LANDTEK CM8820 Coating Thickness Gauge paints Film Thickness Gauge

Magnetic Induction Thickness Measurement Principle, Thickness Measurement Range 0~2000μm, Accuracy Error +/- 5%, F Split Probe, for measurement of the thickness of non-magnetic conductive coatings on ferromagnetic metal substrates, no supporting software.

LANDTEK

LANDTEK-

LANDTEK CM8856 Surface platings Thickness Gauge F magnetic Induction /NF eddy current split platings Thickness Gauge

$ 496.00 -

Defelsko FNTS thick coating probe 0~6mm/+/- 1%

$ 1328.00 -

ERICHSEN PIG455 Film Thickness Gauge

$ 1492.00 -

German EPK MiniTest 600 B-F magnetic platings Thickness Gauge, thickness: 0~3000μm

$ 912.00 -

LINSHANG LS230 Film Thickness Gauge OLED single screen, low temperature resistance

$ 171.00

Introduction

CM8820 coating Thickness Gauge adopts magnetic induction measurement method, and the measurement range is 0~2000μm (0~5mm is customized for large range). CM8820 coating Thickness Gauge uses a magnetic sensor to measure non-ferromagnetic coatings and coatings on ferromagnetic metal substrates such as steel and iron, such as: paint, powder, plastic, rubber, synthetic materials, phosphating layer, chromium, zinc, Lead, aluminum, tin, cadmium, porcelain, enamel, oxide layer, etc.

Note: CM8820 coating Thickness Gauge can customize different measurement ranges (2mm-6mm) according to the user's measurement range requirements, please consult the mall engineer for details.

Application

Coating Thickness Gauge CM-8820 uses a magnetic sensor to measure non-ferromagnetic coatings and coatings on ferromagnetic metal substrates such as steel and iron, such as: paint, powder, plastic, rubber, synthetic materials, phosphating layer, chromium, Zinc, lead, aluminum, tin, cadmium, porcelain, enamel, oxide layer, etc.

Features

Measuring the thickness of non-magnetically permeable coatings on ferromagnetic metal substrates

Pictures

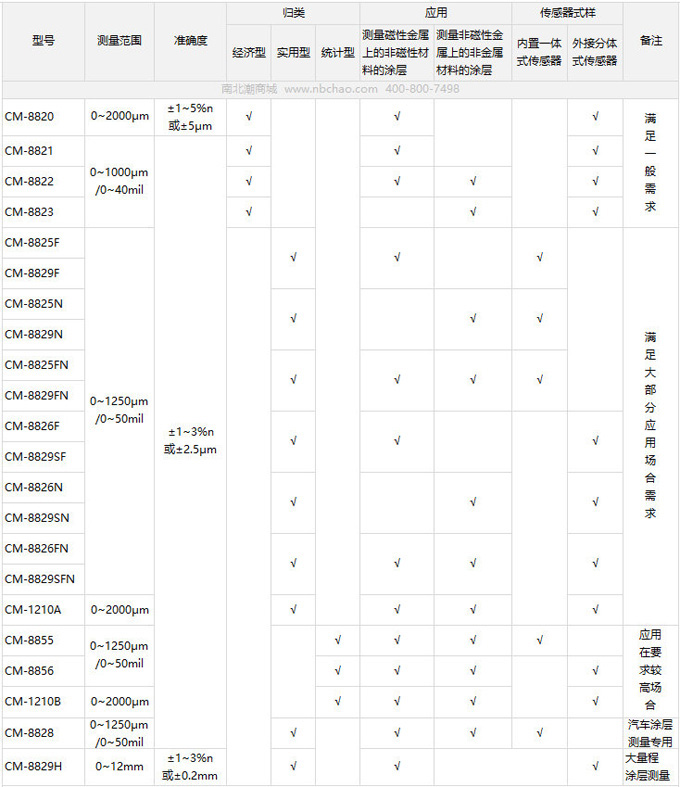

LANDTEK Coating Thickness Gauge Selection List

LANDTEK CM8820 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | magnetic induction |

| Measuring range | 0 ~ 2000m |

| margin of error | ±5% |

| resolution | 0.1mm | 1mm |

| Minimum radius of curvature | F: convex 1.5mm; concave 25mm |

| thinnest matrix | 0.3mm |

| probe | F Split Probe |

| Power | 4 * AA battery |

| Calibrated Certificate | without |

| Language | Chinese |

| Display screen | LCD |

| supporting software | without |

| Total Weight | 210G (without battery) |

| Complete-built unit size | 161*69*32mm |

| Minimum measurement surface | F6mm |

| Unit display | μm/mils |

| Voltage prompt | Low Voltage prompt |

| Operating Temperature | 0~40℃ |

| Relative Humidity | 10~90%RH |

LANDTEK CM8820 Coating Thickness Gauge Packing list

Host x1, measurement probe x1, reference block (iron base) CTG-BSx1, calibrated diaphragm CTG-CFx4, portable box x1, manual x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Lantai CM8820, CM8821, CM8822 and CM8823 Coating Thickness Gauge [Parameter comparison]

- Difference and comparison of Lantai Thickness Gauge CM8822, CM8821 and CM8820

- CM-8822 Landtek Coating Thickness Gauge

- Comparison table of each model of LANDTEK Thickness Gauge [Selection Guide]

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveGB/T 42541-2023

- ActiveGB/T 7991.5-2014

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveISO 2178-2016

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveGB/T 12334-2001

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- ActiveGB/T 9274-1988

CM8820

CM8820

CM8820 (5mm range)

CM8820 (5mm range)