MODERNER WQ-ⅱ Bending Tester

MODERNER cylindrical Bending Tester WQ-II can be used for test plates with a thickness of not more than 1mm. It is a Paints varnish coating cracking resistance test equipment. WQ-II is equipped with 12 shafts of different diameters

Moderner

Moderner-

TQC SP1820 cylindrical mandrel bending Tester, test plate size 180x100mm

$ 3991.00 -

JINGKELIAN QTY-32-III Film Bending Tester cylindrical mandrel bending test machine, film flexibility

$ 337.00 -

PUSHEN ZQ-V Conical Mandrel Bending Tester

$ 656.00 -

TQC SP1830 Conical Mandrel Tester Pro

$ 3016.00 -

JINGKELIAN QTY-32 cylindrical mandrel bending Tester to determine the ability of the paint film to deform with the substrate without damage

$ 274.00

Overview

The WQ-II cylindrical flexure Tester is used for testing the resistance to cracking and peeling from the substrate when the coating of pigments, varnishes and related products is bent around the cylindrical shaft, in accordance with the national standard GB/T 6742-2007 (equivalent to the ISO 1519:2002 standard of the International Organization for Standardization). This instrument can be used for test boards with a thickness of no more than 1mm, as long as the shaft is not deformed, and can also be used for thick soft metals such as aluminum test plates and plastic test plates. For boards with a thickness greater than 0.5 mm, it is recommended to avoid using shafts with a diameter of less than 10 mm for testing.

The bending part is a nylon guide plate, which can be adjusted by rotating the handle with the position of the shaft rod (sleeve). The bent parts can be flipped 180 degrees around the copper sleeve, and the inner hole of the copper sleeve is used to install various specifications of shaft rods. The 20mm, 25mm and 32mm specifications are bushings, which can be sleeved on the 16mm shaft rod when used. To prevent the coating from being scratched during bending, a piece of tissue paper can be inserted between the test plate and the bent part.

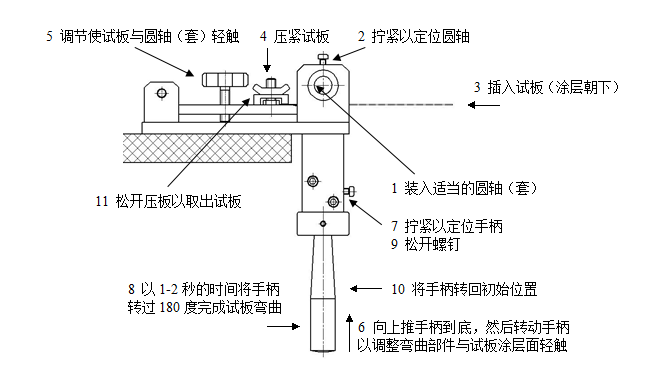

Structure and operation (see attached drawing)

The bending part is a nylon contact plate, which can be adjusted by turning the handle in the position of the round shaft (sleeve). The bent parts can be rotated around the copper sleeve, and the middle of the copper sleeve is used to install various specifications of round shafts. The 20mm, 25mm and 32mm specifications are round sleeves, which can be set on the 16mm round shaft when used. To prevent the coating from being scratched during bending, a piece of tissue paper can be inserted between the test plate and the bent part.

Moderner WQ-Ⅱ Bending TesterSpecifications

| LIST | VALUE |

|---|---|

| Shaft rod size | 2/3/4/5/6/7/8/10/12/16/20/25/32mm |

| plate thickness | ≤0.5mm或≤1mm |

| panel width | ≤60mm |

| Test plate length | ≤150mm |

| meet the standard | GB/T 6742-2007 |

Moderner WQ-Ⅱ Bending Tester Packing list

Host, 1 piece each of 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 16mm round shaft, 1 piece each of 20mm, 25mm, 32mm round sleeve

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveJB/T 3078-2015

- ActiveISO FDIS 1519-2010

- ActiveNF

- Active 2099-2013

- ActiveDIN EN ISO 1519-2003

- ActiveNF EN ISO 1519-2002

- ActiveGB/T 9989.4-2015

- ActiveISO 1519-2011

- ActiveGB/T 6742-2007

WQ-Ⅱ

WQ-Ⅱ