Defelsko STDA1 calibrated coating metal plate PosiTector6000

Defelsko STDA1 calibrated coating metal plate is coated with epoxy Resin on aluminum, suitable for PosiTector6000 N/NS/NRS/FN/FNS/FNRS/FNDS probe calibrated, the thickness of STDA1 coated metal plate is 0μm, 75μm, 250μm, 1500μm.

Defelsko

Defelsko-

Defelsko PosiTector 6000 NAS3 Coating Thickness Gauge Aluminum oxide film

$ 1818.00 -

Defelsko NAS split thin coating probe

$ 1049.00 -

QNix4200/5 magnetic Induction Coating Thickness Gauge 0-5000um

$ 1142.00 -

Defelsko PosiTector 6000 FNS1 coated platings Thickness Gauge that automatically converts in magnetic and nonmagnetic environments

$ 1444.00 -

German EPK MiniTest 600 B-N eddy current platings Thickness Gauge, thickness: 0~2000μm

$ 1011.00

Introduction

STDA calibrated coated sheet metal is a non-magnetic aluminum coated with an epoxy-based resin coating.

Certified sheet metal is an excellent choice for verifying the accuracy and operation of coating Thickness Gauges, and is an important part of meeting ISO and internal quality control requirements.

Many organizations require that the accuracy of the gauge be verified at the test site every time the coating Thickness Gauge is put into use, and frequently during use. DeFelsko-certified coating thickness standards with measurements traceable to national metrology institutes are ideal for this purpose.

Features

Used to verify the accuracy and operation of any Type 1 (mechanical) and Type 2 (electronic) magnetic, eddy current or ultrasonic coating Thickness Gauge

Suitable for calibration labs, on-site or factory floors.

Standards with steel or aluminum substrates consist of 4 plates mounted in a protective adhesive.

The polystyrene thickness standard is supplied by a sturdy acrylic storage box in 4 blocks.

Serialized separately to trace back to NIST or PTB - calibration certificate included.

Both metric and imperial units are certified and marked.

The zero plate can be used for certified coated metal sheets and certified polystyrene blocks.

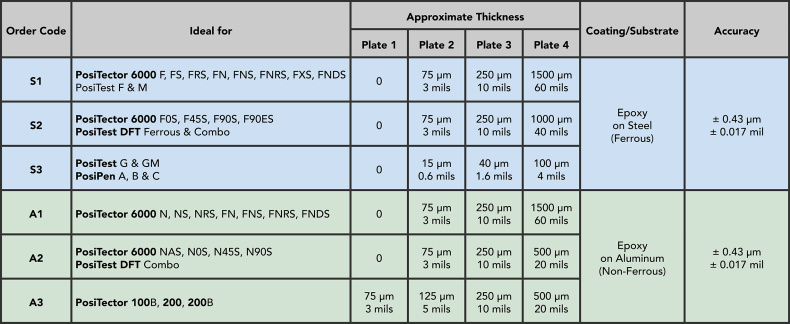

Calibrate the coated sheet metal series model chart

Defelsko STDA1 Calibrated coating metal sheetSpecifications

| LIST | VALUE |

|---|---|

| compatible model | PosiTector6000 N,NS,NRS,FN,FNS,FNRS,FNDS |

| Thickness - Block 1 | 0 |

| Thickness - Block 2 | 75μm(3mils) |

| Thickness - Block 3 | 250μm(10mils) |

| Thickness - Block 4 | 1500μm(60mils) |

| margin of error | ±0.43μm;±0.017mils |

| Coatings/Substrates | (Nonmagnetic) Resin on Aluminium |

Defelsko STDA1 Calibrated coating metal sheet Packing list

Sheet Metal X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- New: Defelsko PosiTest CH cross-cut adhesion Tester

- Application scheme of coating thickness test on wood board [with test video]

- Curved plastic coating thickness test application scheme [with test video]

- PosiTector200C ultrasonic coating Thickness Gauge on concrete coating thickness measurement application

- Defelsko PosiTector 200 Ultrasonic coating Thickness Gauge Chinese version Instructions for use [2023 new version]

- Appearance evolution of Defelsko coating Thickness Gauge to see the progress of industrial testing instruments

- Defelsko PosiTector 6000 coating Thickness Gauge Chinese version Instructions for use [2023 new version]

- Calibration Terms - Coating Thickness Gages

- Application of Defelsko PosiTest OTL furnace temperature Recorder in curing index testing

- Measure gloss with a PosiTector GLS gloss meter

STDA1

STDA1