CHINA ASR-4324 Glow Wire Tester

Interior volume 60x95x90cm, temperature measuring device 0.5mm armored filament thermocouple, can withstand high temperature of 1050 ℃, temperature range 500~1000 ℃, digital display adjustable.

AISRY

AISRY-

YOUKE YK3261 UL1581 Wire and cable combustion Tester

$ 6071.00 -

YOUKE YK3260 single line vertical combustion testing machine

$ 1193.00 -

YOUKE YK3056 Needle Flame Tester (Touch Screen)

$ 1808.00 -

CHINA NBC-4321 Wire and cable horizontal vertical combustion testing machine, wire flame retardant Test Chamber

$ 676.00 -

YOUKE YK3054 Glow Wire Tester (Touch Screen)

$ 1808.00

Parts of electrotechnical and electronic equipment may be exposed to thermal stress due to electrical effects, and their deterioration may reduce the safety performance of the equipment . These parts should not be unduly affected by heat and fire generated inside the equipment. Parts of insulating material or other solid combustible material that are prone to spread flames inside equipment may ignite due to Glow-Wires or hot components. Ignite under certain conditions, such as fault current flowing through the conductors, component overloading, and hot components with poor contact . This Tester simulates heat sources or ignition sources such as burning components or overload resistors under fault or overload conditions. This Tester simulates heat sources or ignition sources such as burning components or overload resistors The thermal stress caused in a short period of time is used to assess the fire hazard of the product. It is suitable for fire hazard test . The Tester is based on IEC60695-2-10/11/12/13, IEC60669-1, 1EC60884-1, UL1598, GB5169.10, GB5169.11 and GB4706.1. It is designed and manufactured according to the relevant items stipulated in "Safety of Household and Similar Electrical Appliances Part 1: General Requirements".

Principle

The test box is divided into left and right parts, the left part is the scorching combustion chamber, and the right part is the electrical control room. After the sample is installed in the sample fixture, it is driven by a motor, which can run forward and backward, and is automatically controlled during the test. The glow wire is fixed, and the sample trolley is moved the glow wire head, and the trolley is pulled with a weight to keep the applied pressure IN, and there is a limit device to limit the pressing depth to 7mm. The glow wire application time Ta (T1) is preset and controlled by the digital display time relay. The flame ignition time Ti (T2) is measured by a digital display time relay and controlled by a button switch. The flame extinguishing time Te (T3) is measured by a digital display time relay and controlled by a button switch. The electrical control system uses the control of the glowing current to change the glowing temperature. The temperature control instrument is used to accurately control the temperature of the Glow-Wire. The K-type armored thermocouple has high precision and high reliability.

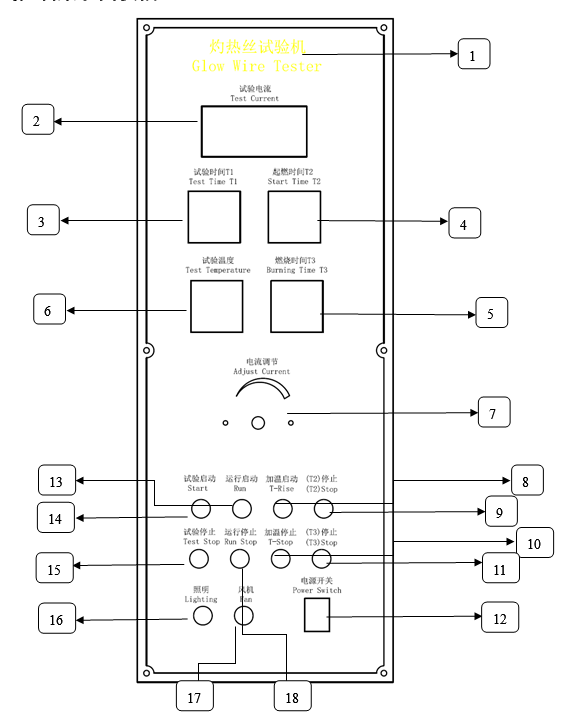

electrical control panel

1) Name of testing machine

2) Ammeter - Indicates the size of the glow wire current

3) Timer T1: Test (burning) time (Ta) - Timer for burning the sample

4) Timer T2: Ignition ignition time (Ti) - sample flame ignition time

5) Extinguishing time T3 (Te) - press this timer when the sample flame is extinguished

