OSP OSP-13 L2000φ 16 Production of custom wire rod 13μm

The Total length of the Japanese OSP-13 production line is 2 meters, and the rod diameter is 16mm. It is a Japanese imported Measurement rod with chrome plating on the surface and good abrasion resistance. The OSP-13 production line rod can be customized with Miscellaneous diameter and length.

OSP

OSP-

Japan OSP-00 L2000φ 16 Custom coating rod Coating Metering rod Smoothing Rods 0μm

Login -

Japan OSP-02 L2000φ 16 Custom coating rod 2μm Spreader roller

Login -

Japan OSP-52 L600/φ 10 wide-wound drawdown Bar Customized Spreader coating bar

Login -

Japan OSP-52 L2000φ 16 Customized Coating Metering rod

Login -

Japan OSP-10 L2000φ 16 Coating Metering rod Spreader stick 10μm/2m

Login

Overview

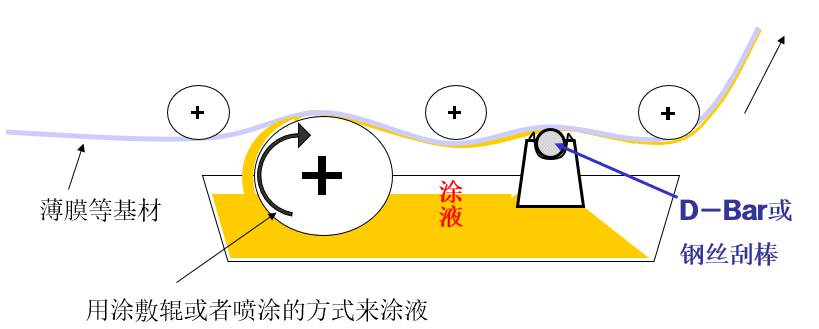

Japan OSP13 micron production profile wire rod (also known as metering rod) is a customized production line rod used to control the flow and maintain the uniformity of the coating in the production machinery and equipment such as paper and film.

OSP OSP-13 L2000 Φ16 production type wire rod is a customized wire rod with a rod diameter of 16mm, a coating width of 2000mm, and a control coating thickness of 13 microns.

D-Bar Advantages:

Customers who use traditional wire scrapers often encounter a wide variety of problems.

(1) The steel wire is loose and broken

(2) It is not easy to clean and easy to block

(3) The surface shape cannot be changed freely

Is there a product that can replace the wire scraper?After several improvements, the D-BAR was finally developed.It was officially launched into the market in 2001.

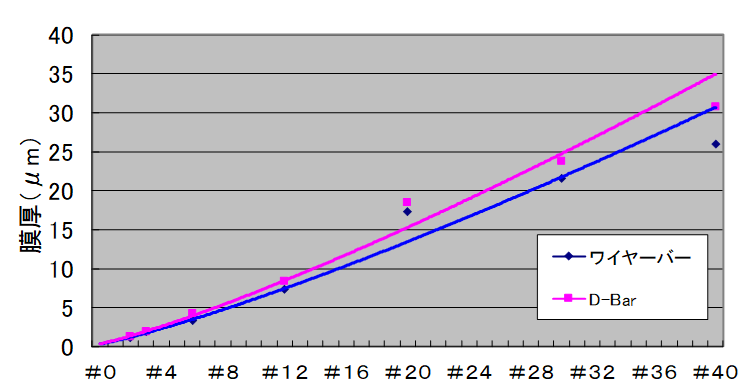

The D-Bar can control wet film thicknesses as low as 1.5 μm, enabling ultra-thin coating

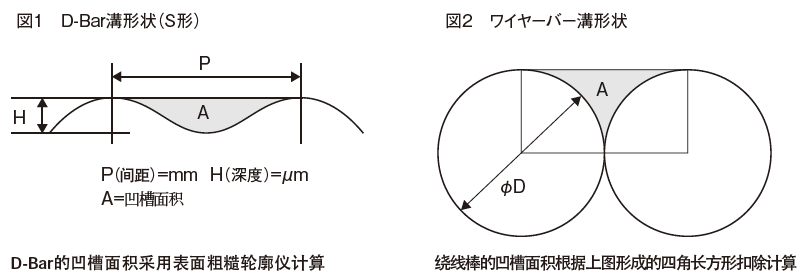

Comparison of the amount of coating on the reel rod and the D-Bar

Difference in coating weight: The bottom of the groove of the D-Bar is wider than that of a conventional wire scraper, so in general, the coating weight of the D-Bar is larger.

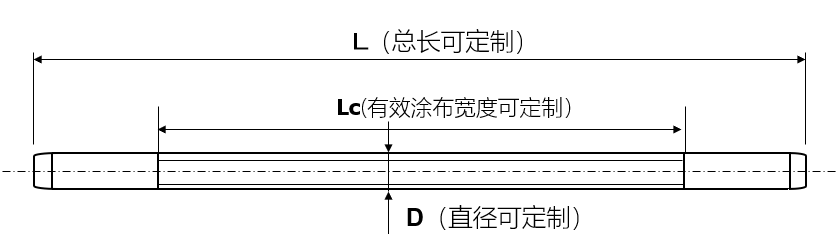

D-Bar line rod specifications

The length of the D-Bar specification can be customized, please contact us for detailsNorth and South Tide customer service

How to use:

When applying liquid to the surface of the substrate, adjust (scrape) the amount of liquid with D-Bar.

Application

The D-Bar series of coating rods for extrusion production produced by OSP in Japan are widely used in the following industries:

Membrane:Liquid crystal film, X-ray film, packaging film, etc

Glass:Automotive glass, liquid crystal glass, architectural glass, etc

Paper:Newspapers, light paper, wallpapers, special papers, etc

Packing Material:Cartons, tapes, wrapping paper, etc

Tape:videotapes, etc

Magnetic card:Tickets, recharge cards, etc

OSP OSP-13 L2000 Φ16 Formed wire scraperSpecifications

| LIST | VALUE |

|---|---|

| WFT | 13μm |

| Total length | 2000mm |

| Effective Spreader Width | 2000mm |

| Main rod diameter | 16mm |

| Surface process | chrome plating |

| Production process | Extrusion process |

| material | 304 stainless steel |

OSP OSP-13 L2000 Φ16 Formed wire scraper Packing list

Custom Spreader Stick × 1, External Encasement Tube

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- The experimental case of OSP Mayer Rods at inks Moulding [with video]

- What problems should I pay attention to when buying a wire rod applicator?

- Nanbei Chao technical engineer tells you: What are often asked when buying a wire rod?

- Frequently Asked Questions for Inventory 2022 Lines, Issue 1

- What wire rod applicator have users in the aluminum profile industry bought?

- Preparation of Ultrafine Silver Nanowire Transparent Conductive Films by Coating Machine + Wire Rod

- What kind of bar applicator have customers in the adhesive industry bought?

- Preparation of fluorescent anti-counterfeiting gravure ink with ink proofing machine

- What are the models of popular bar applicators?

- Which wire rod applicators have the printing industry purchased?

OSP-13 L2000 Φ16

OSP-13 L2000 Φ16