DAKOTA UMX-2 Underwater Thickness Gauge 2.54~ 100mm

DAKOTA underwater Thickness Gauge UMX-2 can be used for underwater measurement of materials and Coating thickness, rated depth of 300 meters, with dual components and unit Sensors, UMX-2 with PT-074-2906 underwater probe, thickness measurement range 2.54~ 100mm.

DAKOTA

DAKOTA-

Deguang Electronics D7004 Ultrasonic Thickness Gauge Probe, mainly used for measurement of thin walls and small arcs

$ 324.00 -

PRUT210 Ultrasonic Thickness Gauge Film thickness range 0.75~ 225mm

Login -

Deguang Electronics D5008 Ultrasonic Thickness Gauge Probe, this probe can be selected in various situations

$ 182.00 -

Defelsko posiTector200 B Standard 200B1-E Ultrasonic Thickness Gauge Wood/Plastic coating thickness measurement

$ 2793.00 -

Mattel MT160 Ultrasonic Thickness Gauge Thickness Range 0.75~ 300mm USB Interface

$ 356.00

Introduction

UMX-2 Thickness Gauge for Underwater Materials and Coatings, designed for offshore inspections, rated to a depth of 1000 feet (300 meters). The UMX-2 is very versatile and offers both two-element and single-element sensors. Equipped with a variety of measurement mode options, the UMX-2 will meet all your application needs. An on-board 5,000-point data logger stores all UMX-2 settings for each measurement as well as the actual A-scan waveform. Our Java-based DakView PC or MAC OSX software makes the toolkit very useful.

Features

Measurement modes: Dual element – pulse-echo, pulse-echo with coating, echo. Single element – triple return (TCG).

Automatic: Probe zeroing and probe identification.

Data storage format: Alpha numeric grid and sequential w/auto identifier.

Windows PC software included.

DAKOTA UMX-2 Underwater Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement range | 2.54~100mm |

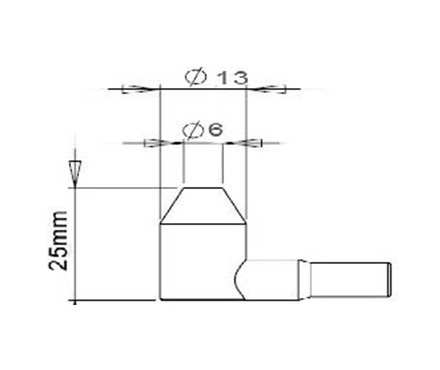

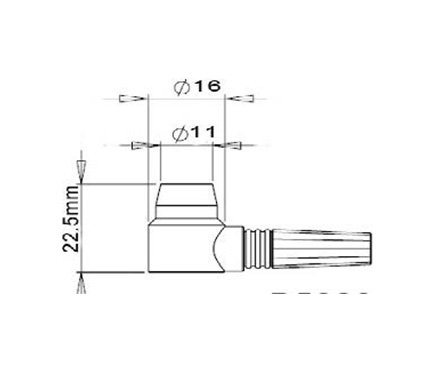

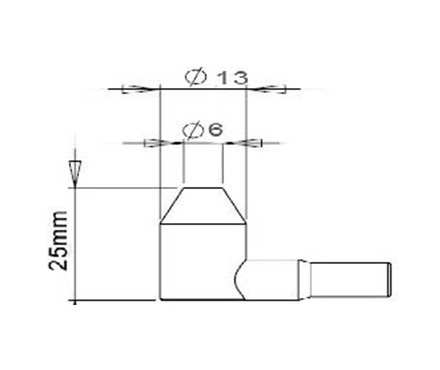

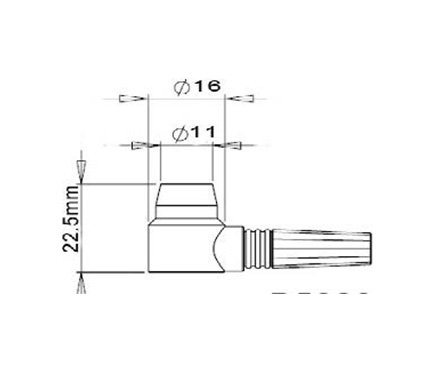

| Probe Frequency | 5MHz dual crystal probe. Custom automatic identification probe (defect and pit detection). |

