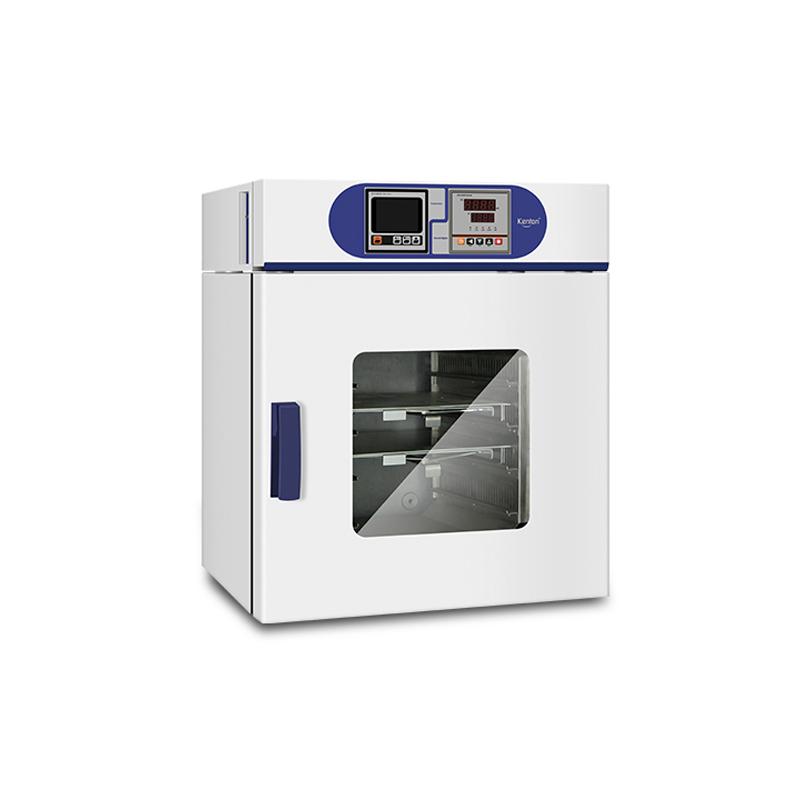

Kenton KZ-50G LCD screen Vacuum Oven 50L

KentonKZ-50G LCD screen Vacuum Oven Vacuum range (absolute pressure) 0~999.9mb, Temperature resolution +/- 0.1 ℃, Temperature range 50~250 ℃, liner volume 50 liters, KZ-50G LCD screen Vacuum Oven can fully display the status display required by customers: temperature, wind speed, running time, running stop.

Kenton

Kenton-

CHINA DZG-6050 Vacuum Oven 1300W/50L

$ 616.00 -

YIHENG DZF-6216A Vertical Vacuum Oven (microcomputer with timing)

$ 5111.00 -

YIHENG DHG-9140A Forced Air Drying Oven Power 2050W Volume 136L

$ 684.00 -

YIHENG BPZ-6063LCB Vacuum Oven imported Vacuumpump

$ 3610.00 -

YIHENG DZF-6032 Experimental Vacuum Oven (chemical special) temperature control up to 200 ℃

$ 867.00

Introduction

It is specially designed for drying heat-sensitive and easily oxidized substances, especially suitable for powdery or granular samples, and effectively shortens the drying time, so it is used in biology, industry, agricultural research and other fields;

The ALLHEAT™ inner cavity pre-heating technology and S.H-Transfer™ shelf heat transfer and other professional technologies are used to make the temperature distribution of the inner cavity uniform, and the constant temperature ensures that the experiment can be carried out smoothly;

Chinese/English IQ, OQ, PQ can be provided. And can provide a variety of verification services;

This series of products has passed the EU CE safety certification, in line with the Australian AS/NZS3350 standard, and enjoys a 2-year quality warranty.

Inner cavity preheating technology

ALLHEATTM's professional inner cavity preheating technology is to evenly distribute the heating elements around the inner tank, preheat the inner wall of the inner cavity, and then through heat transfer and forced fan convection, so that the temperature of each point in the cavity can be accurately reached and maintained at the set value, so as to ensure the uniform distribution of temperature in the cavity;

Equipped with ALLHEATTM series products, due to the uniform distribution of heat, it has the characteristics of low energy consumption and heat energy is not easy to dissipate, so that customers can reduce the cost of use.

ALLSENSTM microcomputer PID control technology

Integrated LCD dot matrix large screen LCD screen, can choose Chinese or English display, all parameters display at a glance.

