Defelsko PosiTector 200 D3 Non-metallic Substrate Coating Thickness Gauge Premium Edition

Measurement principle Ultrasonic, Measurement range 50~7600μm, error range +/- 3%, application of thick and soft coatings such as polyurea, asphalt neoprene, very thick polymer, Interface Bluetooth 4.0, PosiTector APP, ALE API, Data storage 250000 Measured values

-

Leeb242 (N1) Coating Thickness Gauge can print measurement data

Login -

Leeb221 Coating Thickness Gauge to detect the thickness of non-conductive coated Films on non-metallic substrates

Login -

Defelsko FKS thick coating probe, thickness 0~13mm

$ 912.00 -

DUBAN DB20-CM212S Statistical Coating Thickness Gauge split probe 0~1250µm

$ 580.00 -

Defelsko PosiTector 6000 FRS3 Coating Thickness Gauge 90 ° probe

$ 1567.00

PosiTector® 200

Coating Thickness Gauge for non-metallic substrates

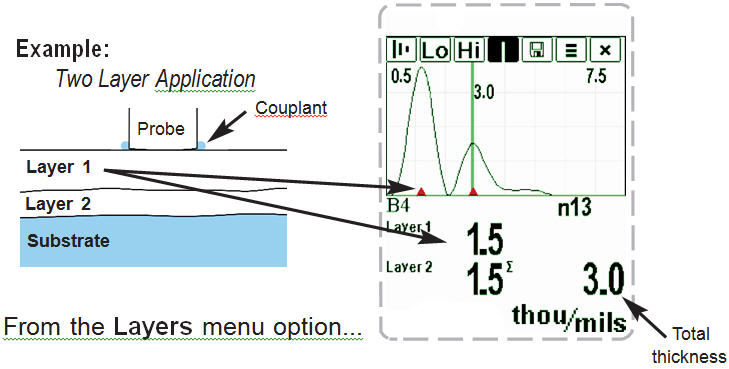

Proven technology: Uses proven ultrasound technology to non-destructively measure a wide range of applications. Measure the coating thickness of wood, concrete, plastic, etc. The advanced model can measure up to 3 layers of graphics.

Convenient measurement: Most applications do not require calibration adjustments

Good protection: solvents, acids, oils, water and dust - weatherproof

High Compatibility: PosiTector Interchangeable Platforms - Connect any PosiTector probe to a single meter body

Links work: USB, WiFi, and Bluetooth connectivity for PosiSoft PC, Mac, and Smartphone software

With Calibration Certificate: Calibration Certificate shows traceability to NIST or PTB (long form)

Standards: Complies with ASTM D6132 and ISO 2808

Product Features

Simple

Prepare for measurement - most applications do not require calibration adjustments

Enhanced one-handed menu navigation

Flashing display - ideal for use in noisy environments

The RESET function enables an immediate factory reset

durable

Solvents, acids, oils, water and dust - weatherproof

Shock-absorbing protective rubber holster with belt clip

Two-year warranty on the meter body and probe

accurate

Calibration certificate showing traceability to NIST or PTB (long form)

Responsive sensors provide fast, accurate readings

Proven non-destructive ultrasound technology in accordance with ASTM D6132 and ISO 2808

versatility

High-contrast backlit display for bright or dark environments

Mils/Microns switchable

Selectable display language

Flip the display for a front-facing view

Use alkaline batteries or rechargeable batteries (built-in charger)

powerful

The statistical mode continuously displays/updates the mean, standard deviation, min/max thickness and readings while measuring

Sealed USB port for quick and simple connection to PC and continuous power. USB cable included

Software updates over the network ensure that your gage is new

Screen Capture - Record and save images to a USB flash drive for recording and viewing

