Muxuan MXY-C2200-20 Laboratory Basket Mill Frequency Conversion Speed Regulation 2200W with 20L Barrel

Electric lift, 4000w power, speed up to 3000rpm, with its own energy-saving inverter, with 20L volume double-layer chill down jacket barrel, made of stainless steel, the separation plate is processed by CNC numerical control of the whole material, and the fineness of grinding can reach 10μm or less.

MuXuan

MuXuan-

MODERNER LSM-2.2B basket sand mill, frequency conversion explosion-proof 20L

Login -

HUXI HMD-400 Multifunctional freezing grinding instrument 15ml stainless steel grinding tank

$ 5613.00 -

MODERNER LSM-370 Basket Sand Mill, Brushless DC 1.25L

Login -

MODERNER SFJ-400 Sanding, Dispersion, Stir Multi-purpose Machine (Variable Frequency Speed Regulation) for Chemical Laboratories

Login -

HUXI HM-MXP Vortex cell crushing instrument 8 * 2ml/600W

$ 269.00

Introduction

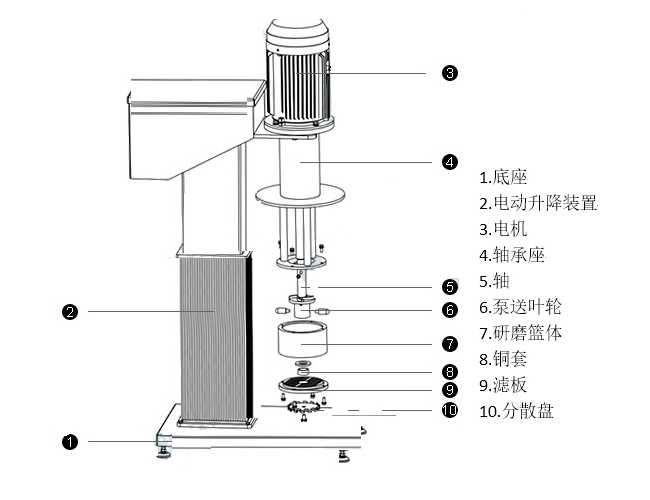

The laboratory electric lifting basket Grinder is an economical wet dispersion grinding equipment developed for scientific research institutions, enterprises and institutions. The equipment can run for a long time, the speed is stable and the noise is low, and the two production processes of dispersing and grinding are completed at the same time, so that the fineness of medium and low viscosity materials can be effectively reduced in a short time.

Application

【Material viscosity】:≤5000 cps(mPas)

[Applicable materials]: Materials that require relatively high fineness, such as interior wall latex paint, industrial paint, wood paint, various color pastes, water-based oil-based inks, pesticide suspensions, etc.

Principle

When the motor of the laboratory electric lifting basket sand mill is running, it drives the lever and the dispersion disc to rotate at high speed, so that negative pressure is generated in the grinding body, so that the material is forcibly sucked into the grinding chamber, and the high-density zirconia beads in the grinding chamber are continuously separated. Collision and friction occur, the particle size of the material becomes smaller and the fineness decreases.

Advantages

High grinding efficiency, good product fineness

The maximum speed of the equipment can reach 3000rpm, driven by the powerful arc impeller kinetic energy, and the zirconia lever makes the grinding medium in the chamber move irregularly, collide and rub against each other at high speed, so that the particle size of the powder becomes smaller rapidly; the grinding fineness Generally, it can reach below 10um, and the liquid-liquid dispersion grinding can reach submicron or even nanometer level. The separation plate is processed by CNC numerical control of the whole material, which has a long service life without clogging and reduces maintenance costs.

Easy to operate and clean

The equipment comes with an efficient energy-saving frequency converter, which can directly control the start-up and speed regulation of the equipment; it is equipped with manual or electric lifting devices, manual lifting is economical and energy-saving, and electric lifting is high-end and labor-saving; it can realize the relative airtightness of the cylinder body and the cover, and the grinding process The medium solvent is less volatilized; the unique design of the grinding chamber, direct solvent circulation cleaning, the whole set of stainless steel design is beautiful and easy to clean; it is very convenient to set the grinding time according to the process and stop regularly.

Small temperature rise, stable product

The batching barrel has a double-layer cooling jacket, and the barrel is mirror-polished, which is beautiful and easy to clean; when the equipment is running, it is cooled by water, which has a good cooling effect, and the conventional temperature rise is less than 10°; the matching material of the same model can be customized There are multiple tubes, which is convenient for color difference and use.

Strong non-standard

The lifting form of the equipment is electric lifting; non-standard explosion-proof type can be customized; material contact parts can be made of SS304 SS316L material; if there are high temperature, high pressure, flammable, explosive, corrosive and other Operating Conditions, it is necessary to provide detailed data and tailor-made custom made.

Equipment selection

| model | power | Basket volume | Standard container |

| MXY-C750 | 0.75Kw | 0.15L | Double layer 1.2L |

| MXY-C1.1 | 1.1Kw | 0.3L | double layer |

| MXY-C1.5 | 1.5Kw | 0.5L | Double layer 10L |

| MXY-C2.2 | 2.2Kw | 1L | Double layer 20L |

| MXY-C4 | 4Kw | 1.5L | Double layer 40L |

| Other parameters | |||

| Speed rpm | 0-3000 | ||

| lifting | electric | ||

| Grinding media | Zirconia | ||

| Grinding media particle size | 1.4-1.6mm | ||

| Lifting stroke | 250mm | ||

| Explosion-proof | no | ||

MuXuan MXY-C2200-20 Lab Basket GrinderSpecifications

| LIST | VALUE |

|---|---|

| Motor power | 2200W |

| Speed regulation range | 0~3000rpm |

| Lifting stroke | 400mm |

| Effective Volume of grinding basket | 1L |

| Barrel Volume | 20L |

| Lifting method | electric |

| grinding medium | zirconia beads |

| Grinding medium particle size | 1.4~1.6mm |

| explosion-proof | No |

MuXuan MXY-C2200-20 Lab Basket Grinder Packing list

host X1, barrel X1, manual X1, certificate of conformity X, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

MXY-C2200-20

MXY-C2200-20