YIHENG SX2 - 2.5-10 TP experimental muffle furnace volume 2L maximum temperature 1000 ℃

YIHENG SX2 - 2.5-10 TP experimental muffle furnace adopts good wirecoil for heater heating element, microcomputer PID precise temperature control, SX2 - 2.5-10 TP experimental muffle furnace liner is made of stainless steel, the design temperature is 1000 ℃, the tank volume is 2L.

-

YIHENG SX2-10-12NP muffle furnace (programmable Box-Type Resistance Furnace) 1200 ℃ design temperature

$ 1679.00 -

HUITAI 16-10TP intelligent muffle furnace volume 80L ceramic fiber furnace

Login -

JINGQI SX2-8-10TP integrated ceramic fiber muffle furnace

$ 1625.00 -

BOZHEN BZ-4-10 integrated Box-Type Resistance Furnace high aluminum liner box heater 1000 ℃/7L

$ 403.00 -

BENTING CSX2-8-10 experimental Box-Type Resistance Furnace 1000 ℃/16L

Login

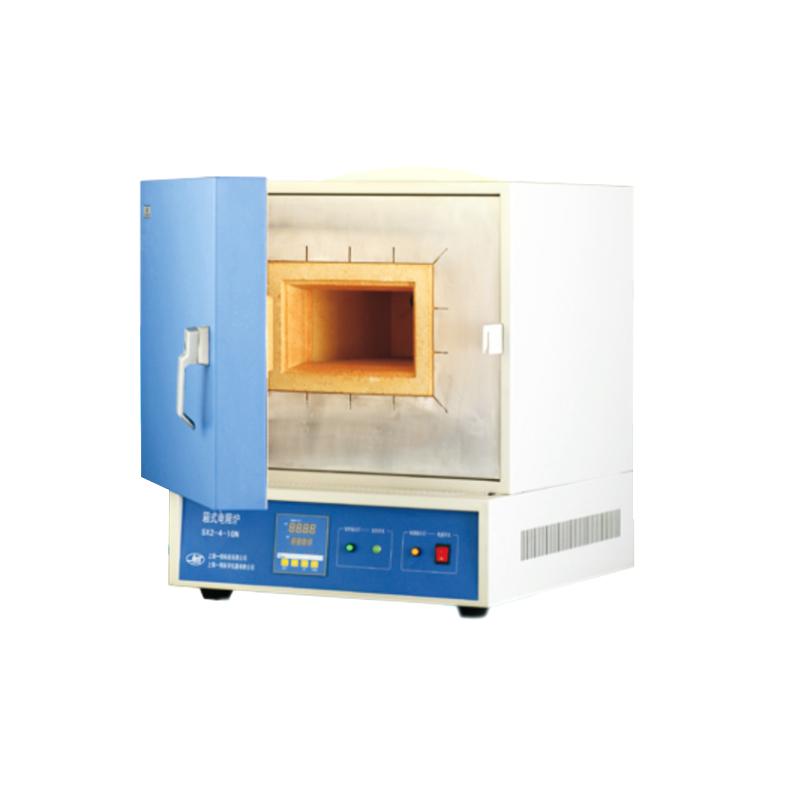

SX2-2.5-10TP Muffle Furnace Overview

Yiheng SX2-2.5-10TP muffle furnace is a programmable box-type Resistance Furnace with a design temperature of up to 1000°C and a volume of 2L.The furnace chamber of SX2-2.5-10TP muffle furnace is ceramic fiber, the heating element is good electric furnace wire, and it is controlled by microcomputer PID.

Features

1. SX2-2.5-10TP muffle furnaceIt is a multi-stage programmable controller, 30 programs, each section can be set to rise or stay, and provides the function of programmatic temperature, time and heating power cycle to achieve automatic control and operation.

2. The inner tank and box panel in the furnace are made of stainless steel, which has the advantages of corrosion resistance, not easy to rust, and high temperature unchanged.

3. SX2-2.5-10TP muffle furnaceThe unique design of the furnace door makes the door opening safe and simple to operate, and also ensures that the high-temperature hot gas in the furnace will not leak.

4. The door is well sealed, so that the heat loss is very small, and at the same time it increases the uniformity of the temperature in the furnace.

How safe is it?

1. SX2-2.5-10TP muffle furnaceWhen the operator opens the furnace door, the safety switch of the furnace door automatically disconnects the heating power supply to ensure safe operation.

2. The muffle furnace is providedA variety of security protection measures, such as:Overcurrent, overVoltage, overheating, etc., to ensure the safety of Resistance Furnace use.

3. Ceramic fiberboard can be used as thermal insulation material, which has good thermal insulation effect and low surface temperature of enclosure.

Product Applications

SX2-2.5-10TP muffle furnace is suitable for industrial and mining enterprises, scientific research institutions, chemicals, metal processing industry, ceramic industry and other industries.

Actual picture of the product

YiHeng Box-Type Resistance Furnace (programmable)Specifications

| LIST | VALUE |

|---|---|

| maximum temperature | 1000℃ |

| Heating Elements | wirecoil for heater |

| Furnace Volume | 2L |

| Heating power | 2.5KW |

| Furnace size | 120*200*80mm |

| Power supply Voltage | 220V 50Hz |

| Dimension | 400*580*610mm |

YiHeng Box-Type Resistance Furnace (programmable) Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Universal Testing Machine Selection Pit Avoidance Guide: Don't Ignore These Parameters

- Low Temperature Universal Testing Machine Selection: Requirements for equipment performance in low temperature environment

- Universal Testing Machine in high temperature environment: high-temperature chamber matching and accuracy control

- Large Industrial Universal Testing Machine Selection: Range, Stability and Durability Considerations

- Small Laboratory Universal Testing Machine Selection: Cost-effective Model Recommendation

- Temperature, Humidity and other environmental factors affect the long-term stability of Universal Testing Machine

- How tensile testing devices perform field validation of load sensors (using standard weights)

- Solution of extensometer calibrating and signal drift

- Common Fault Phenomena and Diagnostic Steps of UTM Load Sensor

- Universal Testing Machine Daily Maintenance Checklist (weekly, monthly, annual)

YiHeng

YiHeng