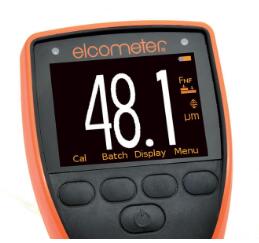

Elcometer 456 eddy current Thickness Gauge A456CNBS+T456CNM3---A

Elcometer 456 eddy current coating Thickness Gauge, model A456CNBS, with T456CNM3---A miniature straight probe, 456CNBS eddy current Thickness Gauge is the Elcometer 456 series basic non-ferrous metal substrate Coating Thickness Gauge, thickness range is 0~500μm, with USB interface.

Elcometer

Elcometer-

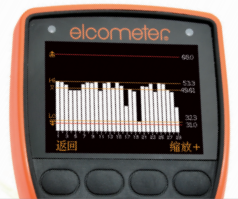

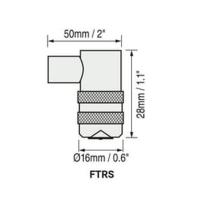

Defelsko FTRS Thickness Gauge Probe

$ 912.00 -

Defelsko PosiTector 200 C3 fiberglass concrete Coating Thickness Gauge

$ 3643.00 -

List Magnetik Pocket TOP-CHECK FE-B Pocket platings Thickness Gauge

$ 1524.00 -

CHINA CTG-800-1500F Paint Thickness Gauge, Integrated Iron-based Standard Type

$ 201.00 -

LANDTEK CM8829S platings Thickness Gauge F magnetic Induction /NF eddy current Ferromagnetic metal substrates Non-ferrous magnetic coatings, platings

$ 392.00

Elcometer 456 Thickness Gauge is divided into 3 types: B (basic type), S (standard type), T (advanced type), from the original Elcometer 456B type to the current 456T type. In addition, it is also divided into integral and split Thickness Gauges.

The split Thickness Gauge provides a variety of probes (probes need to be purchased separately), making measurement more maneuverable.

The British Elcometer 456 A456CNBS split eddy current Thickness Gauge is a basic split eddy current coating Thickness Gauge with a thickness measurement range of 0~30mm.

|  |  |  |

Features

Easy to use

Large buttons are easy to operate even when wearing gloves

Multilingual menu settings

High contrast color LCD with auto-rotation function

High-low limit indicator signs

Factory calibrated and ready to use right out of the box

Readings are accurate

Measurement accuracy ±1~3%

Can be used in accordance with many national and international standards

Thermal stability measurement

Improves resolution readings for thin coatings

Accurate measurement on smooth, rough, thin and curved surfaces

Reliable measurement

High repeatability and reproducibility

2-year console warranty

Full set of traceable inspection certificates provided

Data sets are equipped with date and time stamp functions

solid

Sealed, durable and impact resistant

Dustproof and waterproof, protection level equivalent to IP64

The display is highly resistant to scratches and solvents

Instrument and probe construction are durable

Suitable for use in harsh environments

efficient

Fast reading: 70+/min, using ultrasound/scanning probe: 140+/min

Multiple calibration memory

alphabetic array identifier

User selectable calibration method

Compatible with ElcoMaster® and ElcoMaster® Mobile App

Powerful

Various probes can be used interchangeably

USB interface

Bluetooth® data output to iPhone* or Android⢠device (available in standard and advanced models)

Can be divided into 2,500 groups to store 150,000 data

Capable of measuring coatings up to 31mm thick on metal substrates

Complying with formal quality system certifications such as ISO 9001 requires instruments to properly control, record and calibrate data. Users require that instrument measurement data should be traceable to various national standards. A wide range of nominal and certified diaphragms are available, along with zero plates, to ensure the accuracy of these instruments.

|  |

|

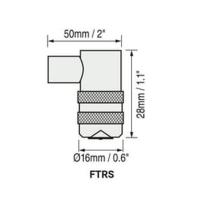

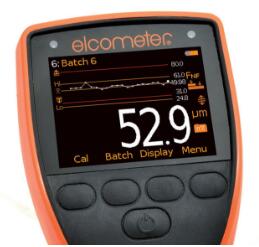

| Large screen display, easy to read, both metric and imperial units | The screen displays up to 8 statistics, and the statistical content is user selectable. | On-screen trend graph shows the last 20 measured values |

|

|  |

| Playback of individual batch readings as numbers or graphs (Advanced) | A variety of probes (need to be purchased separately) are available for a wide range of applications | 2.4" color display allows users to see data more clearly from all angles |

ElcoMaster data management software features

ElcoMaster® helps you review your data and generate professional reports quickly and easily. Built-in wizards guide you every step of the way, from connecting instruments to generating reports.

