness Gauge FeNFe dual-use probe 0-1200μm

$ 950.00 -

Defelsko PosiTest G Coating Thickness Gauge for Eletroplating, thin paint layer, steel phosphating film thickness measurement with certificate

$ 454.00 -

Defelsko FS conventional strip probe 0~1500μm/non-ferrous metal

$ 703.00 -

CHINA CTG-800-3000F Coating Thickness Gauge, Integrated Iron-based Standard Type

$ 209.00

PosiTector 6000 FNDS

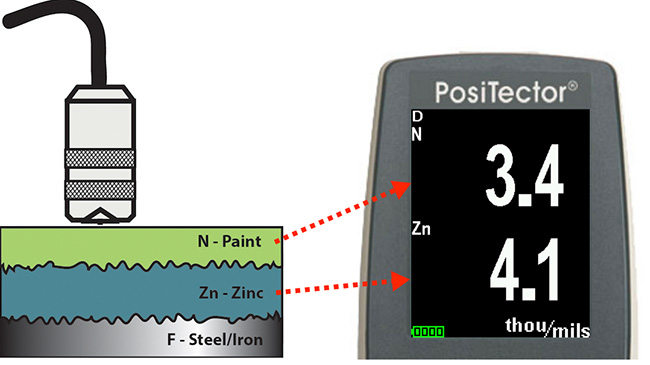

The PosiTector 6000 FNDS probe simultaneously measures the thickness of paint and zinc layers in a composite coating system in a single readout.

Composite coating systems use a combination of two corrosion protection systems – typically painted or powder coated on galvanized steel (thermal, electrical, or zinc-sprayed metal). synthetic corrosion protection due to any individual protection system.

In composite mode, the positector 6000 FNDS uses the principles of magnetic induction (ferrous) and eddy current (non-ferrous) to simultaneously calculate and display individual coating and zinc layer thicknesses. The magnetic induction principle is used to measure the total thickness of the lacquer/zinc layer on a ferrous substrate, while the eddy current Thickness Gauge principle is used to measure the thickness of the paint layer on a non-ferrous zinc layer. The zinc layer thickness is calculated by subtracting the thickness of the paint layer from the total lacquer/zinc layer thickness. The schematic diagram is as follows,

When not available, the gauge is like a traditional ferrous/non-ferrous dual-function gauge (similar to the positector 6000 FNS transducer). It is suitable for measuring non-magnetic properties on steelCoating thicknessThe thickness of the non-conductive coating on a non-ferrous metal substrate.

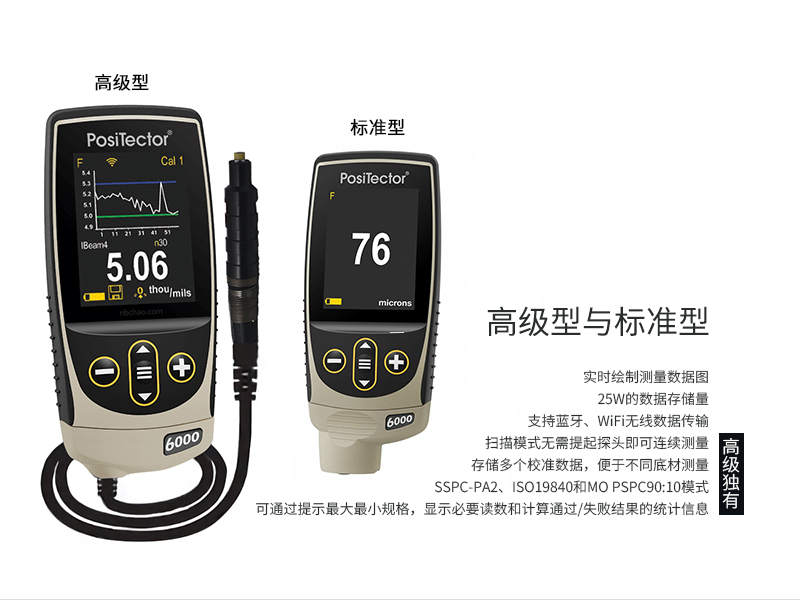

Positicctor Advanced (serial number 730000+) and color LCD are compatible with the Positicctor standard gage. A simple Thickness Gauge update is required.

