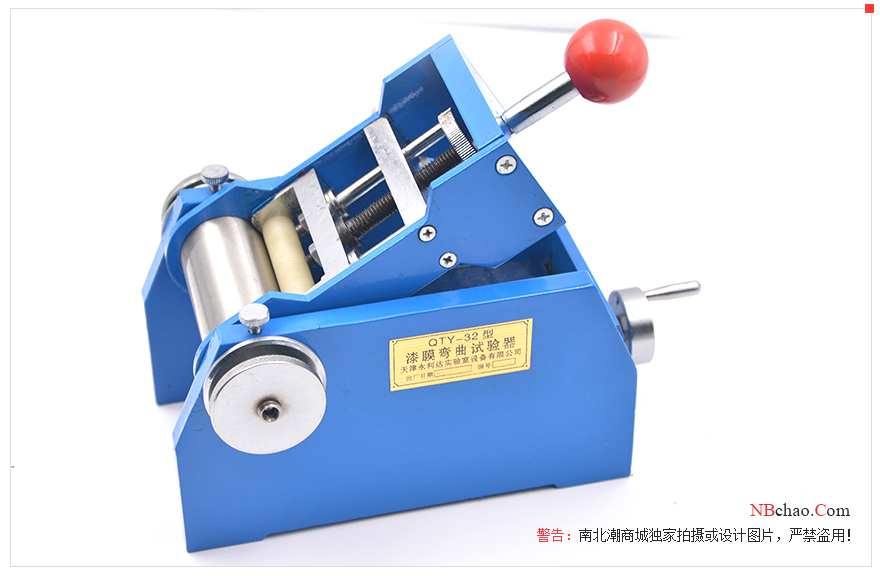

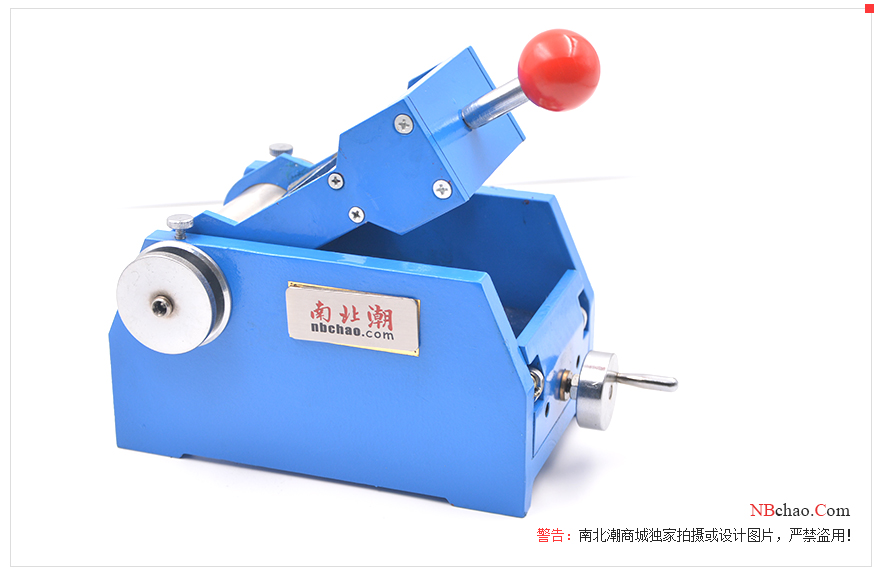

QTY-32 Lacquer film cylindrical Bending Tester YONGLIDA maximum shaft rod diameter 32mm

Cylinder mandrel bending test; standard 13 different diameters of the shaft bar; test plate substrate thickness requirements ≤ 1.0mm; in line with GB/T6742, ISO1519, ASTM/D522, DIN 53152 standards.

YongLiDa

YongLiDa-

Test grade tinplate 300 * 400 * 0.28 right angle, experimental special tinplate

$ 192.00 -

Test grade tinplate 300 * 400 * 0.4 right angle, experimental special tinplate

$ 222.00 -

Test grade tinplate 50 * 120 * 0.28 rounded corners, experimental special tinplate

$ 157.00 -

Test grade tinplate 50 * 120 * 0.4 rounded corners, experimental special tinplate

$ 173.00 -

Test-grade tinplate sheet 100 * 200 * 0.28 rounded corners, experimental special tinplate sheet

$ 226.00

1. Application

QTY-32 paint film bending Tester is mainly suitable for measuring the film flexibility of paints and varnishes.

QTY-32 paint film bending Tester is a special instrument for evaluating the performance of cracking or peeling off metal plates of paints, varnishes and related products when they are bent around a cylindrical axis under standard conditions. It complies with GB6742 and ISO1519 standards.

2. Structural principles and main parameters

1. Principle

The ductility of the coating film to the substrate is different with different bending radii. The flexibility of the coating film is judged according to the cracking or peeling of the coating film at different bending radii.

The diameters of the shafts of the QTY-32 paint film bending Tester are 2, 3, 4, 5, 6, 8, 10, 12, 14, 18, 20, 25, and 32 mm.

The adjustment amount of the rotating handle should be greater than 17mm, and the allowable gap is 0.05mm when it is close to the test rod.

The lifting amount of the support plate parts should be greater than 17mm, and the allowable gap is 0.1mm when it is close to the test rod.

This instrument is suitable for samples with a thickness below 1.Omm.

3. Use and operation

1. Sampling, coating, drying and thickness measurement according to product standard requirements.

2. Place the QTY-32 paint film bending Tester against the edge of the test bench so that the adjustment handle can be operated freely and inserted into the sample.

3. Select a suitable shaft rod according to the product requirements. Insert it into the base of the Tester and the shaft hole, and tighten it with a manual nut.

Display of QTY-32 Paint Film Cylindrical Bending Tester

YongLiDa QTY-32 Lacquer film cylindrical mandrel bending TesterSpecifications

| LIST | VALUE |

|---|---|

| Shaft rod size | 2/3/4/5/6/8/10/12/16/18/20/25/32mm |

| Film thickness | ≤ 1.0mm (tinplate) |

| Standards | GB/T6742-86,ISO1519-73,ASIMD522,DIN53152 |

| Standards | GB6742,ISO1519 |

YongLiDa QTY-32 Lacquer film cylindrical mandrel bending Tester Packing list

host X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- What factors affect the flexibility of the coating?

- Purpose, characteristics, operation steps and precautions of cone bending testing machine

- Detailed explanation of 3 methods for measuring film flexibility

- Determination of film flexibility and its application in GB/T 1731 standard

- Working principle and application analysis of platings Bending Tester

- ActiveJB/T 3078-2015

- ActiveHG/T 5173-2017

- ActiveSH/T 3022-2019

- ActiveASTM

- ActiveISO FDIS 1519-2010

- ActiveNF

- Active 2099-2013

- ActiveDIN EN ISO 1519-2003

- ActiveNF EN ISO 1519-2002

- ActiveJT/T 821.1-2011

- ActiveDL/T 2308-2021

- ActiveJG/T 224-2007

- ActiveSY/T 4106-2016

- ActiveHG/T 5060-2016

- ActiveHG/T 4338-2012

- Active 0025-2018

- ActiveHG/T 5176-2017

- ActiveHG/T 5059-2016

- ActiveDB 44/T 1106-2012

- ActiveDB 44/T 1024-2012

QTY-32

QTY-32

QTY-10A

QTY-10A