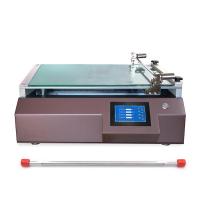

China TBJ-A2 Heating Wire Rod Lab Film Applicator with Heating Scraping Machine

Film bar Spreader, with heating function, can be heated and dried, touch screen control, simple and fast operation; suitable for lithium battery film, coating speed is 1~ 140mm/s, baseplate is aluminum alloy material.

zy

zy-

China TBJ-A1-DJ8 high-precision bar Lab Film Applicator Servo Motor Film Applicator

$ 1966.00 -

HuiNuo TM3200Pro/06 Automatic Film Applicator bar drawdown blade Coater ECA 60cm * 50cm servo motor

$ 6702.00 -

China TBJ-B3 Heating Drawdown blade Lab Film Applicator Automatic Film Applicator

$ 2282.00 -

HuiNuo TM1300Pro/01D Floor type bar heating Vacuum chuck Coater 100 * 90cm

Login -

HuiNuo TM3000Pro/18D Automatic Film Applicator drawdown Bar & blade Coater (floor model) ECA 100 * 30cm servo motor

$ 6860.00

The touch laboratory TBJ-A wire rod coating testing machine is a newly upgraded product that is carefully designed to coat precise wet films on different substrates. It can repeatedly and continuously prepare smooth, flat and flawless coatings. After testing samples, the equipment has been favored by many familiar companies, research and development institutions, and colleges and universities after it was put into the market.

Optional

zy TBJ-A2 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

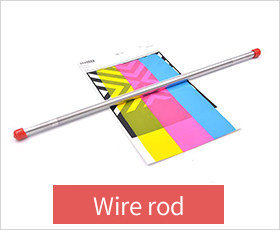

| Coating method | bar |

| Mayer Rod Thickness Range | 1-571.5 μm (Spreader thickness according to bar model) |

| Mayer Rod Accuracy | ±0.001mm |

| Coating speed | 5-200Mm/s (< 5mm/s can be customized) |

| Coating size | 400Mmx300mm (Miscellaneous size can be customized) |

| Substrate clamping method | Mechanical fixture |

| Control mode | Touch screen |

| Heating Temperature range | RT+~180℃ |

| Temperature Accuracy | ±3℃ |

| Bottom plate material | aluminum alloy |

| Heating mode | Aluminum baseplate heating |

| Dimension | 622*400*280mm |

| Host Power Supply | Single phase 220V 50Hz 100VA |

| Net Weight | 60kg |

| Optional Accessories | Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle |

| customizable function | Automatic lame plating device, UV curing device, automatic inking system, air knife drying, remote control, upper infrared heating, double extrusion Spreader |

zy TBJ-A2 Automatic Film Applicator Packing list

Film Applicator X1, China bar X1, Product manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Laboratory Film Applicator Drive Selection: Servo Motor and Stepper Motor

- Application and Development Trend of Plasticizers in Coating Industry

- Technical principle and operation precautions of water-based composite rubber coater

- Application Experiment of Automatic Film Applicator for Spreader Chitosan Film

- Application and Advantage Analysis of Polyetherimide Coated on Glass by Laboratory Coater

- Experimental Film Applicators: Guidelines for Selection, Operation and Application

- The Film Applicator You Think Is Not What You Think

- Application and Optimization of PDMS Solution Coated on Glass by Small Film Applicator

- Analysis of hot melt film coater technology: common failure causes and effective solutions

- Resin hot-melt adhesive coater technology depth analysis

- ActiveGB/T 41515-2022

- ActiveGB/T 1727-2021

- ActiveHG/T 3355-2003

- ActiveHG/T 4914-2016

- ActiveASTM D823-2018

TBJ-A2

TBJ-A2