Software solutions for viewing, analyzing, and reporting data

Each stored measurement is marked with a date and time

Model selection

|

|

|

| 200 B3 | 200 C3 | 200 D3 |

| apply | apply | apply |

| Polymer coatings such as wood, plastic, etc | concrete, fiberglass and other coatings | Thick and soft coatings such as polyurea, bituminous neoprene, very thick polymers |

| Measuring range* | Measuring range* | Measuring range* |

| 13~1000μm | 50~3800μm | 50~7600μm |

| accuracy | accuracy | accuracy |

| ± (2 μm + 3% of reading) | ± (2 μm + 3% of reading) | ± (20 μm + 3% of reading) |

| Minimum single layer thickness** | Minimum single layer thickness** | Minimum single layer thickness** |

| 13μm | 50μm | 500μm |

| Certified thickness standards | Certified thickness standards | Certified thickness standards |

| STDA3 | STDP6 | STDP1 |

*Scope restrictions apply only to polymer-based coatings. D-probe polyurea ranges from 50 to 5000 μm (2 to 200 mils).

**Only for multi-tier applications. Depends on the material to be tested.

Version selection

| features | Standard Edition | Premium |

| Measure the total thickness of the coating system | ✔ | ✔ |

| Measure up to 3 layers separately in a multi-coat system | ✔ | |

| Graphical analysis | ✔ | |

| Statistical mode | ✔ | ✔ |

| Storage capacity | 250 | 100000 (1000 sets) |

| On-screen batch annotations - Add annotations, change batch names, and more using the built-in QWERTY keyboard | ✔ | |

| Multiple stored calibration adjustments for measuring a wide range of substrate conditions | ✔ | |

| Data transmission | ||

| Sealed USB port for quick and simple connection to PC and continuous power.USB cable included. | ✔ | ✔ |

| Bluetooth 4.0, PosiTector APP, portable printer (optional), BLE API interface for third-party software integration | ✔ | |

Defelsko PosiTector 200 D3 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | ultrasound |

| Measurement range | 50~7600μm |

| margin of error | ±3% |

| application | Thick, soft coatings such as polyurea, asphalt, neoprene, very thick polymers |

| Calibrated Certificate | Traceable to NIST or PTB (long form) |

| statistical function | Multi-layer coating system for measurement of up to 3 layers |

| Unit display | μm/mils |

| statistical function | MAX Maximum, MIN Minimum, Average, Standard deviation |

| icon function | Yes. |

| Interface | COR4.0,Positector APP,ALE API |

| Data storage | 250000 Measured values, 1000 groups |

| Power Supply | Alkaline or rechargeable batteries |

| Standards | ASTM D6132、ISO 2808 |

| Language | 16 languages including Chinese and English are available |

| Print function | Bluetooth printer (to be purchased separately) |

| supporting software | PosiSoft PC、PosiTector App |

| Machine Weight | 140G (without battery) |

| Machine size | 135*61*28mm |

Defelsko PosiTector 200 D3 Coating Thickness Gauge Packing list

host x1, probe x1, standard foil x1, coupling agent x1, rubber protective cover with waist clip x1, No. 7 battery x3, nylon portable soft bag x1, English manual x1, certificate x1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle and method of ultrasonic testing (UT) coating thickness

- Types and Usage Methods of Coupling Agent for Thickness Gauges

- ActiveASTM -2022

- ReplacedNF EN ISO 2808-2007

- Active 901-2021

- Active 10254-2022

- AbolishGB 15442.1-1995

- ActiveGB/T 37361-2019

- ActiveGB 28375-2012

- ActiveGB 12441-2018

- ActiveGB 14907-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveGB/T 14907-2018

- AbolishGB 14907-2002

- ActiveGB 28374-2012

- ActiveGB/T 4893.5-2013

- ActiveASTM D 6132-2020

- ZB 51004-1985

- AbolishGB/T 12441-1998

- AbolishGB/T 14907-1994

- ActiveGB/T 17459-1998

Defelsko

Defelsko PosiTector 200 D3

PosiTector 200 D3

PosiTector 200 D1

PosiTector 200 D1