HTechMT CO600FBB1 platings Thickness Gauge, iron-based, basic type 1600 μm

Type B iron-based integral belt type, 1.6mm, screen statistics function

HTechMT

HTechMT-

Defelsko NAS split thin coating probe

$ 1049.00 -

QNix 9500 Coating Thickness Gauge, basic

$ 1204.00 -

List MEGA-CHEK Master Storage Fast Scan Platings Thickness Gauge

$ 2156.00 -

Defelsko F90S split 90 ° right angle probe measurement low headroom area

$ 1049.00 -

Defelsko PosiTector 6000 FRS1 import Thickness Gauge paints/film/film thickness measurement

$ 1058.00

The coating Thickness Gauge can quickly and accurately measure the thickness of non-magnetic coatings or coatings (such as aluminum , chromium, copper, enamel, rubber, paint, etc.) on magnetic metal substrates (such as steel, iron) and non-magnetic metal substrates (such as The thickness of non-conductive coatings (such as enamel , rubber, paint, plastics, etc.) on copper, aluminum, zinc, tin, etc.).

Implementation standards: ISO 2178/2360/2808, ISO 19840, ASTM B244/B499/D1186/D1400

CO600 series classification

CO600 FA E 1

1 Range type: 1/2/3/4/5 corresponds to 1.6, 5.0, 14.0, 25.0 and 0.5mm (whole and whole with line type)

E: Function type: Economic type (E), basic type (B), statistical type (S), advanced type (T)

A: Host and probe connection types: integral type (A), integral with line type (B) and split type (C)

F: Substrate type: Iron-based (F), non-ferrous-based (N)

split type

| B (basic type) | S (standard type) | T (advanced type) | |

| iron base | CO600FCB | CO600FCS | CO600FCT |

| Non-ferrous | CO600NCB | CO600NCS | CO600NCT |

Integral

| Measuring range | E (Economy type) | B (basic type) | ||

| Integral | Overall wired | Integral | Overall wired | |

| Iron base 0.5mm | CO600FAE5 | CO600FBE5 | CO600FAB5 | CO600FBB5 |

| Iron base 1.6mm | CO600FAE1 | CO600FBE1 | CO600FAB1 | CO600FBB1 |

| Iron base 5.0mm | CO600FAE2 | CO600FBE2 | CO600FAB2 | CO600FBB2 |

| Iron base 13.0mm | CO600FBB3 | |||

| Non-ferrous base 0.5mm | CO600NAE5 | CO600NBE5 | CO600NAB5 | CO600NBB5 |

| Non-ferrous base 1.6mm | CO600NAE1 | CO600NBE1 | CO600NAB1 | CO600NBB1 |

| Non-ferrous base 5.0mm | CO600NAE2 | CO600NBE2 | CO600NAB2 | CO600NBB2 |

| Non-ferrous base 13.0mm | CO600NAE3 | CO600NBE3 | CO600NAB3 | CO600NBB3 |

| Measuring range | S (standard type) | T (advanced type) | ||

| Integral | Overall wired | Integral | Overall wired | |

| Iron base 0.5mm | CO600FAS5 | CO600FBS5 | CO600FAT5 | CO600FBT5 |

| Iron base 1.6mm | CO600FAS1 | CO600FBS1 | CO600FAT1 | CO600FBT1 |

| Iron base 5.0mm | CO600FAS2 | CO600FBS2 | CO600FAT2 | CO600FBT2 |

| Iron base 13.0mm | CO600FBS3 | CO600FBT3 | ||

| Non-ferrous base 0.5mm | CO600NAS5 | CO600NBS5 | CO600NAT5 | CO600NBT5 |

| Non-ferrous base 1.6mm | CO600NAS1 | CO600NBS1 | CO600NAT1 | CO600NBT1 |

| Non-ferrous base 5.0mm | CO600NAS2 | CO600NBS2 | CO600NAT2 | CO600NBT2 |

| Non-ferrous base 13.0mm | CO600NBT3 | |||

Series differences

| CO600 | E | B | S | T | |

| Coating Thickness Gauge | Economical | Basic type | Standard type | Advanced type | |

