MODERNER NGG dry heat test pot, wood-based panel heat resistance test

Dedicated to wood-based panel dry heat resistance performance test, in line with GB standard design, NGG dry heat resistance test pot is suitable for 230mm long specimens.

Moderner

Moderner-

XINGHUO ZTT-930 Protrusion road sign Anti-Impact performance Tester

$ 569.00 -

CHINA NBC-YX-6050 Manual 2D Imager 600 × 500mm

$ 7160.00 -

YUZHOU YM-1 Metallographic sample pre-mill, wet grinding water supply system, throwing plate diameter 230mm

$ 337.00 -

YINUO YN-CP01 Sheet Former, diameter 200 drying non-drying optional

$ 12322.00 -

CHINA NBC-YX-5040 Manual 2D Imager 500 × 400mm

$ 6688.00

use

Uses of dry heat resistance test pot:

The dry heat resistance test pot is mainly used for the dry heat resistance test of wood-based panels and decorative wood-based panels to determine the resistance of the surface decoration layer to hot objects. Applicable to: GB/T15102, GB/T17657, GB/T18102 standards.

Application of dry heat resistance test cup:

This test cup is manufactured according to the technical requirements in the national standard GB4893.385. Used for the determination of the paint film on the surface of furniture, and also for the determination of the dry heat resistance of polyester polyurethane wood lacquer and UV-cured wood lacquer.

Measurement steps

Determination steps of dry heat resistance test pot:

1. Put the test piece (size of test piece: length: 230mm±5mm; width: 230±5mm) in an environment with a temperature of (23±2)°C and a Relative Humidity of (50±5)% for 7 days.

2. Check the bottom of the test pot, there must be no surface damage and adhesions.

3. Put enough glycerin tristearate into the cylindrical container, the liquid surface is 15mm from the top, put the container on the heating source, and raise the temperature to about 180°C. Insert a thermometer into the container, and the mercury bulb bottom of the thermometer is about 6mm from the bottom of the container. Raise the temperature of the oil to 185°C under constant stirring, then move the container to the heat insulation plate, and keep stirring to lower the temperature to (180±1)°C.

4. Immediately place the container on the surface of the test piece and leave it for 20 minutes without stirring. The container was removed and the test piece was allowed to cool for 45 minutes.

5. The light is projected onto the test piece from various incident angles, and the surface of the test piece is observed with the naked eye for any changes such as bubbling, cracking, discoloration or obvious light fading.

Determination steps of dry heat resistance test cup

1. Check the bottom of the copper test cup, and there must be no surface damage and adhesion.

2. Inject 100±1g of mineral oil.

3. Put the copper test cup on the electric furnace and heat until the oil temperature exceeds the specified temperature by 10°C (safety must be ensured during the heating process), place the test cup on the diaphragm heating pad with crucible tongs, let the oil temperature drop slightly, and constantly stir the minerals oil so that the oil temperature is evenly distributed.

4. When the oil temperature in the copper test cup reaches the specified temperature, move the test cup to the test area and let it stand for 15 minutes.

5. When the specified time is reached, take the test cup away, lightly test the test area with filter paper, and mark the test temperature. Let stand for 16-24h.

6. Lightly test the test area with filter paper, and inspect as required.

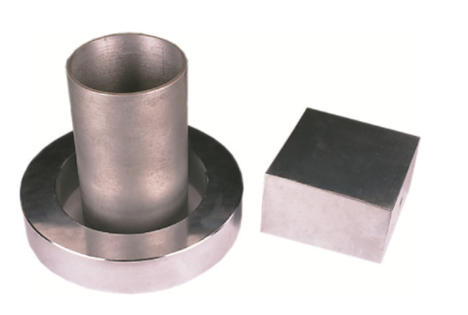

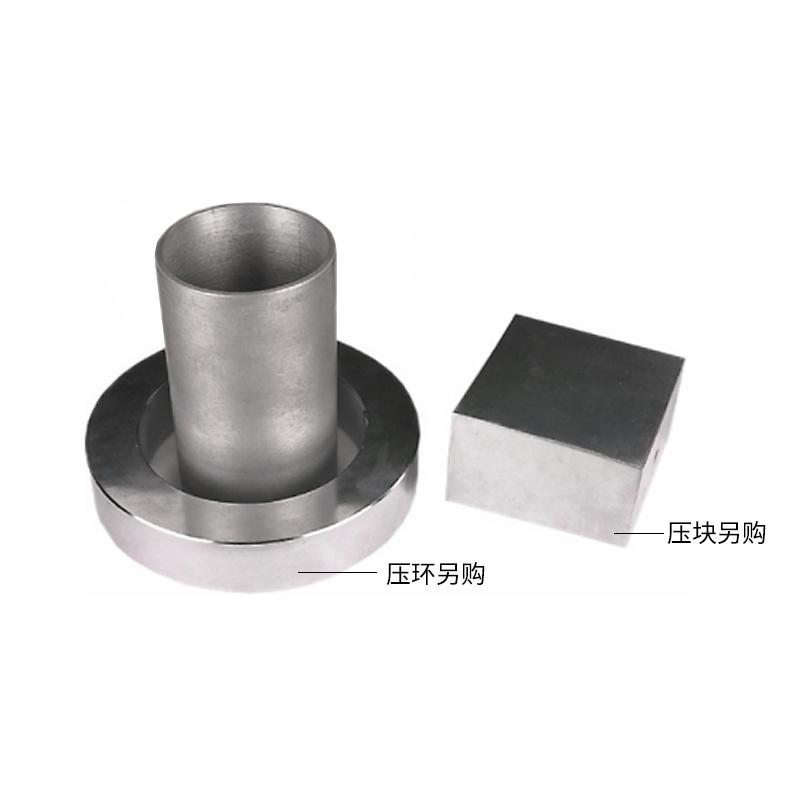

Moderner NGG Resistance to dry heat test potSpecifications

| LIST | VALUE |

|---|---|

| Outer diameter of dry hot pan | F87 ± 1mm |

| Dry heat resistant pan high | 150±5 mm |

| Dry and hot pan with thick bottom | 2.5±0.5mm |

| Outer diameter of pressure ring | F180 ± 1mm |

| Inner diameter of pressure ring | F. 120 ± 1 mm |

| Ring Weight | About 4Kg |

| Briquetting overall dimension | 100mm × 100mm × 64 mm (L × W × H) |

| briquetting Weight | About 5Kg |

Moderner NGG Resistance to dry heat test pot Packing list

Dry heat pan X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

NGG

NGG