QNix 9500Pro Cladding Thickness Gauge magnetic Induction/eddy Current 3000μm

Enhanced 9500 Thickness Gauge, built-in dual-function probe, thickness measurement range of 0~3000 microns, error +/- 2%/3%, can be used for anti-corrosion coatings lame plating thickness measurement monitoring, the display screen can be flipped display, suitable for curved surfaces and small workpieces.

Qnix

Qnix-

LANDTEK CM8829F magnetic Film Thickness Gauge, one-piece, thickness range 0~3mm

$ 451.00 -

List Magnetik Pocket TOP-CHECK FE-B Pocket platings Thickness Gauge

$ 1524.00 -

LANDTEK CM8829F magnetic Thickness Gauge, integrated F magnetic Induction Film Thickness Gauge

$ 313.00 -

Defelsko PosiTector 6000 FT1 Portable platings Thickness Gauge, integrated magnetic Thickness Gauge

$ 1000.00 -

Defelsko PosiTector 6000 N1 film thickness Measurement Instrument nonconductive coating Measurement Instrument

$ 957.00

QNix9500, rugged, user-friendly interface, reliable quality, multi-purpose and high precision.

QNix9500 has considerable characteristics for the quality control of product production in the process of industrial anti-corrosion, spraying, and surface treatment, whether in compliance with standards or technical parameters. The newly developed QNix9500 PC software enables faster and more efficient management of documentation and inspection reports than ever before. Every QNix9500 is manufactured entirely in Germany.

Compared with the basic type Thickness Gauge, the enhanced Thickness Gauge adds independent and independent calibration in terms of calibration, with 10 groups of calibration value memory function, continuous measurement mode and pin code protection function. In addition, the measurement can be triggered by pressing a button, and the probe can be placed on the surface of the workpiece for a delayed measurement.

Features

1. High-precision measurementEnsure that the quality results are effective

• High-precision measurement in the full range

• High repeatability of measurement results

• Temperature compensation in the probe

• Guaranteed measurement accuracy on curved surfaces and small workpieces

• Easy indexing on rough, smooth, and curved substrates

2. Solid and durable protectionLong-term use under the conditions of satisfying the evil strategy

• Fiberglass included, consisting of 5 components in accordance with IP64

• Waterproof and light-proof

• Three layers of shock protection

• LCD window glass is scratch and chemical resistant (H6 rating)

• Operating temperature -20°C-70°C

• Stainless steel probe with dust film

3. The use of ergonomic design to save time, can be used quickly and continuously without fatigue

• Overrun indicator, LED directly on the LCD and probe

• High-brightness 24-inch LCD, which can be viewed at a 70° angle

• Adjust the brightness of the LCD automatically or manually under sunlight to the best effect display

• Large tactile buttons and low weight medium

• Flip display 0°, 90°, 180°, 270°

4. Flexibility and scalability

• The main machine can be adapted to Fe (iron-based), NFe (non-iron-based),Fe/NFe (iron-based/non-iron-based) dual-purpose probes

• The main unit can be adapted to other types of probes

• Can be equipped with both integrated and split probes

• Quick and easy plug-and-play probe replacement

• Rapid adaptation to meet different needs

5. Friendly interface that is easy for users to understand, intuitive and operable, saving time and money

• Simple calibration for standard use

• The host and PC software are guided by intuitive menus, and the report can be reached in three steps

