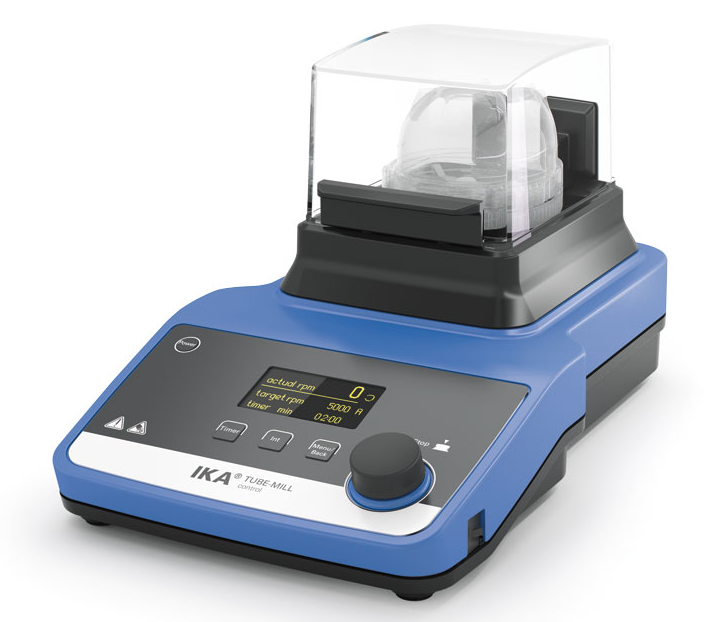

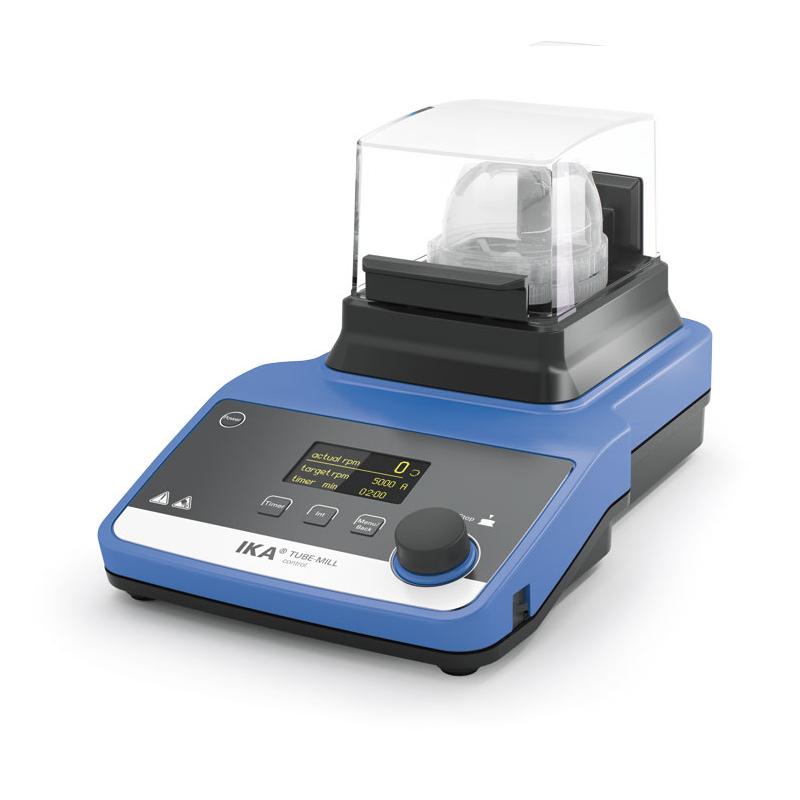

German IKA Tube Mill control Grinder

The German IKA Tube Mill controlled testtube Grinder is a batch processing Grinder that uses disposable grinding cups, and the Tube Mill can be used to grind hard (maximum processing Hardness of 5Mohs), dry and brittle samples.

IKA

IKA-

HUXI HX-PC2L Tissue Masher 2L/500W

$ 214.00 -

HUXI LSYM-3L Experimental Vertical Grinder

$ 1016.00 -

HUXI HMD-400 Multifunctional freezing grinding instrument, double tank grinding

$ 5124.00 -

HUXI HMD-400 Multifunctional freezing grinding instrument 30 holes × 0.5ml Cube PTFE adapter

$ 5542.00 -

MODERNER SFJ-400 Sanding, Dispersion, Stir Multi-purpose Machine (Variable Frequency Speed Regulation) for Chemical Laboratories

Login

Introduction

The IKA® Tube Mill is a batch Grinder that uses disposable grinding cups. Single-use grinding cups eliminate the possibility of cross-contamination and save cleaning costs and time. The grinding cup and top lid are made of transparent material, so the user can see the grinding process at any time. It can be used to grind hard (maximum processing hardness of 5Mohs), dry and brittle samples. Ideal for grinding seed samples such as corn and wheat. During the development process, the developers paid special attention to the user safety of this test tube Grinder! The Grinder will only start running with the protective cover closed. If the grinding cup is not installed or closed correctly, the main machine displays an error message and the Grinder does not start running. The grinding cup cannot be opened during the grinding process. A curved ring seal between the motor and the grinding cup prevents dust from flying out of the grinding cup or into the motor.

Features

Clear, multi-language OLED LCD display

Timer: The Timer Range is 5 s - 3 min

USB interface for remote control and data logging

Intermittent operation is possible

Infinitely variable speed range from 5000 to 25,000 rpm

A variety of operating modes are available

Adjustable safety speed

Adjustable safety time

Programmable and storable of test conditions

Error code display function

Reproducible test results

The touch buttons are easy to operate

Hermetically sealed dustproof housing

Runs silently

IKA Tube Mill control GrinderSpecifications

| LIST | VALUE |

|---|---|

| Motor Power | 80W |

| Speed regulation range | 5000 ~ 25000 rpm |

| Effective Volume of sand grinding basket | 40 ml |

| Dimension | 180*170*300 mm |

| Power supply Voltage | 220 - 240 / 100 - 120 |

| Weight | 2.7 kg |

| Process type | batch processing |

| Working principle | Shear/Impact |

| Motor Input Power | 100W |

| Velocity deviation | 2 ±% |

| Maximum Feed Hardness | 5Mohs |

| Maximum feed particle | 10mm |

| Impact/shear cutter head material | Stainless steel 1.4034 |

| Grinding chamber material | Stainless steel 1.4301 |

| material | PTFE |

| Working time | 3min |

| Grinding materials can be chilled down with dry ice in the grinding chamber | Yes |

| Environmental temperature | 5 - 40 ℃ |

| Allowable Relative Humidity | 80 % |

| Type of protection | IP 30 |

| USB port | Yes |

| Frequency | 50/60 Hz |

| Input Power | 100 W |

| Maximum circumferential velocity | 65 m/s |

IKA Tube Mill control Grinder Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- What factors affect the low dispersion efficiency of the Grinder?

- Production process of coating powder

- Effect of Ground Conditions on Dispersion of UV Ink-jet Printing ink

- Production technology of styrene-acrylic interior wall engineering paint

- Four Steps to Effective Pigment Dispersion

- Current Situation and Development of Basket Grinder

- Advantages of coating powder and its production process

- Modified Calcium Ash Powder Technology Coating Production Process

- Preparation method of water-resistant putty powder

- Water-based paint production process

Tube Mill control

Tube Mill control