Defelsko PosiTest F Mechanical Coating Thickness Gauge Explosion proof, underwater measurement with certificate

Pointer dial type, no power supply, safe explosion-proof, also suitable for underwater measurement of hot-dip galvanized, hard chrome, paints, enamel on steel and other film thickness, can easily measure cylindrical, factory comes with calibrated certificate.

Defelsko

Defelsko-

PHYNIX Surfix Easy x I-FN HR dual-use Film Thickness Gauge 3000 μm

Login -

Leeb210 coated Film Thickness Gauge Eletroplating, chemical industry, shipbuilding, light industry, automobile and other fields

Login -

Defelsko PosiTector 6000 N0S1 Coating Thickness Gauge non-ferrous metal substrate (such as copper and aluminum) nonconductive coating

$ 1309.00 -

LINSHANG LS225 Coating Thickness Gauge with N1500 probe

$ 599.00 -

Leeb220 Magnetoresistive Thickness Gauge, Non-Magnetic Coating on Magnetic Metal Substrate Film thickness

Login

Introduction to the PosiTest F Mechanical Coating Thickness Gauge

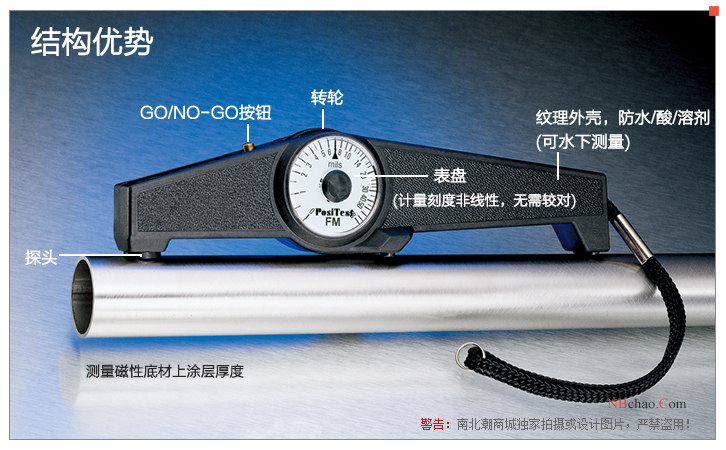

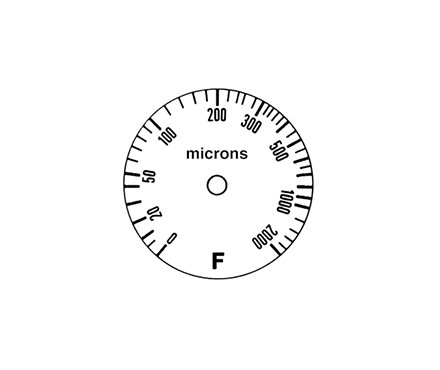

The Defelsko PosiTest F Mechanical Coating Thickness Gauge features a GO/NO-GO button on the top, a thickness scale dial on the front with pulleys on the dial, and a wear-resistant probe with persistent magnetism on the bottom, with a textured housing, making it a mechanical magnetic coating Thickness Gauge. The PosiTest F Mechanical Coating Thickness Gauge has the advantages of simple operation, fast operation, stable and accurate measurement, and the measurement range is 0~2000μm, which is suitable for small parts measurement.

Illustration of the PosiTest F Mechanical Coating Thickness Gauge

Benefits of the PosiTest F Mechanical Coating Thickness Gauge:

1) The thickness measurement is reliable, and the calibration certificate can be traced back to the PTB 2) Textured shell, waterproof, oil, acid, solvent

2) Textured shell, waterproof, oil, acid, solvent

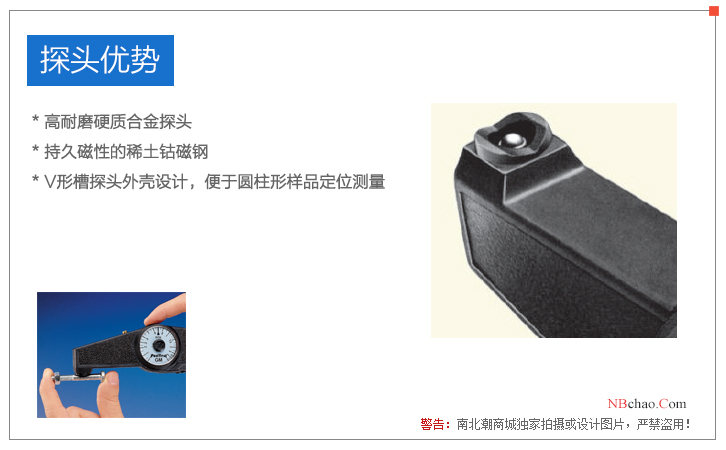

3) The probe is made of high wear-resistant cemented carbide and uses rare earth cobalt magnet with long-lasting magnetism

4) Mechanical, no battery required

5) Measure through the dial and sound prompt

6) Explosion-proof and high safety

7) The included wristband and instruction manual are kept in a high-quality leather case for later use

8) V-groove probe housing, stable and reliable cylindrical measurement

PosiTest F Mechanical Coating Thickness Gauge Operation

1) Place the coating gauge vertically on the object to be measured, so that the probe can touch the surface of the object to be measured.

2) Press the GO/NO-GO button on the PosiTest GM Mechanical Coating Thickness Gauge (i.e., the gold button on the gauge)

3) Gently shake the wheel until you hear a "click", and the thickness indicated by the dial pointer at this moment is the thickness of the coating to be measured.

Comparison of Defelsko PosiTest F&G parameters

| Used for: hot-dip galvanizing, hard chrome, paint, enamel on steel | Used for: electroplating, thin paint film, measurement of phosphating film on steel |

|

|

Measuring range FM: 0~80mil Accuracy FM: ±0.2 mils (within 4mils) ±5% of reading (over 4mils) | Measuring range GM: 0~8mils Accuracy GM: 0.04mils (within 0.8mils) ±5% of reading (over 0.8mils) |

|

|

Measuring range F: 0~2000μm Accuracy F: ±5μm (within 100μm) ±5% of reading (above 100μm) | Measuring range G: 0~200μm Accuracy G: ± 1μm (within 20μm) ±5% of reading (above 20μm) |

Defelsko PosiTest F Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction |

| Measurement range | 0~2000μm |

| margin of error | ±5% |

| application | Hot dip galvanizing, hard chrome, paints, enamel on steel |

Defelsko PosiTest F Coating Thickness Gauge Packing list

Thickness gauge × 1, calibrating certificate × 1, English operation manual × 1, protective bag × 1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle and Application Analysis of Coating Thickness Gauge

- Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- Nondestructive measurement Coating thickness

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveGB/T 42541-2023

- ActiveGB/T 7991.5-2014

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveISO 2178-2016

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- AbolishASTM G12-07-2013

- AbolishISO 2808-2007

PosiTest F

PosiTest F

PosiTest G

PosiTest G