Pushen QTY-32 Bending Tester

Anodic oxidation aluminum material; containing 12 stainless steel shaft rods; shaft bending test; in line with GB/T6740, ISO1519 standards.

Pushen

Pushen-

TRUIT TR 5211 Lacquer Film Cylindrical Bending Tester GB/T 6742 Standard

$ 245.00 -

PUSHEN WZJ-II T-Bend folding machine, film bending performance test

$ 765.00 -

MODERNER WZJ-II Bending machine, testing equipment for measuring the bending resistance performance of color steel plates and Aluminum Panels

Login -

JINGKELIAN QTY-32 cylindrical mandrel bending Tester to determine the ability of the paint film to deform with the substrate without damage

$ 274.00 -

QTZ film cone bending test YONGLIDA film coating cracking performance test

$ 233.00

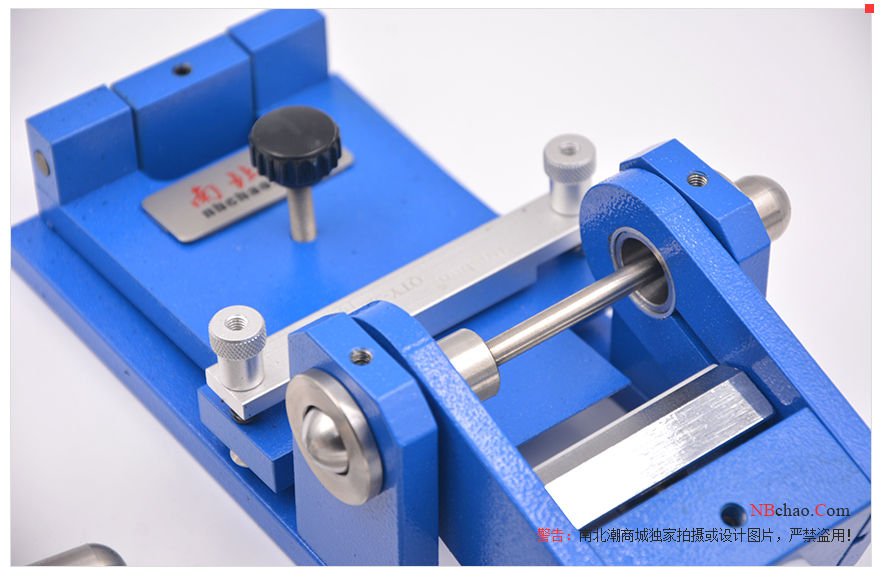

QTY-32 Cylindrical Bending Tester

By bending the coated metal substrate at a set radius, the ductility and adhesion of the paint film under the bending stress can be obtained.

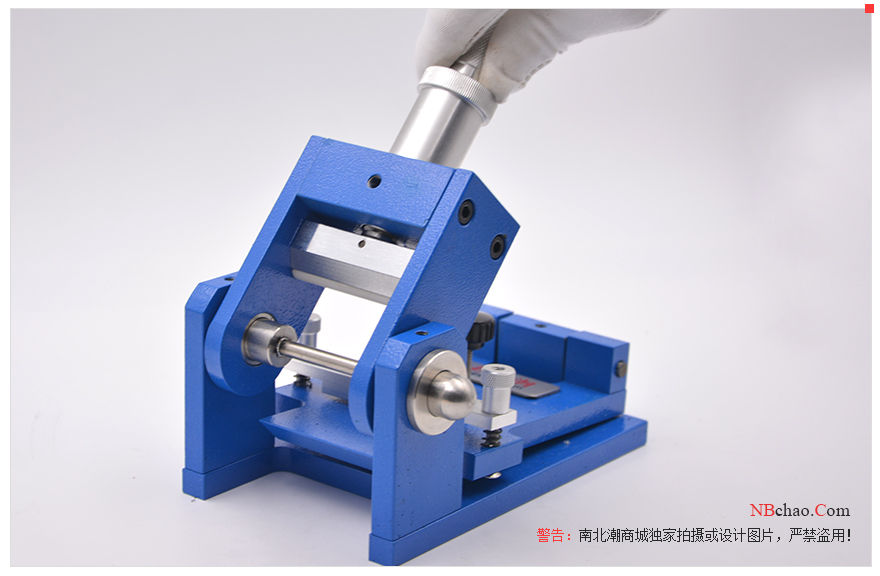

The bend Tester is a simple and quick method to measure the elasticity of the coating. Just bend the coated test panel on a circular shaft of known diameter, and then check the coating for cracking, peeling or other damage.

Made of anodized aluminum

There are 12 stainless steel shaft rods

Test panels up to 50mm wide can be measured

Shaft diameter: 2, 3, 4, 5, 6, 7, 8, 10, 12, 16, 20, 25, 32 mm

Steps

Applying paint to metal substrates

Carefully apply the film and bake it dry to ensure good reproducibility

During the experiment, bend the test substrate to 180° evenly within 1-2 seconds

Starting with the largest diameter mandrel, test in descending diameters until coating breakage is visible

Standards

GB/T 6742-2007 Paints and varnishes bending test - cylindrical shaft

ISO 1519-2011

Pushen QTY-32 Bending TesterSpecifications

| LIST | VALUE |

|---|---|

| Shaft rod size | 2/3/4/5/6/7/8/10/12/16/20/25/32mm |

| Shaft rod material | stainless steel |

| Test board specification | 120×50mm |

| Operation mode | manual |

| Standards | GB/T 6742,ISO 1519 |

| Overall Dimensions | 170*110*230mm |

| Shipment Weight | 7Kg |

Pushen QTY-32 Bending Tester Packing list

Bending tester X1, shaft rod X12, instruction manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Use and Operation Guide of QTY-32 Paint Film Bending Tester

- Correct use of QTY-32 film bending Tester

- Appreciation of several different types of flexibility Testers from Pushen

- Combined pencil Hardness Tester operating instructions

- Shanghai Pushen pushen film preparation instrument selection table [selection]

- Pushen KTQ Micrometer Film Applicator

- A good manual Ink Proofer from domestic (CN)

- ActiveJB/T 3078-2015

- ActiveHG/T 5173-2017

- ActiveSH/T 3022-2019

- ActiveASTM

- ActiveISO FDIS 1519-2010

- ActiveNF

- Active 2099-2013

- ActiveDIN EN ISO 1519-2003

- ActiveNF EN ISO 1519-2002

- ActiveJT/T 821.1-2011

- ActiveDL/T 2308-2021

- ActiveJG/T 224-2007

- ActiveSY/T 4106-2016

- ActiveHG/T 5060-2016

- ActiveHG/T 4338-2012

- Active 0025-2018

- ActiveHG/T 5176-2017

- ActiveHG/T 5059-2016

- ActiveDB 44/T 1106-2012

- ActiveDB 44/T 1024-2012

QTY-32

QTY-32