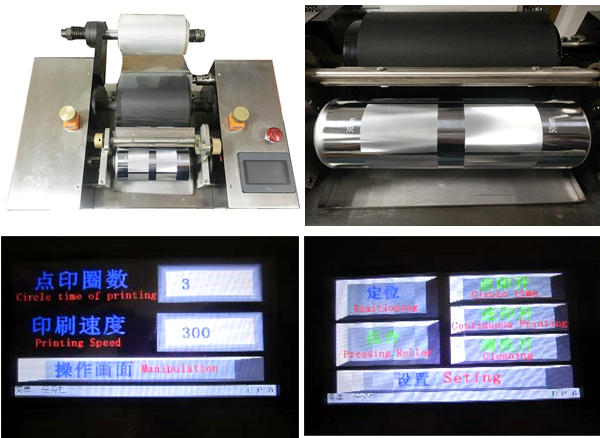

YINUO YN-ZSY-1 gravure printing spot color proofer gravure plate Water-based ink measurement

Touch screen control, automatic positioning, pneumatic pressing, equipped with high-accuracy servo motor and automatic reset system, color bar size 65 * 45mm/P, proofing effective area 110 * 160mm, standard with a layer version.

YiNuo

YiNuo-

MODERNER AYDJ Ink Proofer (Gravure) with D version printability instrument

Login -

JINGHUAYIQI LD-JDY offset plate Ink Proofer printing adaptor

$ 4273.00 -

MODERNER AYDJ inks printing proofing machine (gravure) with B1 version Water-based ink

Login -

HuiNuo HN-AY150 smart Ink Proofer servo numerical control motor, double station discharge

$ 4303.00 -

JINGGONG CP168 Ink Proofer shade test

$ 9228.00

Introduction

YN-ZSY-1 gravure printing spot color proofing machine is designed and produced by simulating the Principle of the printing machine. The pressure of the proofing machine is adjustable and the range of substrates is wide. It is suitable for packaging and printing production, paper production enterprises, ink production enterprises and It is used by scientific research institutions and other departments. The spot color proofing machine can accurately predict the hue of the ink through standard proofing. The correct ratio of the ink is determined by continuously comparing with the color of the standard sample. After the spot color is matched correctly, it will be mass-produced on the printing machine according to the ratio, so that the color matching work is completely transferred to the pre-press work.

Features

1. Operation method: touch screen control, automatic positioning, pneumatic pressing, avoiding errors caused by human operation.

2. Power configuration: Equipped with high-precision servo motor, using Japanese technology servo system

3. Embossing method: embossing in a circular manner, which makes the fit between the pattern and the roller better.

4. The ink is supplied by scraper, and the gravure anilox roller is made by electric engraving or laser engraving, which has higher precision.

5. Equipped with transmission cleaning device: it is more convenient to clean the mesh roller separately from the rubber roller

6. Pre-press position adjustment: configure automatic reset sensor system

7. Anilox roller: different styles of anilox roller can be quickly replaced, and can also be customized according to customer requirements

Precautions

* Viscosity: (generally 3# cup 15-20 seconds viscosity), low viscosity may cause tearing phenomenon, low viscosity can adjust the speed to cooperate.

* Squeegee adjustment: Lines appear in the printed color sample because the scraper is not locked. If lines appear in the blank area, it is caused by scraper chipping. It may be necessary to adjust or replace the scraper.

* Pressure control: If there are pinholes in the printed color sample, adjust the pressure to increase a little bit. If there are creases or tears in the color sample, reduce the pressure appropriately. To prevent the electrostatic adsorption of dust on the film and affect the printing effect, pay attention to the Operating Environment

Standards

GB/T 8941, ISO2813, ISO 2469, ISO 9416, GB/T 7973, GB/T 7974 GB/T 12911, GB/T7706, ASTM D 6531

YiNuo YN-ZSY-1 Gravure plate inksSpecifications

| LIST | VALUE |

|---|---|

| External input Voltage | AC220V, 50HZ-60HZ |

| Complete-built unit power | 220V/50Hz |

| Printing pressure | Pneumatic pressure, the pressure is adjustable from 0 to 1kpa |

| Pressure regulating switch | Pure bronze, diameter 40mm |

| homogenizing speed | 0-300R/min touch screen adjustable |

| Number of screen plates | Standard one layer version (depth 20um, 25um, 30um, 35um, 40um, 45um) |

| Color bar size | 65 * 45mm/P, a total of 6 sets of Cube angles of 90 degrees |

| Screen plate specifications | ø10 * 200mm roller circumference 345.4mm, roller width 190mm |

| Rubber roller hardness | 60 (adhesive film diameter 220mm) |

| Gray scale | 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90%, 100%. Can be customized upon request |

| Proofing effective area | 110*160mm |

| die | Inner diameter 90mm Outer diameter 95mm |

| Printing size | 190 * 600mm (full circumference) |

| Dimensions | 700*570*570mm |

| Complete-built unit net Weight | 140KG |

YiNuo YN-ZSY-1 Gravure plate inks Packing list

complete-built unit X1, manual X1, certificate of conformity X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- How are printing plates made?

- What is inkjet printing?

- How to use flexographic printing to print on plastic film substrates

- How to calculate flexo ink consumption?

- What are the printing substrates and printing inks?

- Influence and Advantages of Scraper Cavity System on Flexographic Printing

- What is pulsed jet printing and what are the advantages and disadvantages?

- Printing ink suitability and paper surface strength

- Tips for Screen Printing on Glass and Ceramic Substrates

- Sustainable printing methods: flexo and screen printing, gravure printing, lithography, offset printing

- IncomingGB/T 17001.3-2025

- IncomingGB/T 17001.4-2025

- ActiveCY/T 104.2-2014

- ActiveCY/T 104.1-2014

- ActiveQB/T 1020-2018

- ActiveCY/T 104.9-2014

- ActiveCY/T 104.7-2014

- ActiveCY/T 104.8-2014

- ActiveCY/T 104.6-2014

- ActiveCY/T 104.4-2014

- ActiveCY/T 104.3-2014

- ActiveCY/T 104.5-2014

- ActiveGB/T 18805-2002

- ActiveISO TS 19857-2021

- ActiveGB/T 33258-2016

- ActiveGB/T 34688-2017

- ActiveGB/T 17001.6-2022

- ActiveGB/T 13217.1-2020

YN-ZSY-1

YN-ZSY-1