ASR-5612 Wear Tester

The outer diameter of the test piece is 100mm, the inner diameter is 6.35mm, the film thickness is 6mm, the counter LCD is displayed, the machine is automatically stopped, and the speed of the test plate is 60/72/min or specified.

AISRY

AISRY-

CHINA NBC-5613 Linear Wear testing machine abrasion Tester

$ 1098.00 -

MODERNER JM-V abrasion instrument (wood configuration) load 250g

Login -

HUITAO CSI-345 reciprocating abrasion Tester, scratch resistance and wear resistance Tester

$ 5037.00 -

HUITAO CSI-252 DIN Wear resistance Tester Abrasion Tester

$ 1287.00 -

HUITAO HT-D270 Carpet Caster Wear resistance Tester meets a variety of standard foot wheel, automatic lift

$ 7010.00

Introduction

This machine is suitable for wear resistance test of leather, cloth, paint, paper, floor tile, plywood, glass, natural rubber, etc. The method is to cut the test piece with a standard cutter, use a specified type of grinding wheel, and load a certain weight to wear it. After reaching the specified number of revolutions, take out the test piece, observe the condition of the test piece after grinding or the weight difference between the weight of the test piece before the test and the weight after the test. The formula for calculating the wear index: weight lost by wear/test revolutions×1000

The main function

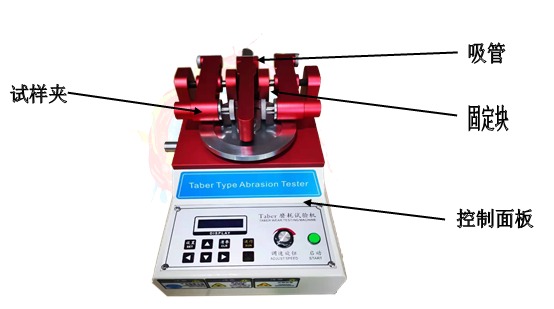

The upper part of the instrument is a sample fixture and a pair of abrasive wheels. The abrasive wheel is attached with a counterweight. The sample holder is rotated by the motor to drive the abrasive wheel, so that the abrasive wheel and the sample are rubbed. After a certain number of frictions, Stop the operation of the instrument, remove the sample, observe the degree of wear to evaluate its wear resistance, and provide reference data for material selection.

This instrument complies with the following standards: DIN-53754, 53799, 53109, 52347 TAPPI-T 476 GB/T1768-2006 ASTM-D 4157, 4060

Steps

1. Sample preparation

3.1.1 The sample should be placed in the state of temperature 23±1℃ and Relative Humidity 65±2% for more than 48 hours before the test.

3.1.2 Sampling standard cutter and sample cutting machine Cut the standard specification sample with an outer diameter of 100mm, an inner diameter of 6.35mm, and a thickness of 3mm, and stick the sample on a standard sticker of the same size. For spraying samples, make test pieces according to the requirements of ASTM D823, and the area of the substrate is 100mm in diameter.

2. Preparation before the test

2.1 Lift up the pressure rod and the vacuum tube.

2.2 Loosen and take off the fixing nut of the grinding wheel, select the model of the grinding wheel according to the test standard and install it in the center of the left and right grinding wheel axles to fix the nut.

2.3 According to the standard of the test, select the weights to be installed on the left and right counterweight shafts, and the weights of the counterweights must be the same.

2.4 Whether the machine is connected to a power supply that meets the required specifications.

3. Testing process

1 dressing grinding wheel (applicable when using rubber grinding wheel)

1) Take off the compression nut and gasket, loosen the fixing screw with a wrench, and pick up the fixing ring.

2) Place the sandpaper disc (H-17), put the gasket on, and fix the sandpaper disc with the compression nut.

3) Put the fixing ring on, flatten the sandpaper, and fix the sandpaper with the fixing nut with a wrench.

4) Set the number of rotations.

5) Connect the vacuum cleaner: Connect the vacuum cleaner's suction pipe to the connector on the left side of the machine, pull out the power cord of the connector vacuum cleaner, turn on the power, and start the vacuum cleaner.

6) Turn on the power switch of the main engine, set the required number of revolutions with the speed control knob, and select the speed (60 revolutions per minute) and (72 revolutions per minute). Press the start button, the machine will stop automatically after the set number of times is reached.

7) According to step 1), lift the key lever and vacuum tube, and remove the sandpaper disc.

Note: The grinding wheel needs to be refurbished with sandpaper every 500 revolutions.

2 tests

1) Use an electronic balance to weigh the weight of the sample before the test.

2) The operation steps are the same as 1.1-1.6

3) Take down the sample, and weigh the sample again with an electronic balance after the test.

3 result judgment

1) After the set number of times is reached, observe whether the test is damaged or how many times it is damaged.

2) Wear index=[(W1-W2)/N]×1000

illustrate:

W1: test weight before test

W2: test weight after test

N: number of test revolutions

AISRY ASR-5612 Wear testing machineSpecifications

| LIST | VALUE |

|---|---|

| test piece | Outer diameter 100mm, Inner diameter 6.35mm, Film thickness 3mm |

| Load | 250g,500g,750g,1000g |

| Counter | LCD liquid crystal display |

| Test disk speed | 60/72/min or specified |

| Machine size | 260*375*300mm |

| Machine Weight | About 18kg (without vacuum cleaner) |

| plastic | H18 (Miscellaneous model needs to be purchased) |

| Power | AC220V 50HZ 5A |

AISRY ASR-5612 Wear testing machine Packing list

Host X1 unit, load weight 250g × 1 pair, load weight 750g × 1 pair, sample clamp ring × 1 set, power cord × 1 piece, abrasion wheel × 1 pair, new sandpaper × 1 piece, hexagon wrench × 1 set, toolbox × 1, manual × 1, vacuum cleaner × 1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Hot melt adhesive testing instrument scheme for sanitary napkins [in line with HG/T 3948]

- Lithium-ion battery separator performance testing scheme [with instrument list]

- Paper tear Tester operating instructions

- ASR-XJJ-11B Digital Display Cantilever Impact Testing Machine Operation Manual

- ASR-MFY-02 Vacuum Sealing Performance Tester Instruction Manual

- ASR-8516 Single Wing Drop Testing Machine Operation Manual

- Operation Manual of Asiri Taber Wear Tester

- ASR-5608 Electric Pencil Hardness Tester Operation Manual

- ASR-5622 Electric Decolorization Testing Machine Operation Manual

- Asiri Simulates Automobile Transportation Shaker Operation Manual

- ActiveGB/T 44757-2024

- ActiveGB/T 13448-2019

- ActiveGB/T 22374-2018

- ActiveGB/T 12967.1-2020

- ActiveGB/T 8013.1-2018

- ActiveHG/T 5367.1-2018

- ActiveHG/T 5183-2017

- AbolishGB/T 13448-2006

- ActiveGB/T 1768-2006

- AbolishGB/T 1768-1979

ASR-5612

ASR-5612