Recommended reading

★《How do you choose the Defelsko PosiTector 6000 Coating Thickness Gauge?》

★Defelsko PosiTector 6000 Series Coating Thickness Gauge Details (Text Version)

Defelsko PosiTector 6000 FNDS1 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction + eddy Current |

| Measurement range | 0~1500μm |

| margin of error | ±1% |

| Resolution | 0.1μm |

| probe | 6000 FNDS Cabled Probe |

| statistical function | Measurement times, MAX Maximum, MIN Minimum, Average, Standard deviation |

| icon function | without |

| Power Supply | 3 * AAA alkaline battery |

| Standards | ISO 2178/2360/2808、PrEN ISO 19840、ASTM B499/D1186/D1400/D7091/E376/G12、BS3900-C5、SSPC-PA2等 |

| Calibrated Certificate | Yes. |

| Language | Chinese, English |

| Display screen | LCD screen |

| Interface | USB |

| supporting software | Yes. |

| Machine Weight | 140G (without battery) |

| Machine size | 137*61*28mm |

| Data storage | 1000 Measured values |

| Defelsko calibrated standard | STDS1、STDA1 |

| Minimum zinc layer thickness | 0.5 mil (13 um) |

| Coating Accuracy | +(1μm+1%)0~50μm +(2μm+1%)>50μm |

| Zinc layer Accuracy | +(2μm+1%)13~50μm +(4μm+1%)>50μm |

| Probe size | 16mm |

| Probe height | 30mm |

Defelsko PosiTector 6000 FNDS1 Coating Thickness Gauge Packing list

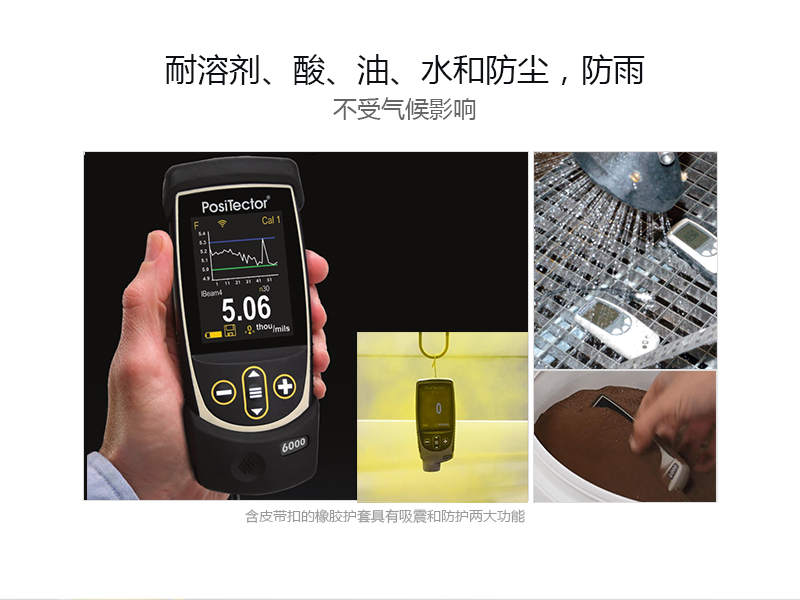

host x1, probe x1, standard test piece (1 set) x1, rubber protective cover with waist clip x1, No. 7 battery x3, certificate x1, manual x1, nylon bag x1, protective film x1, operation manual x1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveGB/T 44757-2024

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveHG/T 5367.1-2018

- ActiveASTM B244-2021

- ActiveISO 2360-2017

- ActiveISO 2178-2016

- ActiveASTM D7091-2022

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ActiveGB/T 1740-2007

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- AbolishJJG 818-1993

- ActiveGB/T 4956-2003

- ISO 2361-1982

PosiTector 6000 FNDS1

PosiTector 6000 FNDS1