6) Temperature display instrument - display set temperature and burning temperature

7) Heating current regulator - adjust the heating current

8) Heating start switch (T-rise) - press this switch button to adjust the current

9) Ignition timing stop switch (T2 stop) - press this switch button to stop timing for T2 and start timing for T3

10) Heating stop switch (T-stop) - press this switch button to stop heating

11) Combustion timing stop switch (T3 stop) - press this switch button to stop timing by T3

12) Power switch - press this switch button to turn on the glow wire testing machine

13) Run start - press this switch button and the sample trolley starts to move

14) Test start - press this switch button and the burning test machine enters the state to be tested

15) Test stop - press this switch button and the burning test machine enters the test end state

16) Lighting switch - control lighting

17) Fan switch - control the fan to extract exhaust air

18) Running stop - press this switch button and the sample trolley stops moving

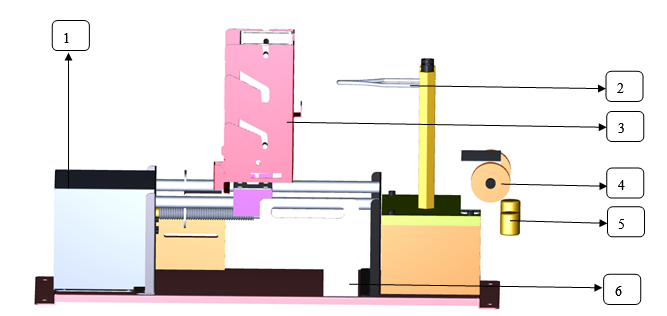

Glow Wire Structural Parts

1) Power drive device

2) Glow wire probe

3) Sample trolley

4) Weight pulley

5) 1N weight

6) Limit switch

Precautions

When the glow wire heats up, please close the door and observe to avoid burns.

Use a three-pole socket with a ground wire for the power supply to ensure reliable grounding.

Pay attention to protect the thermocouple and glow wire of the temperature controller. Be careful not to damage it when cleaning the lumps on top of the glow wire

Thermocouples, thermocouples are consumables and are not covered by the warranty.

Be sure to pay attention to polarity when replacing thermocouples.

Do not turn on the lighting switch and ventilation switch during the scorching process

If you find that the burning flame of the hot material is too large, please immediately turn off the power switch, unplug the power cord, and immediately use a fire extinguisher to extinguish the fire

AISRY ASR-4324 Glow Wire TesterSpecifications

| LIST | VALUE |

|---|---|

| test space | 0.5M3, D x W x H 60x95x90cm |

| Dimensions | W x D x H 113x57x120cm |

| Glowing wire | 4.0mm diameter ring made of nickel/chromium wire |

| thermocouple | 0.5mm armored filament thermocouple, capable of high temperature of 1050 ℃ |

| Heating current | When the temperature is 960 ℃, the current is between 120 and 150A |

| Force applied to the test | 0.8~ 1.2N, and limit the pressing depth to at least 7mm |

| Timer | Ignition duration (Ti) and flame extinguishment time (Te) can be recorded |

| Glowing wire temperature | 500~1000 ℃, digital display adjustable |

| temperature tolerance error | ± 10 ℃ (500~750 ℃), ± 15 ℃ (750~1000 ℃), the temperature is ± 0.5 grade |

AISRY ASR-4324 Glow Wire Tester Packing list

Host X1, manual X1, warranty card X1, certificate X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Hot melt adhesive testing instrument scheme for sanitary napkins [in line with HG/T 3948]

- Lithium-ion battery separator performance testing scheme [with instrument list]

- Paper tear Tester operating instructions

- ASR-XJJ-11B Digital Display Cantilever Impact Testing Machine Operation Manual

- ASR-MFY-02 Vacuum Sealing Performance Tester Instruction Manual

- ASR-8516 Single Wing Drop Testing Machine Operation Manual

- Operation Manual of Asiri Taber Wear Tester

- ASR-5608 Electric Pencil Hardness Tester Operation Manual

- ASR-5622 Electric Decolorization Testing Machine Operation Manual

- Asiri Simulates Automobile Transportation Shaker Operation Manual

ASR-4324

ASR-4324