LEEB270 high-precision Coating Thickness Gauge magnetic Induction probe replaceable

LEEB270 high-precision Coating Thickness Gauge uses a magnetic thickness measurement method for nondestructive measurement of the thickness of nonmagnetic coatings (e.g. zinc, aluminum, chromium, copper, rubber, paints, etc.) on magnetic metal substrates (e.g. steel, iron, alloy and hard magnetic steel, etc.); the probe can be replaced

-

LANDTEK CM8829n paint Thickness Gauge, integrated eddy current paint Thickness Gauge

$ 313.00 -

German EPK MiniTest 600 B-FN coated platings Thickness Gauge, iron-based/non-iron-based

Login -

Defelsko PosiTector 6000 Advanced Coating Thickness Gauge host, probe purchased separately

$ 946.00 -

Defelsko F45S split 45 ° micro probe

$ 1049.00 -

Defelsko FS conventional strip probe 0~1500μm/non-ferrous metal

$ 703.00

High Precision Coating Thickness Gauge LEEB270It is possible to measure coatings and plating quickly, without damage, and with precision. It can be used both in the laboratory and in the engineering field. By adapting to different probes, a wide range of measurement needs can also be accommodated. This instrument is widely used in manufacturing, metal processing industry, chemical industry, commodity inspection and other testing fields. It is an instrument required for the material protection profession. This instrument conforms to the following standards: GB/T 4956-1985 Thickness Measurement of Non-magnetic Cladding on Magnetic Metal Matrix, Magnetic Method, JB/T 8393-1996 Magnetic Cladding Thickness Gauge JJG 889-95

Features

● Full Chinese menu interface operation, simple and convenient;

● This instrument adopts the magnetic thickness measurement method, which can non-destructively measure magnetic metal substrates (such as steel, iron, alloy and

Thickness of non-magnetic overlay (e.g., zinc, aluminum, chromium, copper, rubber, paint, etc.) on hard magnetic steel, etc.

● There are two measurement methods: continuous measurement mode (CONTINUE) and single measurement mode (SINGLE);

● It has two Operating Modes: direct mode (DIRECT) and group mode (A-B);

● There are five statistics: MEAN, MAX, MIN, NO.,

standard deviation (S.DEV);

●A variety of calibration methods: the instrument is basically calibrated, and the systematic error of the instrument can be corrected by using five test pieces calibration;

● With storage function: it can store 4 types of workpieces, 26 groups of each type of workpiece, 15 measured values in each group, a total of 1560 measured values;

● It has the function of deleting: deleting a single suspicious data that appears in the measurement, and also deleting all the data in the storage area in order to carry out new measurements;

● Set the limit: the measured value outside the limit can be automatically alarmed;

● There is a beep prompt during the operation;

● High-brightness LED backlight display, which is convenient for use in dark environments.

● There are two shutdown modes: manual shutdown mode and automatic shutdown mode

Leeb leeb270 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction |

| Measurement range | 0~1250μm |

| margin of error | ±3% |

| Resolution | 0.1μm |

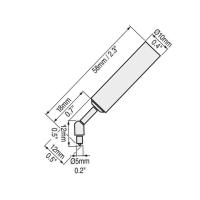

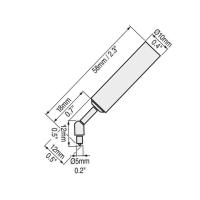

| Minimum measurement surface | Φ7mm |

| Minimum radius of curvature | Convex 1.5mm, Concave 9mm |

| thinnest substrate | 0.5mm |

| probe | Fe |

| Measurement mode | Continuous Measurement mode (CONTINUE) and Single Measurement mode (SINGLE) |

| statistical function | Measurement times, MAX Maximum, MIN Minimum, Average, Standard deviation |

| Data storage | 1560 Measured values |

| Power Supply | 2*1.5V |

| Display screen | black and white |

| Operating temperature | 0~40℃ |

| Relative Humidity | 20~90%RH |

| Machine Weight | 200g |

| Machine size | 163*78*33mm |

Leeb leeb270 Coating Thickness Gauge Packing list

host, standard test piece, substrate, 4 AA batteries, documents, instrument case

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

Leeb

Leeb leeb270

leeb270

leeb260

leeb260

leeb261

leeb261