LANDTEK GM-268 Three-angle Glossmeter projection angle 20 °/60 °/85 °

LANDTEK GM-268 three-angle Glossmeter is widely used in floor, plastic, automotive coatings and other gloss measurement. Measurement inspection, GM-268 three-angle Glossmeter has Automatic calibration function and can store 254 readings.

-

Gloss Measurement Instrument JFL-BZ20 (high light smart) JFL 20 degree surface high gloss measurement

$ 395.00 -

KSJ MG6-SM Portable Gloss meter for metal, wide range, self-calibrated with Bluetooth

Login -

PUSHEN WGG-60 Portable Gloss Meter Charging Type 60 °

$ 293.00 -

Surface Glossmeter JFL-B60 (ordinary metal shell) JFL 60 ° Measurement angle

$ 269.00 -

LANDTEK GM-247 20 °/45 °/75 ° Glossiness Meter

$ 615.00

Description

Gloss Meter GM-268 provides 20/60/85 degree measurement, repeatability ± 0.5 GU, range: 0.1-200, widely used for gloss measurement of flooring, plastics, automotive coatings, etc.

Features

* Precise, lightweight shape, easy to carry.

* Automatic calibration, no need for manual adjustment.

* Fully intelligent design, fast measurement.

* Accurate measurement and good repeatability.

* Up to 254 sets of data can be stored.

* Built-in rechargeable lithium-ion battery.

* There is a backlit display, which is convenient for use in low-light environments.

* LANDTEK Gloss Meter GM-268 uses "USB cable output" and "RS-232 cable output" to communicate with a PC.

* Bluetooth Bluetooth data output options available.

Meets standards

LANDTEKGloss meterGM-268 complies with international ASTMD-523, ASTMD1455, ASTM C346, ASTMC584, ASTM D2457, DIN67530, ENISO7668, JISZ8741, MFT30064, TAPPIT480, Gb9754, GB/T13891, GB7706 and GB 8807 standards. The technical parameters are in line with the standard of JJG 696-2002.

Product Applications

LANDTEK GM-268 gloss Tester is widely used in the maintenance of flooring, quality control of surface cleaning, gloss measurement of stones and tiles, inspection of spray paint, quality control of paint, ink and polished metal surfaces, inspection of paint protective layer, wax film, automobile body paint, plastic moldings, detergents, cleaners, masonry industry, and building exterior evaluation.

GM268 gloss meter real picture

Operating instructions

GM268 gloss meter operating manual download address:

![]() LANDTEK GM268 Gloss Meter Operating Instructions .pdf

LANDTEK GM268 Gloss Meter Operating Instructions .pdf

If you want to know more about this model, we recommend that you read it"GM-268 LANDTEK Gloss Meter Unboxing Evaluation"

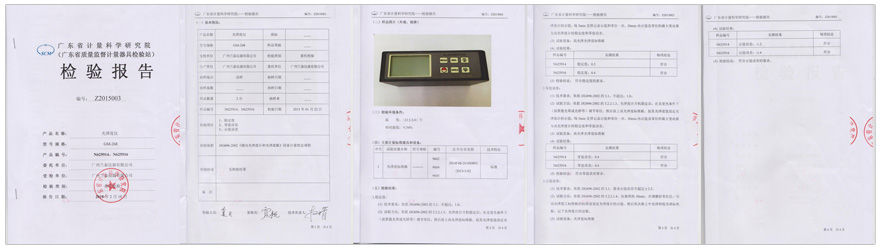

GM268 gloss meter inspection report

Model GM-268, inspected by Guangdong Provincial Institute of Metrology (Guangdong Provincial Quality Supervision and Measuring Instrument Inspection Station); A number of indicators meet the requirements of the standard, have been unanimously recognized by relevant institutions, and are excellent products with excellent technology and reliable quality.

The relevant test indicators and test results are as follows:

Stability: 0.3, 0.4 (meet stability requirements)

Zero error: 0.4, 0.4 (meet the zero error requirement)

Indication error: -1.2, -1.4 (meet the requirements of indication error)

Inspection basis: JJG696-2002 "Mirror Gloss Meter and Gloss Plate" National Metrological Verification Regulations

【Note】The inspection report of GM268 gloss meter comes from the official website of LANDTEK

LANDTEK GlossMeterSpecifications

| LIST | VALUE |

|---|---|

| Measurement angle | 20°/60°/85° |

| Measurement range | 0~200GU |

| Repeatability | ±0.5GU |

| Measuring Area | 7*14mm |

| error of indication | ±1.2GU |

| Graduation | 0.1GU |

| Standards | ASTM D523、ASTM D1455、ASTM C346 、ASTM C584、 ASTM D2457、DIN67530、ENISO7668、JISZ8741、MFT30064、TAPPIT480、 Gb9754、 GB/T13891、GB7706、GB 8807 |

| Interface | USB interface, RS-232, Bluetooth |

| Data storage | 254 groups |

| Operating language | Chinese |

| Dimension | 140*45*75mm |

| Weight | 305G (without battery) |

| Power Supply | Built-in rechargeable ion battery |

| software | Yes. |

| Display | LCD with blue backlight |

| Operating temperature | 0~40℃ |

| Stability | ±0.4GU |

| Relative Humidity | <85%RH |

LANDTEK GlossMeter Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Universal Testing Machine Selection Pit Avoidance Guide: Don't Ignore These Parameters

- Low Temperature Universal Testing Machine Selection: Requirements for equipment performance in low temperature environment

- Universal Testing Machine in high temperature environment: high-temperature chamber matching and accuracy control

- Large Industrial Universal Testing Machine Selection: Range, Stability and Durability Considerations

- Small Laboratory Universal Testing Machine Selection: Cost-effective Model Recommendation

- Temperature, Humidity and other environmental factors affect the long-term stability of Universal Testing Machine

- How tensile testing devices perform field validation of load sensors (using standard weights)

- Solution of extensometer calibrating and signal drift

- Common Fault Phenomena and Diagnostic Steps of UTM Load Sensor

- Universal Testing Machine Daily Maintenance Checklist (weekly, monthly, annual)

- ActiveGB/T 13217.2-2024

- ActiveISO

- ActiveGB/T 42789-2023

- ActiveGB/T 13448-2019

- ActiveGB/T 7707-2008

- ActiveGB/T 21867.3-2008

LANDTEK

LANDTEK