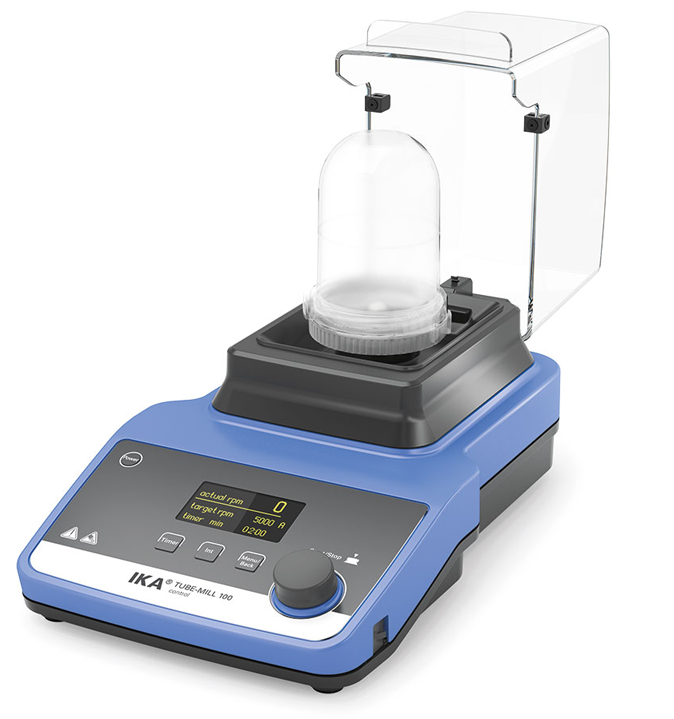

Germany IKA Tube Mill 100 control Grinder

The German IKA TubeMill100 controlled testtube Grinder is a batch processing Grinder that uses disposable grinding cups, and the ubeMill100 has a larger grinding cup with a maximum volume of 100 ml (MT100).

IKA

IKA-

HUXI HM5-2 Sample Homogenizer, Capacity 2 × 5ml

$ 1808.00 -

HUXI HMD-400 multifunctional freezing grinding instrument 6 holes × 5ml round PTFE adapter

$ 5488.00 -

Muxuan MXY-C4000-40 Lab Basket Grinder 4000W/40L

$ 3426.00 -

HUXI HMR-1 Handheld grinding instrument φ 4mm pestle

$ 132.00 -

HUXI HMD-400 multifunctional freezing grinding instrument 6 holes × 2ml round PTFE adapter

$ 5488.00

Introduction

The Tube Mill 100 is a batch Grinder that uses disposable grinding cups. Single-use grinding cups eliminate the possibility of cross-contamination and save on cleaning costs.

The Tube Mill 100 controlled tube Grinder has a larger grinding cup with a maximum volume of 100 ml (MT 100).

The grinding cup and top lid are made of transparent material, so the user can see the grinding process at any time. Used for grinding hard (with a maximum processing hardness of 5Mohs), dry and brittle materials. It is especially suitable for grinding seeds, such as corn and wheat.

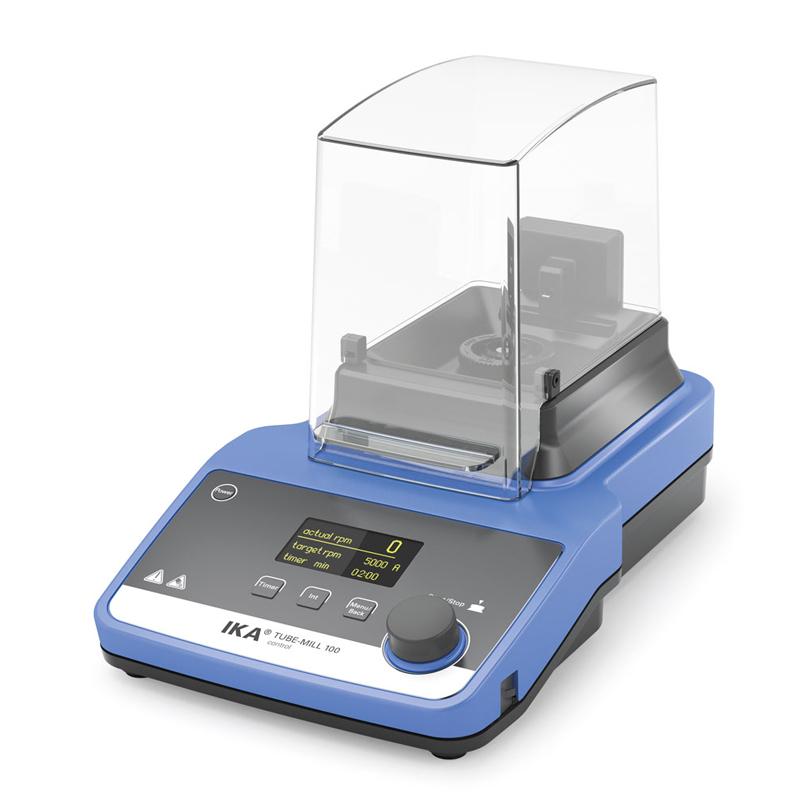

The Grinder will only start running when the protective cover is closed, which is safe and reliable.

Features

Clear, multi-language OLED LCD display (including error code display)

Timer function with a Timer Range of 5 s - 3 min

USB interface (to control and record all data)

Intermittent operation is possible

Infinitely variable speed (5000 to 25,000 rpm)

A variety of operating modes are available

Adjustable safety speed and time

Programmable and storable test conditions

Reproducible test results

Touch buttons

Grinding cups included in the delivery: 1 x MT 40, 1 x MT 100 and 1 x MMT 40

IKA Tube Mill 100 control GrinderSpecifications

| LIST | VALUE |

|---|---|

| Motor Power | 80W |

| Speed regulation range | 5000 ~ 25000 rpm |

| Effective Volume of sand grinding basket | 100ml |

| Dimension | 180*212*300 mm |

| Power supply Voltage | 220 - 240 / 100 - 120 / 100 V |

| Weight | 2.8 kg |

| Process type | batch processing |

| Working principle | Shear/Impact |

| Motor Input Power | 100W |

| Velocity deviation | 2 ±% |

| Maximum Feed Hardness | 5Mohs |

| Maximum feed particle | 10mm |

| Impact/shear cutter head material | Stainless steel 1.4034 |

| Grinding chamber material | Stainless steel 1.4301 |

| material | PTFE |

| Working time | 3min |

| Grinding materials can be chilled down with dry ice in the grinding chamber | Yes |

| Environmental temperature | 5 - 40 ℃ |

| Allowable Relative Humidity | 80 % |

| Type of protection | IP 30 |

| USB port | Yes |

| Frequency | 50/60 Hz |

| Input Power | 100 W |

| Maximum circumferential velocity | 65 m/s |

IKA Tube Mill 100 control Grinder Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- What factors affect the low dispersion efficiency of the Grinder?

- Production process of coating powder

- List of ASTM Coatings and Coating-related Standards

- Practical examples of water-bomecoating varnishing performance and tinctorial strength

- IKA A11 Grinder steps to use

- Taber ® Abra sers: Applicable Wear and Related Test Methods

- Modified Calcium Ash Powder Technology Coating Production Process

- Preparation method of water-resistant putty powder

- Current Situation and Development of Basket Grinder

- Four Steps to Effective Pigment Dispersion

Tube Mill 100 control

Tube Mill 100 control