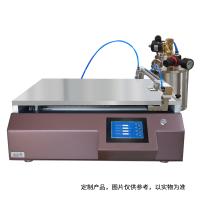

LEBO PF400-H Film Applicator Vacuum adsorption + heating

Vacuum adsorption + heating two-in-one, Drawdown Vacuum Plate size 540x345mm, high-precision PID temperature control, heating up to 200 ℃, uniformity of 1%, hard anodic oxidation aluminum panel, with waste glue collection tank, heavy base device to reduce vibration.

lebo

lebo-

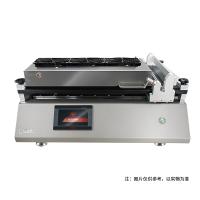

China TBJ-X1 Vacuum chuck Drawdown blade Lab Film Applicator Size 330 * 400mm

$ 3008.00 -

China TBJ-X3-DJ8 Automatic lame plating Vacuum chuck Film Applicator lame plating machine

$ 7649.00 -

HuiNuo TM3300Pro/22D drawdown Bar & blade heating vacuum adsorption Coater (floor type) ECA 120 * 50cm

Login -

HuiNuo TM1000Pro/UV Automatic Film Applicator (with UV curing) Laboratory Bar Coater servo motor

$ 2282.00 -

China TBJ-B2-DJ16 Floor drawdown Bar & blade Automatic Film Applicator Coating size 800 * 1000mm

$ 10807.00

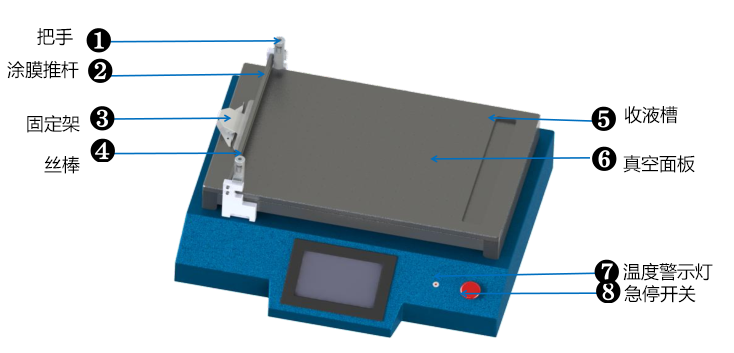

The PF400-H heated coater is used to prepare a uniform coating film, as the factor influencing the coating film is the shear raterate and weight added to the construction tool. The device uses a precisely controlled wire rod or applicator to selectMove back and forth at a fixed speed. Since the test strip is flatly adsorbed on the flat plate and the shear rate and application of the film are appliedThe force applied to the tool remains constant, which greatly improves the reproducibility of the coating film. At the same time, the aluminum alloy mirror is grindedGrinding flat panels can ensure that the panels are flat.

Features

Hard anodized aluminum panels for more solid and abrasion resistance

With waste glue collection tank, it is convenient to collect excess residual glue

Standard permeable vacuum platform with vacuum adsorption function on the surface

2-in-1 clamp, used separately with adjustable scraper or wire bar

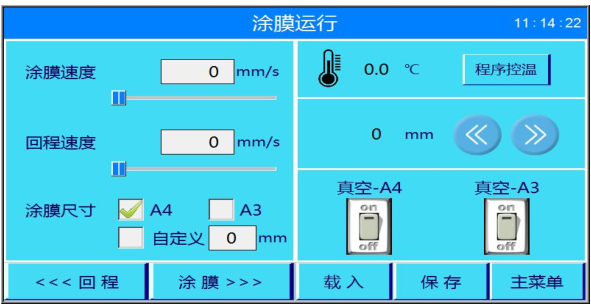

The coating film size can be A3, A4 or user-defined size, which can be flexibly selected

The gluing speed and return speed can be set arbitrarily to meet the diversity of the process

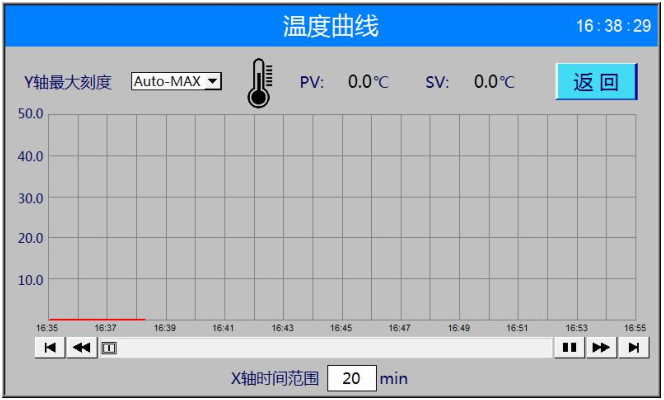

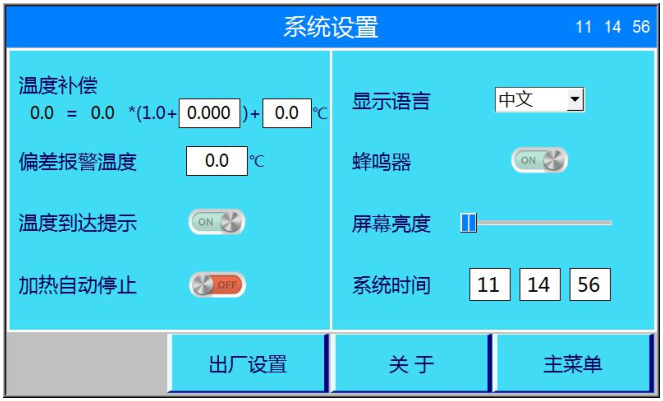

Using high-precision PID temperature control, the panel temperature is controllable and adjustable, and the temperature control accuracy is high