1. Use the ElcoMaster® software wizard to connect (Bluetooth or USB) to the Elcometer Thickness Gauge to download data quickly and easily.

2. ElcoMaster® can download the measurement results of all inspections from any Elcometer instrument.

3. Data can be stored into a simple file tree by project and detection type . The data is clearly displayed in the table

4. Using ElcoMaster®'s built-in report design, readings can be quickly displayed on images or drawings.

5. Readings from different Elcometer instruments can be printed on the same report - and quickly inserted into standard reports.

6. Suitable for cloud computing.

Elcometer A456CNBS+T456CNM3---A Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Eddy Current |

| margin of error | Depending on the probe |

| Resolution | Depending on the probe selected |

| Minimum measurement surface | Depending on the probe |

| Minimum radius of curvature | Depending on the probe selected |

| probe | Split |

| Calibrated Certificate | Yes. |

| Calibrated mode | Factory calibrated, two point calibrated, zero point calibrated, single point calibrated |

| Unit display | μm/mils |

| statistical function | Number of readings, average value, standard deviation, minimum limit, maximum limit, coefficient of variation |

| Interface | USB |

| Data storage | Last 5 Measured values |

| Power Supply | 2 AA batteries, rechargeable batteries can also be used |

| Standards | AS 2331.1.4, AS 3894.3-B, AS/NZS 1580.108.1, ASTM B 499, ASTM D 7091, ASTM E 376, ASTM G 12,BS 5599,EN 13523-1, IMO MSC.215(82), IMO MSC.244 (83) |

| Display screen | 2.4 " (6 cm) QVGA color TFT display, 320x240 pixels |

| Operating temperature | 80℃ |

| Operating temperature | -10~50℃ |

| Battery life | With 1 reading per second, it can work continuously for up to 24h |

| Protection level | IP64 |

| supporting software | ElcoMaster ® Software |

| Machine Weight | 161G (including battery) |

| Machine size | 141*73*37mm |

Elcometer A456CNBS+T456CNM3---A Coating Thickness Gauge Packing list

Thickness gauge host * 1, thickness gauge probe * 1, calibration shim * 6, zero plate * 1, protective cover * 1, lanyard * 1, factory certificate * 2, operation manual * 1, battery * 2

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ELCOMETER 123 Surface Roughness Tester Operation Method

- Elcometer 456 A456CFNFBI1 Coating Thickness Gauge Beauty Appreciation

- Comparison of two concrete Coating Thickness Gauges

- Eletroplating Nickel Thickness Gauge Selection Case on Steel

- British elcometer Coating Thickness Gauge classification

- What is the accuracy of Elcometer Coating Thickness Gauge?

- One article takes you to know glossiness, reflectance and fog shadow

- Elcometer 506 Adhesion Tester Features

- Elcometer 456 Coating Thickness Gauge

- Elcometer 355 Coating Thickness Gauge Iron and non-iron based probe selection table

- ActiveISO

- ActiveGB/T 44757-2024

- ActiveJB/T 13939-2020

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveGB/T 12967.1-2020

- ActiveHG/T 20720-2020

- ActiveASTM B244-2021

- ActiveISO 2360-2017

- ActiveASTM D7091-2022

- ASTM E376-2019

- AbolishJJG 818-1993

- ActiveHG/T 3885-2006

- ActiveGB/T 6463-2005

- ActiveJB/T 9857-2010

- ActiveGB/T 13452.2-2008

- ActiveGB/T 11374-2012

- ActiveGB/T 4957-2003

A456CNBS+T456CNM3---A

A456CNBS+T456CNM3---A