| Probe style | Split probe |

| Probe diameter | Φ12.7mm |

| Probe line length | 4 foot cable |

| Display resolution | +/- 0.001 inches (0.01 mm) |

| unit system | Imperial and metric systems |

| Calibration method | 8 fixed and 1 programmable material speeds (in/µs): aluminum 2024-0.251; steel 4340-0.233; stainless steel 302-0.223; iron -0.232; cast iron -0.180; PVC-0.094; polystyrene -0.092; polyurethane -0.070; custom user |

| Measurement mode | Dual Element Probe Pulse Echo (PE): Off coating. Pulse Echo coating (PECT): On coating. Echo (EE): Through drawing. Single Element Probe Triple Echo (TCG): Through type. |

| Measurement speed | 0.0492 to 0.5510 inches/microsecond 1250 to 13995 meters/second |

| Storage Capacity | 5,000 readings, settings, and waveforms |

| Display | 1/2 " (12.7 mm) 4.5-bit LCD display. 3/8" (9.5 mm) 6 alpha LCD display. Both display backlit (on/off/automatic) |

| Interface | Bidirectional RS232 serial port with USB converter. Windows ® PC interface software |

| Environmental temperature | -20 ° to 140 ° F (-29 ° to 60 ℃) |

| Power Supply | Three 1.5V alkaline or 1.2V NiCad AA batteries |

| Host size | Length (9.0 inches/229 mm); Diameter (2.375 inches/60.33 mm) |

| Body material | High-strength clear plastic housing. Depth rating of 1000 feet (300 meters) |

| Weight | 1.5 lbs (0.680 kg) - with 3 AA batteries |

| memory | 32 trillion-bit non-volatile memory |

| programming | Storage Capacity is 1 file template. User specified size and Dimensions |

| Data Logging file format | Grid (alphanumeric); order (automatic identifier) |

| keyboard | Single button, magnetically coupled switch |

| Certificate type | Factory calibrated: traceable to national standards. IP68 rating. |

| pulse generator | Double square wave pulse generator |

| receiver | Dual Receiver Manual or AGC gain control with 110dB range (limited) |

| Timer | 25 MHz TCXO with single-shot 100 MHz 8-bit ultra-low power digitizer |

| Backlight off | Usually runs for 50 hours on alkaline batteries and 15 hours on nickel-cadmium batteries |

| Backlit | Usually 15 hours on alkaline batteries and 8 hours on Nicad |

| Automatic shutdown | After 5 minutes of inactivity |

| Pulse echo mode (PE) | (Pit and defect detection) Measurement range is 0.63 to 500mm |

| Pulse echo coating mode (PECT) | (Material, coating, pit and defect detection): Material: 0.63 to 500 mm. coating: 0.01 to 2.54 mm |

| Echo Mode (EE) | Via coatings and coatings) in sizes from 2.54 to 102 mm. The range will vary depending on the coating +/- |

| Triple Echo Mode (TCG) | Dimensions in steel by paints and coatings are 1 to 150 mm. Range will vary depending on Coating thickness, material type and probe |

DAKOTA UMX-2 Underwater Thickness Gauge Packing list

Host X1, PT-074-2906 underwater probe, coupling agent X1, No. 5 battery X2, factory certificate x1, Chinese and English instructions x1, instrument case x1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Use of Ultrasonic Thickness Gauge and its indication

- The Working Principle of Ultrasonic Thickness Gauge and Its Use

- Application of Ultrasonic Thickness Gauge in Oil Drilling Tools Production

- Application of Ultrasonic Thickness Gauge in Spinning Tube Abrasion Monitoring

- Influencing factors of ultrasonic thickness indication distortion

- Application of Ultrasonic Thickness Measurement Technology- "Selection of Thickness Gauges"

- How to measure the thickness of galvanized layer _ galvanized layer thickness inspection method

- Advantages of Dakota UMX-2 Underwater Coating Thickness Gauge

- GB/T13452.2-2008 Determination of film thickness of Paints and varnishes [text version]

- Ultrasonic Instrument FAQ

UMX-2

UMX-2