DONGRU DR370 galvanized Thickness Gauge is simpler for measurement of nonmagnetic metal substrates such as Aluminum Panels

EDDY Current coating thickness measurement, thickness measurement range 0~1250μm, error +/- 3%, black plastic shell, split NF probe, large LCD display, suitable for Aluminum Panel and other nonmagnetic metal substrate measurement.

DongRu

DongRu-

DUBAN DB20-CM211S Split type coating Thickness Gauge, with wire paint film Thickness Gauge

$ 410.00 -

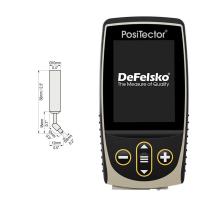

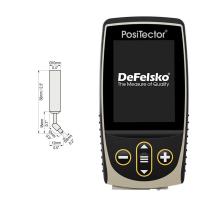

Defelsko PosiTector 6000 F45S1 high-precision Coating Thickness Gauge 45 ° miniature probe

$ 1309.00 -

AMITTARI AC-110A built-in thickness probe with resolution of 0.1 μm

$ 346.00 -

LINSHANG LS226 Coating thickness gauge Iron non-iron dual-use probe 0.0-2000 μm Measurement range

$ 350.00 -

Defelsko PosiTector 6000 F0S1 Eletroplating thickness Measurement Instrument

$ 1309.00

Introduction

Dongru DR370 Coating Thickness Gauge, a black plastic shell, split probe type, eddy current Thickness Gauge using the principle of eddy current thickness measurement. The measurement range of the DR370 coating Thickness Gauge is 0~1250 microns, suitable for use in environments with a temperature of 0~50°C and a humidity range of 20%RH~90%RH. The measurement resolution is 0.1μm/1μm, suitable for The thinnest substrate measured was 0.3mm.

Dongru DR370 Coating Thickness Gauge is a coating Thickness Gauge with a large LCD display, which makes measurement easier and counting more convenient. DR370 coating Thickness Gauge is suitable for measuring non-magnetic metal substrates such as aluminum plates.

Special feature

DR370 coating Thickness Gauge is easy to use, easy to carry, super large LCD, large font size, backlight direct reading is clearer, imported high-quality metal measuring head, precise and firm structure, better repeatability, and excellent performance.

Standards

DR370 Coating Thickness Gauge is an eddy current Thickness Gauge. According to the national industry standard GB/T 4957-1985, the eddy current thickness measurement method is used to measure non-magnetic metal substrates (such as: aluminum, copper, stainless steel) non-destructively. Thickness of conductive coating (such as paint, powder, plastic, rubber, enamel, enamel, electrophoresis, anti-corrosion layer, etc.)

product advantages

Intelligent reminder operation, convenient and accurate:

The aluminum plate coating Thickness Gauge is marked with a buzzer during operation (single measurement mode)

Automatic identification of ferrous and non-ferrous substrates.

Metric and imperial conversion μm/Mil

low Voltage indication

Manual/automatic shutdown function

Beautiful appearance design:

DR370 Coating Thickness Gauge is simple and elegant, portable, exquisite in appearance, fine in workmanship and accurate in measurement

Fully intelligent touch buttons, non-slip type, unique design, novelty, user-friendly, compact structure, professional technology

Imported high-quality metal measuring head is adopted, with more stable performance, wear resistance and pressure resistance, and long service life

Simple and readable test operation:

Large LCD display, backlight, large font size display, highly clear and accurate readings from any angle

The test speed is fast, the sensitivity is high, and the stability is good.

Two modes of continuous test and single measurement are optional; continuous test can effectively reduce human error and make the measured value more accurate.

The DR370 coating Thickness Gauge can count the maximum value, minimum value, average value, and measurement times. It can be completed with one key, good, effective, convenient and large-capacity storage, can store more than 800 measurement data, connect to the computer to read the data and print and save .

Two calibration methods can be used: zero-point calibration and two-point calibration, two-point calibration is more accurate.

Still worrying about measuring coating thickness, this coating Thickness Gauge can meet your needs!

DongRu DR370 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Eddy Current |

| Measurement range | 0 ~ 1250µm |

| margin of error | ±3% |

| Resolution | 0.1mm | 1mm |

| Minimum radius of curvature | Convex 5mm; Concave 25mm |

| thinnest matrix | 0.3mm |

| probe | NF Split Probe |

| Statistical function | Average, MAX Maximum, MIN Minimum, Number of Tests |

| icon function | without |

| Power | 3 * AAA alkaline battery |

| Calibrated Certificate | without |

| Language | Chinese |

| Display screen | LCD |

| supporting software | without |

| Total Weight | 100g |

| Complete-built unit size | 130*70*24mm |

| Operating temperature | 0~50℃ |

| Minimum measurement surface | 10*8mm |

| Relative Humidity | 20~90%RH |

DongRu DR370 Coating Thickness Gauge Packing list

Thickness gauge x1, calibrated diaphragm (50, 100, 250, 370 μm) x4, aluminum matrix x1, ABS instrument Encasement box x1, battery x1, manual x1, certificate x1, cleaning cloth x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Application of Ultrasonic Thickness Gauge in Spinning Tube Abrasion Monitoring

- Introduction of nondestructive thickness testing principle and instrument

- Correct use of Film Thickness Gauge

- Influencing factors of ultrasonic thickness indication distortion

- Application Value of Coating Thickness Gauge in Steel Structure Coating Construction

- How to choose a Thickness Gauge?

- Measuring methods of coating Thickness Gauge

- Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- How to choose a suitable painting Thickness Gauge?

- Galvanizing problem

- ActiveGB/T 44757-2024

- ActiveJB/T 13939-2020

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveASTM B244-2021

- ActiveISO 2360-2017

- ActiveASTM D7091-2022

- ASTM E376-2019

- ActiveGB/T 17456.1-2009

- ActiveGB/T 13452.2-2008

- ActiveGB/T 11374-2012

- ActiveGB/T 4957-2003

DR370

DR370