German EPK MiniTest 735 F1.5 statistical coating Thickness Gauge, thickness measurement 0~1500μm

Split, external F1.5 probe, thickness measurement range is 0~1500μm, error range +/- 0.75%, with Bluetooth interface, support for a variety of Calibration methods, supporting software, can transmit data wirelessly.

ElektroPhysik

ElektroPhysik-

Germany Nix QNix 4500 + FN1.2 integrated dual-use coating platings Thickness Gauge FeNFe dual-use probe 0-1200μm

$ 950.00 -

Defelsko PRB200D Ultrasonic Thickness Gauge Probe PosiTector200D

$ 3157.00 -

Qnix Fe3mm magnetic thickness probe 3000μm

$ 926.00 -

Defelsko F45S split 45 ° micro probe

$ 1049.00 -

LINSHANG LS237 Film Thickness Gauge (for automobile paint thickness detection)

$ 176.00

Introduction

The German EPK MiniTest 735 statistical coating Thickness Gauge combines accuracy and flexibility. Equipped with a Bluetooth interface to wirelessly transfer data to a computer, tablet or smartphone. MiniTest 735 statistical coating Thickness Gauge uses an external probe, which has the advantages of high accuracy and easy measurement, and can be used to measure hard-to-reach places.

Applications

â Non-magnetic coatings such as paint, varnish, enamel, chrome and zinc plating

â Steel substrate or insulating coating such as paint, anodized film or ceramics, etc.

â Non-ferrous metal substrate copper, aluminum, die-cast zinc, copper, etc.

Features

â Can transmit data to computer, tablet or mobile phone client through Bluetooth interface

â Large capacity memory for up to 100,000 readings

â Simple, menu-based operation in up to 20 languages

â Improving accuracy with various calibration modes

â Perfect compensation after temperature changes covers the entire measurement range

â Excellent accuracy and repeatability rely on SIDSP technology

â Limit value monitoring, user-adjustable compensation and correction values ââfor rough base materials

â Continuous measurement mode

â Free software update downloads for main unit and probe via Internet.

plan

Optional probe for MiniTest 735 coating Thickness Gauge

ElektroPhysik MiniTest 735 F1.5 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction |

| Measurement range | 0~1500μm |

| margin of error | ±0.75% |

| Minimum measurement surface | 5mm |

| probe | Line probe |

| Calibrated Certificate | Manufacturer Certificate |

| Calibrated mode | Factory calibrated, zero calibrated, 2 point calibrated, 3 point calibrated, rough Calibration method "rough" |

| Unit display | μm/mm/cm/mils/inch/thou |

| statistical function | Number of readings, MIN Minimum, MAX Maximum, mean, standard deviation, coefficient of variation, single-valued statistics, chunk statistics (conforming to specifications/free configuration) |

| Interface | USB、Bluetooth |

| Data storage | 100000 Measured values |

| Power | 2 AA (AA) batteries; optional rechargeable nickel-metal hydride battery, AA/HR6 type. Battery or rechargeable battery settings are optional to match Rated Voltage. |

| Standards | DIN EN ISO 1461、DIN EN ISO 2064、DIN EN ISO 2178、DIN EN ISO 2360 |

| Language | 20 languages |

| Display screen | LCD |

| Operating temperature | -10~60℃ |

| Battery life | 2 AA (AA) batteries; optional rechargeable nickel-metal hydride battery, AA/HR6 type. Battery or rechargeable battery settings are optional to match Rated Voltage. |

| supporting software | Yes. |

| Machine Weight | 210g |

| Machine size | 157*75.5*49mm |

| Storage temperature | -20~70℃ |

| Calibrate to international standards and norms | ISO international standards organization, SSPC American protective coatings association, "Swedish" Sweden, "Australian" Australia |

| limit monitoring | Output visual and auditory signals |

| Measurement speed | 70 readings per minute in single-value mode; 20 readings per second in continuous mode |

| continuous mode | For quickly identifying thickness changes |

| Standards | DIN EN ISO 2808、DIN EN ISO 3882、ISO 19840、ASTM B 244、ASTM B 499、ASTM D 7091、ASTM E 376、AS 3894.3、SS 184160、SSPC-PA 2 |

ElektroPhysik MiniTest 735 F1.5 Coating Thickness Gauge Packing list

Host × 1, calibrated foil and reference board, operating instructions CD, soft bag and shoulder strap, AA battery × 2, manufacturer's certificate, MSoft7 basic version data transfer software.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Introduction of nondestructive thickness testing principle and instrument

- Correct use of Film Thickness Gauge

- What coating thickness instrument is used to measure thickness on rough surfaces?

- What is the significance of coating Thickness Gauge calibration? How to calibrate? When to calibrate?

- Small coating thickness test which coating Thickness Gauge measurement is more accurate?

- Why you need a calibrated coating Thickness Gauge before testing

- Measuring methods of coating Thickness Gauge

- Choice of Coatings

- Principle and Application Analysis of Coating Thickness Gauge

- Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveGB/T 42541-2023

- ActiveGB/T 7991.5-2014

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveISO 2178-2016

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- AbolishASTM G12-07-2013

- ActiveJB/T 7663.2-2007

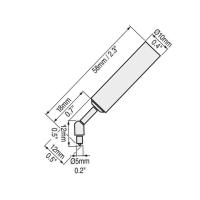

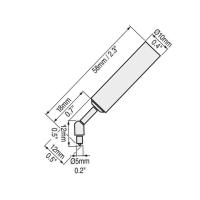

MiniTest 735 F1.5

MiniTest 735 F1.5