DONGRU DR330 Coating Thickness Gauge measurement of metal surface platings

Magnetic Induction and eddy Current dual function, thickness range 0~1250μm, error accuracy +/- 3%, with statistical function, measurement of metal surface coating thickness, can store 116 Measured values.

DongRu

DongRu-

German EPK F05 probe, thickness range 0~500um

$ 1497.00 -

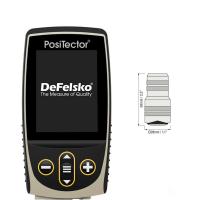

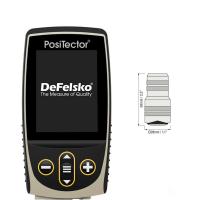

Defelsko PosiTector 6000 NS3 zinc layer thickness Measurement Instrument nonconductive Coating thickness Measurement Instrument

$ 1587.00 -

HUINUO BP-1500FN paints Thickness Gauge, 1500μm thickness measurement integrated dual-use standard type

$ 211.00 -

Defelsko PosiTector 6000 FHXS1 Coating Thickness Gauge, hot surface Coating Thickness Gauge

$ 1684.00 -

IWAVE WH91 split coating Film thickness meter Iron base

$ 182.00

Introduction

Dongru DR330 coating Thickness Gauge is a magnetic/eddy current dual-purpose coating Thickness Gauge designed and developed in strict accordance with the national standard GB/T 8393-1996. The DR330 coating Thickness Gauge is suitable for measuring non-magnetic coatings on magnetic metal substrates. The thickness of the layer and the thickness of the non-conductive coating on the non-magnetic metal substrate is a built-in probe type, which can automatically identify different measurement substrates, and the measurement range is 0~1250 microns. The DR330 coating Thickness Gauge has two test methods, four statistical functions, and two calibration methods, with powerful functions and small size.

Dongru DR330 Coating Thickness Gauge is an all-in-one dual-purpose Thickness Gauge. It is a professional non-destructive testing instrument for measuring the thickness of coated and coated objects on the surface of metal materials according to the national industry: GB/T 8393-1996 standard. It is easy to use, Easy to carry, better repeatability and good performance.

Measurement methods

Dongru DR330 coating Thickness Gauge uses the following different measurement methods according to different metal substrates:

Magnetic thickness measurement method, which can non-destructively measure the thickness of non-magnetic coatings (such as: galvanized, chromium, indium, enamel, rubber, powder, paint, electrophoresis, enamel, anti-corrosion) on magnetic metal substrates (such as: steel, iron) layer, plastic spraying, coating, etc.)

The eddy current thickness measurement method can non-destructively measure the thickness of non-conductive coatings (such as: paint, powder, plastic, rubber, enamel, enamel, electrophoresis, anti-corrosion coating) on non-magnetic metal substrates (such as: aluminum, copper, stainless steel) Thick gauge picture corrosion layer, spray layer, etc.)

Features and advantages

1. Dongru DR330 coating Thickness Gauge provides fast measurement and multiple testing methods

2. Two test methods: continuous test (CONT INUE) and single (SINGLE) measurement method

3. Four statistical functions: maximum value (MAX), minimum value (MIN), average value (MEA), measurement times

4. Can store 116 measurement data

5. It can be connected to a computer for communication and read out the stored data for saving or printing

6. Two calibration methods: zero point calibration and two point calibration

7. Using intelligent measurement, in line with ergonomic design

8. There is a buzzer prompt during the operation (single measurement mode)

9. DR330 coating Thickness Gauge can automatically identify iron-based and non-ferrous-based substrates

10. Low Voltage indication

11. Manual/automatic shutdown function

12. DR330 coating Thickness Gauge has a beautiful appearance and is easy to operate

13. Fine and small integrated design, easy to carry

14. Simple operation and fast test speed

DongRu DR330 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction + eddy Current |

| Measurement range | 0 ~ 1250µm |

| margin of error | ±3% |

| Resolution | 0.1mm | 1mm |

| Minimum radius of curvature | Convex 5mm; Concave 25mm |

| thinnest matrix | 0.4mm |

| probe | F and NF integrated probes |

| Statistical function | Average, MAX Maximum, MIN Minimum, Number of Tests |

| icon function | without |

| Power | 2 * AA alkaline battery |

| Calibrated Certificate | without |

| Language | Chinese |

| Display screen | LCD |

| supporting software | without |

| Total Weight | 99g |

| Complete-built unit size | 102*62*27mm |

| data storage | 116 measurements |

| Operating temperature | 0~50℃ |

| Read speed | Over 50 readings per minute |

| Minimum measurement surface | 10*10mm |

| Relative Humidity | 20~90%RH |

DongRu DR330 Coating Thickness Gauge Packing list

Thickness gauge x1, calibrated diaphragm (50, 100, 250, 370 μm) x4, iron matrix x1, aluminum matrix x1, ABS instrument Encasement box x1, battery x1, manual x1, certificate x1, cleaning cloth x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Introduction of nondestructive thickness testing principle and instrument

- Application Value of Coating Thickness Gauge in Steel Structure Coating Construction

- How to choose a Thickness Gauge?

- Measuring methods of coating Thickness Gauge

- Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- How to choose a suitable painting Thickness Gauge?

- Two Thickness Measurement Methods for Coating Thickness Measurement

- Dry goods | Coating Thickness Gauge working principle and FAQ summary

- Coating Thickness Gauge usage and operation steps

- How to prevent film pores?

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveISO 2178-2016

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveJB/T 7663.2-2007

- ActiveJB/T 5000.12-2007

- ActiveGB/T 8923.1-2011

- ActiveGB/T 1733-1993

- ActiveGB/T 13452.2-2008

DR330

DR330

DR320

DR320