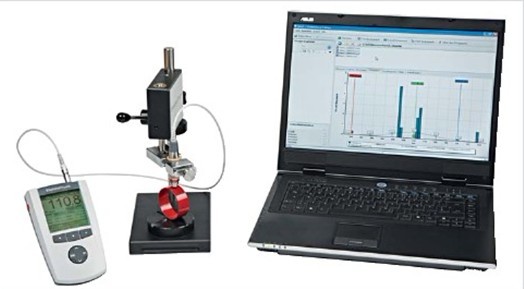

EPK MiniTest 7400 Coating Thickness Gauge

With its innovative user interface concept combined with convenient data management, the new MiniTest7400 Coating Thickness Gauge is the ideal solution for today's measurement systems.

ElektroPhysik

ElektroPhysik-

PUSHEN PIG Multipurpose Dry-Film Detector

$ 640.00 -

Germany Nix QNix 4500 + FN5 integrated dual-use coating platings Thickness Gauge FeNFe dual-use probe 0-5000μm

$ 1428.00 -

German EPK MiniTest 735 N0.7 eddy Current Thickness Gauge, Thickness 0~700μm

Login -

Germany EPK MikroTest S20 McCourt enamel layer Thickness Gauge, thickness measurement: 7.5~ 20mm

$ 2879.00 -

DONGRU DR380 portable Film Thickness Gauge magnetic and eddy current Thickness Gauge

$ 419.00

Thanks to the innovative user interface concept and convenient data management, the new MiniTest7400 is the perfect solution for today's measuring systems.

Advantages of the new concept

Intuitive menu controls and contextual online help are easy to use. The large backlit keys make it comfortable to operate even when wearing gloves. The large backlit graphic display provides excellent viewing and is very convenient to use even at night or in conditions of very low visibility.

Configuration management helps the MiniTest 7400 simplify calibration and parameter setting, requiring no specialized skills and completing difficult measurement tasks in the shortest possible time. Professional data management, like a PC, provides quick folder creation and easy batch group setup. In addition to the numerical display of readings, the hierarchy of statistical values and readings includes trend graphs and histograms, process capability indices "Cp" and "Cpk", and group statistics. Erroneous readings can be removed from the batch group to prevent incorrect statistical values.

The large data storage is necessary for data management, storing up to 250,000 readings in batches of up to 500. To meet the requirements of high-precision measurements, the 7400 probe can be calibrated to 5 points (including zero). The preset calibration methods comply with industry guidelines and measurement standards of ISO 19840, SSPC, "Sweden", "Australia". In addition, the special calibration method for extension is also suitable for the measurement of rough surfaces.

In order to facilitate the creation and evaluation of sets of measured values and the output of various data formats, the computer software package "MSoft 7 Professional" is included as standard. The software outputs data such as text, Excel® analysis sheets, or PDF documents, and allows notes and annotation entries. Features Pictures of the measured samples can be added to the data report.

Equipped with numerous interfaces, the MiniTest 7400 can be connected to a wide range of external devices. An infrared interface (IrDA®1.0) is available as standard. A multi-purpose junction box can be used as a USB interface to connect various devices such as borrowed power supplies, headphones, foot switches or alarms. For a single device connection, RS 232 and USB cables as well as IrDA/®/USB interface converters are available.

The era of analog signal processing is a thing of the past, and digital signal processing will be the trend of the future.

The obvious advantages of SIDSP®

EPK's new technology for in-transducer digital signal processing sets a new standard for innovation in the field of coating thickness measurement. High precision, high reproducibility, insensitivity to temperature changes, and adaptability are the main characteristics of SIDSP®. Innovative production technology combined with an automated calibration process and the ability to calibrate each probe independently results in a high-quality 7400 probe.

This is mainly due to the full use of the advantages offered by SIDSP technology. A good precision production process makes every probe exactly the same.

Reproducibility

The reliability of the readings depends primarily on the reproducibility of the readings. Electromagnetic interference is a common source of error, so it is important to protect the measurement system and probe cables from these interferences.

Unlike conventional techniques, SIDSP® generates and controls the excitation signal inside the probe. The returned signal is directly digitally converted and processed to provide a measured thickness value. The thickness values are digitally transmitted to the display via the probe cable, which means that there are no more interferences in the signal transmission of the analog measuring system in this case. Even if your measuring workpiece requires particularly long cables, the extended cables are also highly resistant to interference.

EPK's SIDSP® probes are extremely reproducible. Put the probe at the same measuring point several times and you get essentially the same result each time, proving once again the performance of the SIDSP® probe.

Production process |

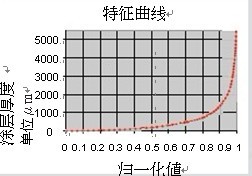

During the production process, SIDSP probes are subjected to a special calibration procedure in which the probes are calibrated at up to 50 points on the characteristic curve, so that the characteristic curve is so accurate over the entire measuring range that deviations can be eliminated. Calibration data is stored in the sensor for a long time and can be retrieved quickly regardless of the SIDSP display it is connected to. In addition, the temperature performance of the probe determines the entire operating temperature range over time. In this way, each probe can be independently adjusted for temperature compensation, maintaining the accuracy of the characteristic curve at any temperature, even with large temperature variations.

Adaptability of the probe

The electrical conductivity of non-ferrous metals may vary. Using automatic compensation for these substrates, the N-type probe or the N-function of the FN-type probe can be used based on the eddy-current principle, which can accurately measure a wide range of non-ferrous materials with different conductivity without the need to calibrate the instrument specifically on the substrate.

All SIDSP® probes are optimally adapted to measure a wide range of sample geometries. Irregularly shaped surfaces can be compensated. When you zero on an uncoated substrate, the entire span is calibrated on this specific shape and material.

Probe design selection

Different cable socket types are more flexible to suit test requirements. Each standard probe is available with a straight cable socket or a right-angle design, the latter of which can measure similar tubes and hollow parts that are difficult to access.

Special probes are required for harsh environments due to paint or dust contamination. For ultimate protection in harsh environments, the MiniTest 7400 offers a specially designed rugged probe series (HD probes). These probes have a special grout seal to protect the probe equipment. The external spring mechanism makes the probe easy to clean.

For rough surfaces, the "F2 HD" probe is particularly suitable for rough surfaces.

ElektroPhysik MiniTest 7400 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Data storage | 250,000 Measured values, 500 groups |

ElektroPhysik MiniTest 7400 Coating Thickness Gauge Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle and Application Analysis of Coating Thickness Gauge

- Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- Analysis of Thickness Measurement Method for Coating Thickness Measurement

- Which Coating Thickness Gauge is Right for You?

- Improvement of Coated Film thickness measurement