| Overview | Dimensions | 70*150*32mm | |||

| Weight (including battery) | 200g | ||||

| Display | 2.2 TFT | ||||

| Battery | 2 AA batteries (rechargeable batteries available) | ||||

| Battery life1 | 20 hours | ||||

| operating temperature | -10~50 o C | ||||

| Accuracy 2 | ±(1-3)% | ||||

| Test speed | 60 times/minute | ||||

| Function settings | Low battery alarm | â | â | â | â |

| Smooth two-point calibration | â | â | â | â | |

| Rough two-point calibration 1 | â | â | â | ||

| Rough two-point calibration 2 | â | â | â | ||

| Zero point calibration | â | â | â | ||

| Factory calibration | â | â | â | â | |

| Language 3 | â | â | â | â | |

| ambient light sensor | â | â | â | â | |

| Automatically rotate screen | â | â | â | ||

| Test tone adjustment | â | â | â | ||

| Display brightness adjustment | â | â | â | ||

| Upper and lower limit functions | â | â | â | ||

| Screen settings | Screen statistics function | â | â | â | |

| Number of measurements | â | â | â | ||

| maximum value | â | â | â | ||

| minimum value | â | â | â | ||

| average value | â | â | â | ||

| standard deviation | â | â | â | ||

| Array statistics | New group | â | â | ||

| open group | â | â | |||

| View group | â | â | |||

| clear group | â | â | |||

| Delete group | â | â | |||

| Exit group | â | â | |||

| Number of groups | 10 sets | 100 groups | |||

| Total storage | 100,000 | 1 million | |||

| other | USB connection to PC | â | â | â | â |

| Data download to PC | â | â | |||

| Firmware upgrade | â | â | â | â | |

| Wifi | â | â | |||

1 There are differences between different batteries or settings;

2 The accuracy depends on the accuracy of the standard film and the user's proficiency;

3 Language types will be updated without further notice, please contact customer service.

Probe selection

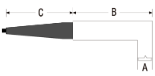

| shape | Probe model | A | B | C | Measuring range | Accuracy 1 | Minimum headroom | Minimum test radius | Minimum substrate thickness |

| CO600F1S | 9 | 40 | 50 | 1.6mm | ±1-3% or 2.5 μm | 80mm | 5mm | 0.8mm |

| CO600F2S | 9 | 40 | 50 | 5.0mm | ±1-3% or 20 μm | 80mm | 5mm | 0.8mm | |

| CO600F5S | 9 | 40 | 50 | 0.5mm | ±1-3% or 2.0 μm | 80mm | 5mm | 0.8mm | |

| CO600F1H | 9 | 40 | 50 | 1.6mm | ±1-3% or 2.5 μm | 80mm | 5mm | 0.8mm | |

| CO600F2H | 9 | 40 | 50 | 5.0mm | ±1-3% or 20 μm | 80mm | 5mm | 0.8mm | |

| CO600N1S | 9 | 40 | 50 | 1.6mm | ±1-3% or 2.5 μm | 80mm | 5mm | 0.3mm | |

| CO600N2S | 9 | 40 | 50 | 5.0mm | ±1-3% or 20 μm | 80mm | 5mm | 0.3mm | |

| CO600N5S | 9 | 40 | 50 | 0.5mm | ±1-3% or 2.0 μm | 80mm | 5mm | 0.3mm | |

| CO600F1R | 9 | 40 | 50 | 1.6mm | ±1-3% or 2.5 μm | 30mm | 5mm | 0.8mm |

| CO600F2R | 9 | 40 | 50 | 5.0mm | ±1-3% or 20 μm | 30mm | 5mm | 0.8mm | |

| CO600N1R | 9 | 40 | 50 | 1.5mm | ±1-3% or 2.5 μm | 30mm | 5mm | 0.3mm | |

| CO600N2R | 9 | 40 | 50 | 5.0mm | ±1-3% or 20 μm | 30mm | 5mm | 0.3mm | |

| CO600F3S | 16.5 | 40 | 50 | 13.0mm | ±1-3% or 50 μm | 80mm | 10mm | 1.0mm |

| CO600F4S | twenty four | 60 | 50 | 26.0mm | ±1-3% or 100 μm | 120mm | 30mm | 1.0mm |

*High temperature probe temperature is 250℃

HTechMT CO600FBB1 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction |

| Measurement range | 0~1600mm |

| margin of error | ±1~3%/2.5μm |

| Minimum headroom | 80mm |

| Minimum measurement surface | R5mm |

| thinnest substrate | 0.8mm |

| probe | Standard probe |

| Probe material | ruby |

| Calibrated Certificate | none |

| Calibrated mode | Smooth two-point calibrated, rough two-point calibrated 1, rough two-point calibrated 2, zero-point calibrated, factory calibrated |

| Unit display | μm |

| statistical function | Measurement times, MAX Maximum, MIN Minimum, Average, Standard deviation |

| Interface | USB |

| Power Supply | 2 AA batteries (rechargeable batteries can be used) |

| Standards | ISO 2178/2360/2808、ISO 19840、ASTM B244/B499/D1186/D1400 |

| Language | Chinese, English, German |

| Display screen | 2.2TFT |

| Operating temperature | -10~50℃ |

| Battery life | 20h |

| Protection level | IP64 |

| Print function | No |

| Machine Weight | 200g |

| Machine size | 70*150*32mm |

| Test speed | 60 times/minute |

| Battery life | 20h |

HTechMT CO600FBB1 Coating Thickness Gauge Packing list

host X1, AA battery X2, test piece set X1, zero adjustment plate X1, certificate X1, manual X1, silicone protective cover X1, instrument bag (cloth bag) X1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveGB/T 42541-2023

- ActiveGB/T 13912-2020

- ActiveGB/T 7991.5-2014

- ActiveGB/T 13448-2019

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveHG/T 3369-2003

- ActiveSY/T 0315-2013

- ActiveGB/T 4956-2003

- AbolishGB/T 13448-2006

- ISO 6158-1984

- ActiveISO 1461-2022

- AbolishGB/T 4956-1985

- ActiveQB/T 2183-1995

- ActiveJB/T 7217-2008

- ActiveJB/T 7663.2-2007

CO600FBB1

CO600FBB1