Qnix 5500 magnetic Induction Coating Thickness Gauge split 3mm

Split magnetic Induction probe, testing nonmagnetic Coating thickness on magnetic metal substrate, range 0~3000μm, wear-resistant ruby probe, one-button operation without calibrating.

Qnix

Qnix-

Dual-use Coating Thickness Gauge AMITTARI AC-110AS External thickness probe type, thickness range 0~1250um

$ 346.00 -

AMITTARI USB data cable, which can be connected to most AMITTARI series test instruments through the RS-232 software system

$ 110.00 -

PHYNIX Surfix SX-N1.5 non-ferrous paints Thickness Gauge 1500μm

Login -

List MEGA-CHEK Master Storage Fast Scan Platings Thickness Gauge

$ 2156.00 -

LANDTEK Thickness Gauge probe 90 ° right angle iron based probe

$ 163.00

The QNix 5500 Coating Thickness Gauge is a convenient, durable, and action-friendly instrument for:Modular version, the user can decide which probe to use and the cable. Just in case, remember to disconnect the power supply when replacing the probe!

Whether it's in industrial painting, task testing, corrosion protection or vehicle evaluation, the QNix5500 is designed to provide the fastest and most convenient way to measure coating thickness by simply turning on the machine and placing the instrument on the surface of the workpiece to obtain measurement data, without the need for a series of setup operations.

The large 2-inch color LCD with auto-flip makes it easier to read the measured values in any position, even in harsh lighting conditions. Such as bridge cavities and Water Tanks, or when working outdoors or in strong sunlight. The QNix5500 provides all the necessary statistical information about the current measurement series: the display of the mean, standard deviation, maximum and minimum measurements.

The proper design ensures safe contact and avoids erroneous measurements. For smaller contact areas or inclined components, simply use the probe cable and plug the QNix®5500 into the cable device for a few seconds (only available for the modular version). The angled cable connection makes it easier to work comfortably even when space is limited.

With one-button operation, you can reliably and quickly zero the workpiece on the substrate or on the supplied zero plate.

The right probe for every application – precise, with high accuracy over the entire measuring range: measuring ranges from 1.25 mm to 3 mm to 5 mm, Fe, NFe or dual probes can be used.

Qnix QNix5500+Fe3mm Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction |

| Measurement range | 0~3000μm |

| margin of error | ±2~3% |

| Minimum measurement surface | Φ14.5mm |

| Minimum radius of curvature | R6mm |

| thinnest substrate | 0.2mm |

| probe | Line probe |

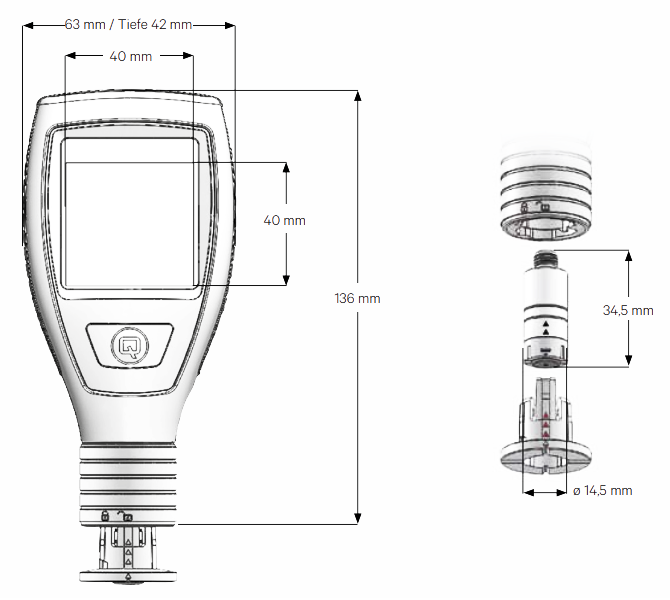

| Probe size | Φ14.5*34.5mm |

| Probe material | Shell top stainless steel (1.4305); Shell bottom Trogramid ® (CX7323) |

| Probe Weight | 11.9g |

| Unit display | μm |

| statistical function | MAX Maximum, MIN Minimum, Average, Standard deviation |

| Power Supply | 2 * 1.5V (AA) alkaline battery |

| Standards | DIN EN ISO 2808,DIN 50981,DIN 50984,ISO 2178, BS 5411(3&11),BS 3900-C5,ASTM B 499,ISO 2360, ASTM D 1400,ASTM D 1186,ASTM D 7091 |

| Display screen | IPS-LCD, 2-inch, color, 350cd/m2, with a Viewing Angle of 70 ° in all directions. |

| Operating temperature | -20℃-70℃ |

| Battery life | 1 year (1 measurement per second) |

| Protection level | IP65 |

| Shell material | Hard fiberglass * PA12 GF30 |

| Machine Weight | 132g |

| Machine size | 136* 63*42mm |

| Storage temperature | -20~70℃ |

| Maximum workpiece surface temperature for continuous measurement | 80℃ |

| Battery life | > 2 years |

Qnix QNix5500+Fe3mm Coating Thickness Gauge Packing list

QNix5500 host, 1 Fe zero adjustment board each, 1 standard piece, factory test report, instruction manual, 2 1.5V AA alkaline batteries, plastic instrument case

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle, Application and Type Selection of Electronic Coating Thickness Gauge

- How to choose a suitable painting Thickness Gauge?

- Coating Thickness Gauge for coated Film thickness measurement in vehicle evaluation

- Which Coating Thickness Gauge is Right for You?

- Concept and basic knowledge of coating Thickness Gauge

- Why Use Coating Thickness Gauges in Powder Coatings?

- What is a metal substrate? How does it affect coating thickness measurements?

- Three precautions for the use of paint film coating Thickness Gauges

- Two Thickness Measurement Methods for Coating Thickness Measurement

- How does the QNix Coating Thickness Gauge maintain accuracy?

- ActiveQJ 990.3A-2011

- ActiveGB/T 42541-2023

- ActiveGB/T 7991.5-2014

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveSY/T 0315-2013

- ActiveGB/T 4956-2003

- AbolishGB/T 4956-1985

- ActiveQB/T 2183-1995

- ActiveJB/T 7217-2008

- ActiveJB/T 7663.2-2007

- ActiveGB/T 8923.1-2011

- ActiveGB/T 1733-1993

- ActiveGB/T 11374-2012

QNix5500+Fe3mm

QNix5500+Fe3mm