• Customizable keys for quick and direct single operation

• Pre-configured as standard

Diagram of the display

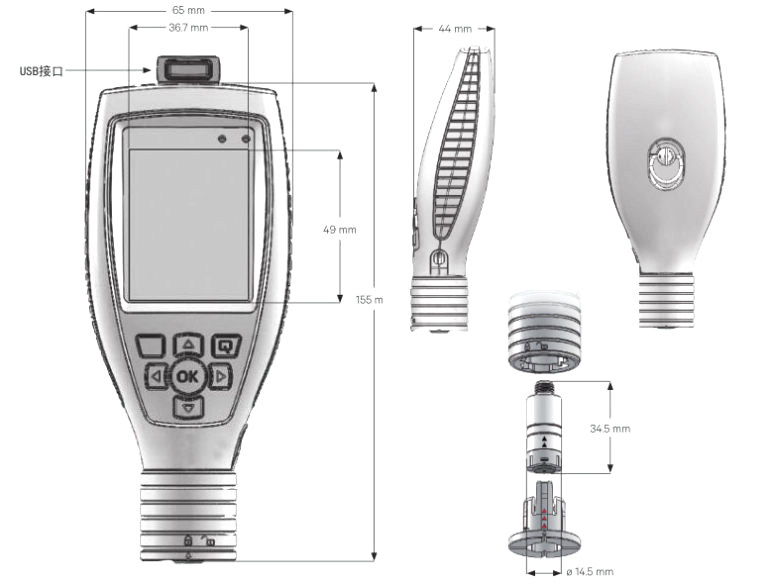

QNIX9500 Thickness Gauge Specification Drawing

Qnix QNix 9500PFe/NFe3mm Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction + eddy Current |

| Measurement range | 0~3000μm |

| margin of error | Fe: < 2.0mm : +/- ( 1 µm + 2% of reading); > 2.0mm: +/- 3% of reading; NFe: < 2.0mm : +/- ( 2 µm + 2% of reading); > 2.0mm: +/- 3% of reading; |

| Minimum measurement surface | Φ20mm |

| Minimum radius of curvature | Radius 20mm |

| thinnest substrate | 0.2mm(F);0.05mm(N) |

| probe | Integrated probe |

| Probe material | Ruby (Al203) |

| Calibrated mode | Zero calibrated, 1 point calibrated, 2 point calibrated, independent (independent adjustment) calibrated |

| Measurement mode | Manual selection of substrate, automatic selection of substrate, double substrate combined measurement, continuous measurement, button trigger measurement |

| Unit display | µm/mil conversion |

| Interface | USB port |

| Data storage | 1000000 measurement readings |

| Power Supply | 2xAA alkaline dry battery/rechargeable battery/USB |

| Standards | DIN EN ISO 2808, DIN 50981, DIN 50984, ISO 2178, BS 5411 (3 & 11), BS 3900-C5, ASTM B 499, ISO 2360, ASTM D 1400, ASTM D 1186, ASTM D 7091 |

| Display screen | 2.4-Inch IPS-LCD color liquid crystal, 600 lumens, 70 ° Viewing Angle |

| Operating temperature | -20 ℃ -70 ℃ |

| Battery life | When the battery is not in use, 50% Capacity > 1 year, 60,000 times |

| Protection level | IP64 |

| Machine Weight | 175 g |

| Machine size | 155*65*44 mm |

| Storage temperature | -20~70℃ |

| Probe support | Trogramid® |

| Body hard material | PA12 GF30 |

| Body soft material | TPE |

| system clock | CR1220 |

| Battery life | > 2 years |

| Pin code protection | Yes. |

| Calibrated value memory | 10 groups |

Qnix QNix 9500PFe/NFe3mm Coating Thickness Gauge Packing list

QNix9500Pro host, 2 zero adjustment boards, 2 standard pieces, factory test report, instruction manual, 2 1.5V AA alkaline batteries, plastic instrument case

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Tide Review: Coating Thickness Gauge QNix 9500PFe

- What is the difference between Magnetic Induction Film Thickness Gauge and eddy Current Film Thickness Gauge?

- Principle, Characteristics and Application of FISCHER Coating Thickness Gauge

- Basic Principle, Characteristics and Application of Rubber Coating Thickness Gauge

- Principle, Application and Type Selection of Electronic Coating Thickness Gauge

- QNIX 9500 Coating Thickness Gauge Real Photo Appreciation

- Film coating thickness measurement in industrial painting and cissing coating

- Coating Thickness Gauge for coated Film thickness measurement in vehicle evaluation

- Concept and basic knowledge of coating Thickness Gauge

- Application of QNIX Thickness Gauge in coated Film thickness measurement

- ActiveGB/T 44757-2024

- ActiveGB/T 13448-2019

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveHG/T 5367.1-2018

- ActiveGB/T 4956-2003

- AbolishGB/T 13448-2006

- AbolishGB/T 4956-1985

- ActiveGB/T 5209-1985

- ActiveQB/T 2183-1995

- ActiveGB/T 1733-1993

- ActiveGB/T 11374-2012

- ActiveGB/T 4957-2003

QNix 9500PFe/NFe3mm

QNix 9500PFe/NFe3mm