Humanized design, comprehensive display of customer required status display: temperature, wind speed, running time, operation stop.

Adaptive PID degree control, precise temperature control, prevent temperature overshoot, and keep the temperature in the cavity uniform and constant.

User password control, built-in multi-function memory menu, and can be connected to multiple devices (up to 16) at the same time through the standard RS485 interface for real-time monitoring.

To meet the needs of customers, wide time setting: 0~99 hours, 0~9999 minutes.

All setting operations are prompted with a confirmation sound, which is easy to operate.

It can be controlled remotely using microcomputer software, and the professional supporting operation ALLSENSTM programmable software (optional).

Pro-InsulationTM technology

Based on the concept of effective use of heat energy, the entire inner tank is completely isolated from the outer shell to avoid energy loss due to heat transfer.

The inner tank is wrapped with high-density imported insulation material to effectively insulate and heat preservation.

Good silicone door seal, isolated door hinge design, and door handle with buckle fastening device to ensure tightness.

Sophisticated original imported temperature sensing components

The original imported industrial-grade PT100 temperature sensor has a fast response time and little impact on the self-heating temperature when the temperature changes in steps.

Ergonomic structural design

The color matching of classic products in the modern laboratory, the international popular design, and the arc-shaped design concept add highlights to the laboratory and increase the comfort of operation;

The integrated design of the outer door and the LCD control panel has been developed, which conforms to the ergonomic structure, comfortable Viewing Angle, and the opening of the outer door and the interface are convenient and concise.

Movable mesh partition, the interval and quantity can be adjusted according to customer needs, and the maximum capacity can meet all kinds of experiments and culture items;

Humanized vertical classic structure design, maximizing the use of the working cavity;

The double-door design (equipped with the Incubator series) allows for instant control of the sample status of the inner chamber and better thermal insulation.

Convenient to clean

The concept of easy cleaning is reflected in the circular inner tank around it, and the minimal splicing design is convenient for cleaning and maintenance;

The movable extractable multi-layer partition design makes it easy to clean with fewer metal fittings in the cavity.

Easy to maintain

The LCD microelectronics controller has a diagnostic function, which actually displays various working states and storage, including historical operation and temperature data;

The inner cavity is made of SUS304 stainless steel, which has good anti-corrosion performance and high durability;

The main control and control panel of electrical control components are installed on the upper part of the box, which is convenient for the maintenance and maintenance of the equipment.

Safe and effective protection concept

Multi-parameter abnormal alarm function, and with sound and light prompt;

Automatic double over-temperature safety protection function;

All electronic components are UL certified;

All over-temperature protection devices are designed in accordance with the German DIN 12880 CLass3.1 standard;

The observation window uses explosion-proof and tempered glass for double protection, which effectively improves the safety of operators;

Special shatterproof safety glass panels with flexible suspension and anti-crush protection in the door frame to avoid damage to the operator due to pressure or breakage.

All technical data are tested under no-load conditions, ambient temperature 25°C, Relative Humidity 50%RH, Voltage fluctuation ± 10%, and fully meet the requirements of DIN12880 standards.

Comply with international standards

Temperature safety standard: German DIN 12880 Class 3.1.

Electrical safety standards: IEC 61010-1, UL 61010-1, EN 61010-1.

Kenton KZ-50G LCD Vacuum OvenSpecifications

| LIST | VALUE |

|---|---|

| Thermostat | Ten-stage programmable microcomputer PID intelligent automatic Control system |

| Vacuum meter | digital display |

| Vacuum meter | Electronic automatic control |

| Vacuum range (absolute pressure) | 0~999.9mb |

| Temperature Resolution | ±0.1℃ |

| Temperature Fluctuation | ±0.5℃ |

| Shelf heat transfer technology | have |

| Timer | 0~99h, 0~9999min, optional |

| Temperature range | RT+50~250℃ |

| Volume | 50 liters |

| Environmental temperature | RT+10~30℃ |

| Chamber material | SUS304 stainless steel liner |

| Thermal Insulation | Imported environmentally friendly materials |

| Shelf (std.) | 2pcs |

| Nominal Power | 1250W |

| Power supply Voltage | Single phase AC220V/50Hz |

| Environmental humidity | Below 70% |

Kenton KZ-50G LCD Vacuum Oven Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Kangheng Kenton full series of box equipment selection table

- Electric blast Drying Oven 101 series operation instructions

KZ-50G

KZ-50G