Linear temperature control heating can be carried out, the heating rate can be set, and the temperature control step is 5 steps

The maximum heating temperature is up to 200°C, with good thermal insulation design and high temperature uniformity

The panels and fixtures are designed as heavy-based devices to reduce vibration and prepare high-quality samples

Silent bearings and high-torque motors ensure a smooth and reliable coating process

Seven-inch full-color touchscreen operation with high temperature indication and emergency stop switch

It can be used with a range of Film Applicators and wire rods on the market

An external Vacuum Pump is required for vacuum adsorption. The PF400 is supplied with a 1-metre transparent vacuumTube. Connect one end of the vacuum tube to the vacuum tube connection on the back of the PF400 and the other end to your vacuumPump inlet. When using the PF400 Film Applicator, turn on the Vacuum Pump and check if the vacuum is normal.

Description of the main interface

Attachment selection

There are four specifications of adjustable Film Applicator to choose from, wet film range 0-3500μm, film width specification 55mm, 100mm, 150mm, 200mm four options. Other specifications need to be customized.

The length of the wire bar applicator is 400mm, and the wet film thickness is available in a variety of specifications (range from 6 to 200 μm).

A VPC200 Vacuum Pump is supplied as standard.

Optional

lebo PF400-H Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Coating speed | 0~300mm/s |

| Speed regulation Accuracy | 1mm/s |

| Spreader trip | 420mm |

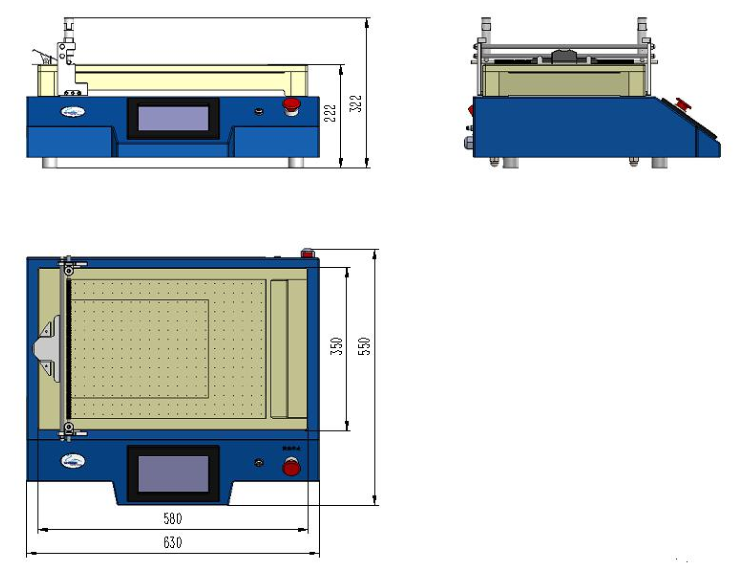

| Vacuum Area | 540*345mm |

| Vacuum Area | A4/A3 |

| Temperature range | RT+~200℃ |

| thermal uniformity | 1% |

| Host Power Supply | AC200V~ 240V, single phase, 50Hz, 2.5KW |

| Vacuum input requirements | 0.06-0.09Mpa |

| Vacuum Flow rate | 15L/Min or more |

| Vacuum interface | Outer diameter of equipment rear plate outlet 6mm |

| Dimension | 630*550*324mm |

| Weight | 37Kg |

lebo PF400-H Film Applicator Packing list

PF400-H device X1, touch screen pen X1, film applicator X1, power cord X1, product manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Automatic coating machine _ vacuum adsorption small coating machine how to install Vacuum Pump?

- Why did the small coater choose aluminum plate as the heating baseplate instead of stainless steel?

- Demonstration video of coating operation of small coater on ultra-thin diaphragm

- Preparation of Multilayer Medical Polymer Materials by Wire Bar Coater

- Preparation of PTFE Foam Coated Glass Fiber Composite Filter Material by Scraper Film Coater

- Preparation of foam coatings on fabric surfaces with a coating machine

- Preparation of electrode pads with a scraper coating machine

- Laboratory Coater for Preparation of Silver Nanowire-Graphene Composite Transparent Conductive Films

- Preparation of GO-modified TFC-FO membrane support layers with different particle sizes by film coating machine

- Preparation of Conductive Films on Nonwoven Fabrics by Small Coating Testing Machine

PF400-H

PF400-H

TBJ-GDHO-JKXB

TBJ-GDHO-JKXB