Japan OSP S-16 wire brush Wire diameter 0.06mm

The diameter of the steel wire is 0.06mm, the number of rows is 4, there are 62 acupoints, the thickness of the pedestal is 10mm, the width of the pedestal is 17mm, and the length of the pedestal is 235mm.

OSP

OSP-

TRUIT TR 3501/A3 Bakelite Glass film table 460 * 270mm

$ 214.00 -

Japan OSP K-16 wire cleaning brush, wire length 16mm 6 lines

$ 143.00 -

Japan OSP L250 Spreader handle, with OSP L250 series Applicator rod

$ 99.00 -

TRUIT TR 3501/2 Glass Applicator 240 * 160 * 8mm

$ 100.00 -

Japan OSP M-16 wire brush wire length 16mm without hand grip part

$ 143.00

Introduction

Japan OSP wire brush S-16 is used for laboratory cleaning of wire rods and production of anilox rollers. The wire brush is made of stainless steel wire with a Wire diameter of 0.06mm. The length of the bristles of S-16 is 16mm. The base of the S-16 wire brush is wooden.

main application

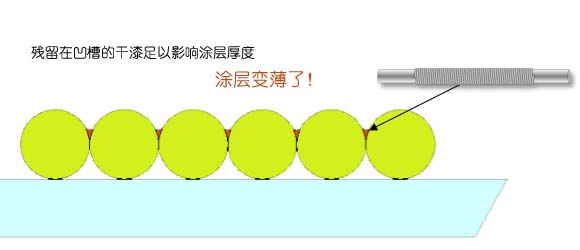

The anilox roller wire brush is used to clean the anilox roller, suitable for cleaning the anilox roller of the production machine, cleaning the laboratory coating wire rod, etc. The cleaning effect of the anilox roller wire brush is effective, and it does not damage the instrument

Features

1. The stainless steel brush (anilox roller wire brush) sold on the market at present has the smallest Wire diameter of 0.07mm, and the Wire diameter of this anilox roller wire brush is only 0.06mm! Because it is fine, it can be cleaned more effectively.

2. Because the diameter of the steel wire is only 0.06mm, the bristles are super soft, which will not damage the roller surface while cleaning.

3. The anilox roller wire brush is produced in Japan. Each one is handmade by artisans with years of experience.

Instructions

1) After shutting down, first wash off the ink on the surface of the wire Bar Coater with clean water.

2) Spread the cleaning liquid directly on the surface of the anilox roller evenly, wait for about ten minutes, and then use the anilox roller wire brush to scrub the wire Bar Coater in a circular motion for 3 to 5 minutes, during which the cleaning liquid will produce some foam. After brushing, let the foam stay on the surface of the anilox roller for 3 to 5 minutes.

3) Finally, rinse off the cleaning solution with clean water. Pay attention to cleaning, do not leave cleaning fluid on the surface of the anilox roller.

4) If the wire Bar Coater is seriously blocked: Prolong the residence time of the cleaning solution and the brushing time, or repeat the above steps.

OSP S-16 Stainless steel brushSpecifications

| LIST | VALUE |

|---|---|

| Wire diameter | 0.06mm |

| number of rows | 4 lines |

| acupuncture point | 62 |

| Film thickness | 10mm |

| pedestal width | 17mm |

| Pedestal length | 235mm |

| Bristle part width | 12mm |

| Bristle part length | 75mm |

| Bristle length | 16mm |

OSP S-16 Stainless steel brush Packing list

Wire brush X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- The experimental case of OSP Mayer Rods at inks Moulding [with video]

- What problems should I pay attention to when buying a wire rod applicator?

- Nanbei Chao technical engineer tells you: What are often asked when buying a wire rod?

- Frequently Asked Questions for Inventory 2022 Lines, Issue 1

- What wire rod applicator have users in the aluminum profile industry bought?

- Preparation of Ultrafine Silver Nanowire Transparent Conductive Films by Coating Machine + Wire Rod

- What kind of bar applicator have customers in the adhesive industry bought?

- Preparation of fluorescent anti-counterfeiting gravure ink with ink proofing machine

- What are the models of popular bar applicators?

- Which wire rod applicators have the printing industry purchased?

S-16

S-16

M-16

M-16

K-16

K-16

S-8

S-8